Nov . 12, 2024 11:12 Back to list

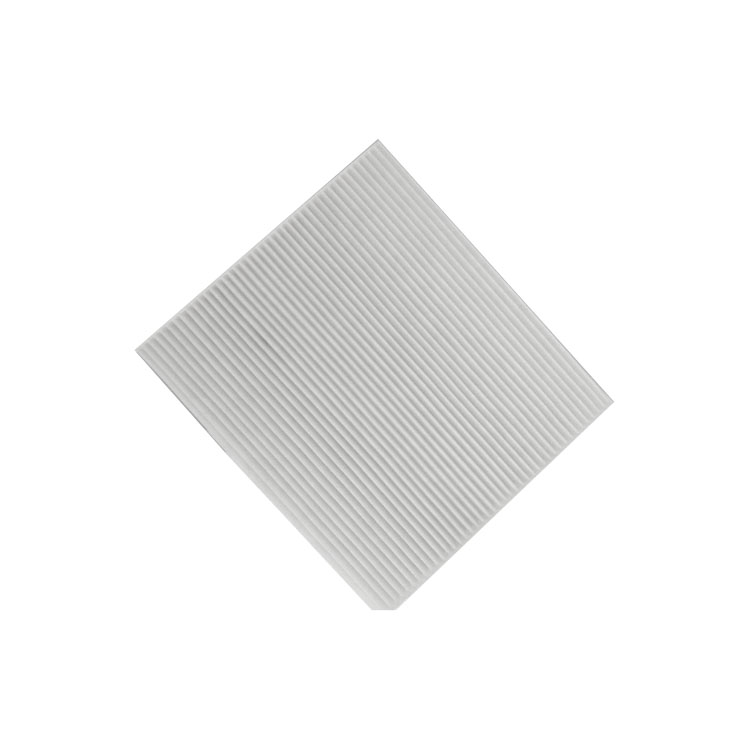

synthetic filter media manufacturer

The Importance of Synthetic Filter Media Manufacturers

In today's rapidly evolving industrial landscape, the need for effective filtration solutions has never been more critical. Synthetic filter media manufacturers play a pivotal role in providing innovative filtration products that cater to various applications across multiple sectors, including automotive, pharmaceuticals, food and beverage, water treatment, and more. This article explores the significance of synthetic filter media, the advantages they offer over traditional materials, and the role manufacturers play in advancing filtration technology.

Understanding Synthetic Filter Media

Synthetic filter media refers to filtration materials made from synthetic fibers, as opposed to traditional natural materials such as paper or cloth. These synthetic fibers are designed to capture particulates, pollutants, and other contaminants from air or liquid streams effectively. The versatility of synthetic filter media allows for a wide range of design options and performance characteristics, making it suitable for various filtration needs.

Advantages of Synthetic Filter Media

1. Higher Filtration Efficiency One of the most significant advantages of synthetic filter media is their high filtration efficiency. They can be engineered to capture a wide range of particle sizes, including ultrafine particles that natural fibers may struggle to trap. This efficiency is especially important in applications where air or liquid quality is paramount, such as in cleanrooms or healthcare settings.

2. Durability and Longevity Synthetic filter media are often more durable than traditional materials. They resist degradation from moisture, chemicals, and temperature fluctuations, leading to longer service life. This durability reduces the frequency of filter replacement, resulting in lower operational costs for industries reliant on filtration systems.

3. Lightweight and Easy to Handle Synthetic fibers are generally lighter than natural alternatives, making them easier to handle and install. This characteristic is particularly advantageous in large-scale filtration systems, where heavy filter media can pose logistical challenges.

4. Customization Synthetic filter media can be customized to meet specific filtration requirements, including pore size, thickness, and surface treatment. This tailor-made approach allows manufacturers to produce filters that perfectly align with the unique demands of their applications, ensuring optimal performance.

synthetic filter media manufacturer

5. Environmentally Friendly Options Many synthetic filter media manufacturers are now focusing on sustainability. They are developing eco-friendly materials that reduce environmental impact while maintaining high filtration effectiveness. This commitment to sustainability resonates with companies looking to maintain their ecological footprints.

The Role of Synthetic Filter Media Manufacturers

Synthetic filter media manufacturers are at the forefront of filtration technology. They are responsible for researching, developing, and producing advanced filter materials. Their work involves a combination of material science, engineering, and innovation to create solutions that meet the rigorous demands of modern industries.

1. Research and Development Continuous R&D is crucial for manufacturers aiming to keep pace with changing filtration requirements. They invest in exploring new materials, technologies, and applications to improve filtration performance and efficiency.

2. Quality Control Ensuring product quality is paramount for manufacturers. They implement stringent quality control processes to guarantee that their filter media meets industry standards and performs as expected in real-world applications.

3. Customer Support and Education Beyond product manufacturing, these companies often provide valuable support to their clients. They assist in selecting the right filtration solutions and offer training on the optimal use and maintenance of their products.

4. Market Adaptation As industries evolve, so do the challenges they face. Synthetic filter media manufacturers must remain agile, adapting their products and services to meet emerging needs, whether prompted by regulatory changes, technological advancements, or shifts in consumer behavior.

Conclusion

Synthetic filter media manufacturers are essential players in the quest for cleaner air and water. Their innovative approaches and dedication to quality are critical in producing filtration solutions that enhance operational efficiency, reduce costs, and ensure environmental compliance. As industries continue to demand more effective and sustainable filtration options, the importance of these manufacturers will only grow, underscoring their role in shaping the future of filtration technology.

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025