Aug . 11, 2024 04:18 Back to list

Supplier of Machines for Manufacturing Air Filters for Trucks and Heavy-Duty Vehicles

The Importance of Truck Air Filters and Reliable Manufacturers

In the world of automotive maintenance, especially for heavy-duty vehicles like trucks, the significance of air filters cannot be overstated. Truck air filters play a crucial role in ensuring that the engine operates efficiently, extends its lifespan, and maintains optimal performance. As demand for these filters grows, so does the need for specialized machinery to manufacture them. This is where truck air filter making machine suppliers come into play.

Air filters in trucks are designed to trap dust, dirt, and other contaminants that could enter the engine. A clean air filter improves fuel efficiency, enhances engine performance, and reduces harmful emissions. Constant exposure to harsh environments makes trucks particularly vulnerable to air quality issues. Therefore, regular inspection and replacement of air filters are essential for any fleet management strategy.

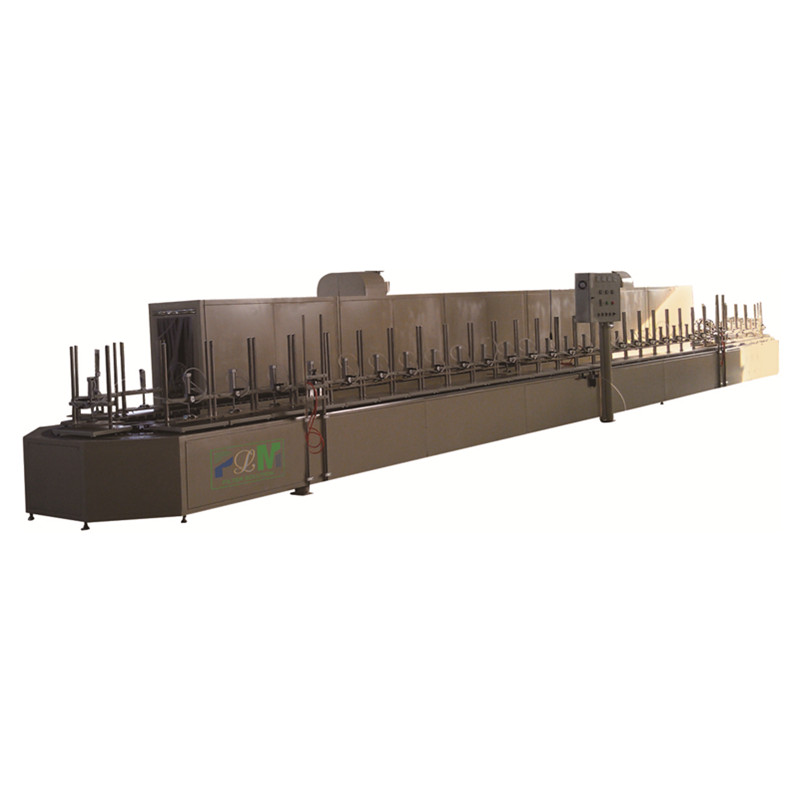

As the demand for high-quality truck air filters rises, the need for advanced manufacturing machinery becomes apparent. Manufacturers of truck air filter making machines focus on delivering technology that not only boosts production efficiency but also ensures that the final product meets industry standards. These machines must produce filters that are both durable and effective, as the cost of downtime for trucks during maintenance can be substantial.

When searching for a supplier of truck air filter making machines, it is imperative to consider a variety of factors. First, the technological sophistication of the machines is paramount. Suppliers that invest in state-of-the-art technology can offer features such as automation, precision cutting, and high-speed production capabilities, which are essential for meeting the growing demands of the market.

truck air filters making machine supplier

Moreover, reliability is a critical aspect when selecting a supplier. The productivity of a manufacturing line hinges on the performance of the equipment. Therefore, a trustworthy supplier should have a proven track record and positive customer reviews. Ensure that they provide adequate support, including training, maintenance, and spare part availability, to minimize downtime and maximize efficiency.

Another essential factor is the range of machinery offered. A larger inventory that includes diverse models allows manufacturers to choose equipment tailored to their specific needs. Whether it's a machine for producing high-flow air filters or one capable of creating specialized filters for certain truck models, having options can significantly enhance the manufacturing process.

Additionally, cost-effectiveness should be considered. While it may be tempting to go for the cheapest option available, the long-term benefits of investing in high-quality machinery often outweigh initial savings. Quality machines tend to have better durability, lower failure rates, and require less frequent maintenance, resulting in lower operational costs over time.

Sustainability is increasingly important in today's manufacturing landscape. Suppliers that prioritize eco-friendly practices in their machinery, such as energy efficiency and waste reduction, will not only help manufacturers align with global sustainability goals but also appeal to a market that increasingly values environmental responsibility.

In conclusion, the role of truck air filters in maintaining engine health and performance cannot be overlooked. As the demand for these filters rises, so too does the need for reliable manufacturing solutions. Collaborating with reputable truck air filter making machine suppliers can lead to enhanced production efficiency, product quality, and long-term operational success. Manufacturers must do their due diligence when selecting a supplier, focusing on technology, reliability, range, cost-effectiveness, and sustainability to ensure they are well-equipped to meet market demands.

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man | Precision Adhesive Application, Efficient Production

NewsAug.15,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man

NewsAug.15,2025

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.15,2025

-

Premium Active Carbon Air Filter for Purifiers - Odor & VOC Removal

NewsAug.15,2025

-

PLAB-6 A B Filter Gluing Machine - Hebei Filter Man

NewsAug.14,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man Automotive Parts Trading Co., Ltd.|Adjustable Speed&Step Motor Control

NewsAug.14,2025