Aug . 14, 2024 09:31 Back to list

Top Manufacturers of Semi-Automatic Cabin Air Filter Gluing Machines for Enhanced Efficiency and Precision

The Rise of Semi-Automatic Cabin Air Filter Gluing Machines A Comprehensive Overview

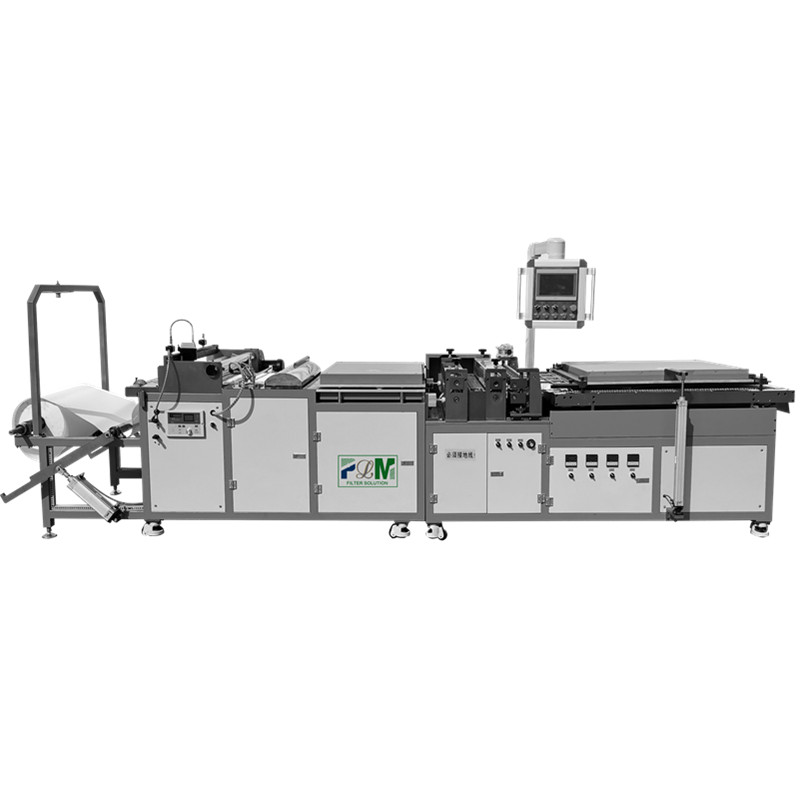

In the ever-evolving landscape of the automotive industry, efficiency and precision are paramount. Among the various components of vehicle manufacturing, cabin air filters play a crucial role in ensuring a comfortable and healthy environment for passengers. The automation of the manufacturing process, particularly in gluing technologies, has garnered immense attention. One of the standout innovations in this domain is the emergence of semi-automatic cabin air filter gluing machines, such as the PLLG-2.

Understanding the Semi-Automatic Gluing Process

Semi-automatic cabin air filter gluing machines are designed to optimize the assembly of air filters, maximizing productivity while maintaining high-quality standards. These machines incorporate advanced technology to streamline the gluing process, reducing human error and enhancing efficiency. By utilizing a combination of manual input and automated functions, these machines cater to a wide range of production scales—from small workshops to larger manufacturing facilities.

The PLLG-2, for instance, features an array of customizable settings that allow manufacturers to adjust the machine according to specific production needs. This adaptability is critical in a landscape where automotive designs and specifications can vary greatly.

Key Benefits of Semi-Automatic Machines

1. Increased Efficiency The PLLG-2 semi-automatic gluing machine reduces cycle times compared to fully manual processes. By automating the gluing steps, manufacturers can produce a higher volume of filters within a shorter timeframe, thus meeting rising market demands.

2. Cost-Effectiveness Although the initial investment in semi-automatic machinery may be substantial, the long-term savings through reduced labor costs and minimized material waste make it a wise financial choice for manufacturers. The precision of these machines often results in better glue application, reducing excess use of adhesive materials.

pllg-2 semi-auto cabin air filter gluing machine manufacturers

3. Consistent Quality Variability in product quality can arise from human error in manual processes. Semi-automatic machines, like the PLLG-2, ensure consistent application of glue, contributing to uniformity in the final product. This reliability is essential for maintaining competitive standards in the automotive market.

4. Flexibility in Production One of the standout features of semi-automatic gluing machines is their ability to accommodate different filter sizes and designs. This versatility allows manufacturers to diversify their product offerings without needing extensive reconfiguration or secondary machinery.

The Future of Air Filter Manufacturing

As environmental concerns continue to drive the automotive sector towards sustainability, the demand for high-performance cabin air filters is set to rise. These filters must not only provide adequate filtration but also ensure low resistance to airflow, improving the vehicle's overall efficiency. Semi-automatic gluing machines play a vital role in this quest, enabling manufacturers to construct filters that meet these stringent performance standards.

Moreover, as manufacturers strive to integrate more automated solutions, the technology behind machines like the PLLG-2 is expected to evolve further. Innovations such as smart sensors, AI integration, and enhanced software for monitoring production quality and efficiency will continue to shape the future of air filter manufacturing.

Conclusion

The advent of semi-automatic cabin air filter gluing machines, exemplified by products like the PLLG-2, represents a significant leap forward in automotive manufacturing technology. By enhancing efficiency, ensuring consistent quality, and providing flexibility, these machines pave the way for a new era in filter production. As the industry continues to adapt to changing demands and sustainability challenges, semi-automatic gluing machines will undoubtedly play a pivotal role in the future of automotive component manufacturing.

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Production

NewsAug.18,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man Automotive Parts Trading Co., Ltd | Adjustable Gluing Parameters, Automated Precision

NewsAug.18,2025

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Engineering&Efficiency

NewsAug.18,2025

-

Active Carbon Air Filter for Purifier: Superior Air Quality & Odor Removal

NewsAug.18,2025

-

PLAB-6 Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Filtering

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.17,2025