Jul . 29, 2024 22:13 Back to list

Top Suppliers for 304mm Rimmed Filter Discs to Meet Your Filtration Needs

The Importance of 304% Rimmed Filter Disc Suppliers in Modern Filtration Systems

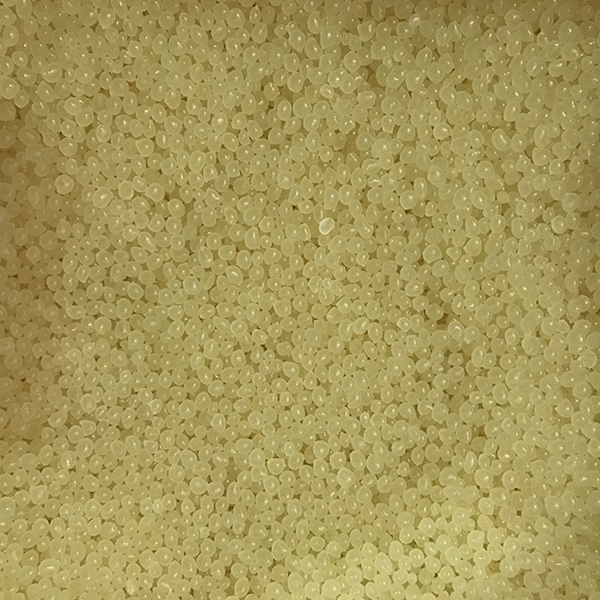

In the realm of industrial filtration, the choice of materials and design greatly impacts the efficiency of the filtration process. Among the various options available, 304 stainless steel rimmed filter discs are gaining considerable attention due to their durability and effectiveness. This article explores the role of 304 rimmed filter disc suppliers, the advantages of using these filter discs, and their applications in different industries.

304 stainless steel is renowned for its excellent corrosion resistance, high tensile strength, and ability to withstand high temperatures. These properties make it an ideal choice for manufacturing filter discs, particularly in demanding environments. Rimmed filter discs, characterized by their reinforced edges, provide additional stability and durability, making them suitable for various filtration applications.

When considering suppliers of 304 rimmed filter discs, it is vital to assess their ability to deliver high-quality products consistently. Reputable suppliers prioritize the quality of their raw materials and employ stringent manufacturing processes to ensure that the final product meets industry standards. They often offer customization options, allowing businesses to specify the size, shape, and mesh size of the filter discs according to their specific filtration needs. This adaptability is crucial, as different industries require unique filtration solutions that can cater to varying fluid characteristics and operational conditions.

One of the significant advantages of using 304 rimmed filter discs is their longevity. Stainless steel does not rust, and the rimmed design prevents the discs from bending or warping under pressure, ensuring an extended service life. This durability translates to lower replacement costs and less downtime in industrial processes, enhancing overall productivity and efficiency.

304 rimmed filter disc suppliers

In addition to their durability, 304 rimmed filter discs allow for efficient filtration. The precise mesh sizes can effectively separate particles from liquids and gases, minimizing contaminants and enhancing the quality of the filtered material. This capability is essential in industries such as food and beverage, pharmaceuticals, and water treatment, where product purity and safety are of utmost importance.

The versatility of 304 rimmed filter discs is also noteworthy. These discs can be used in various filtration applications, including liquid filtration, gas filtration, and even in dust collection systems. Their ability to handle a wide range of temperatures and pressures makes them suitable for use in diverse industrial environments, from chemical processing plants to wastewater treatment facilities.

Furthermore, the sustainability aspect of using stainless steel filter discs cannot be overlooked. As industries worldwide become more environmentally conscious, the need for recyclable and reusable filtration solutions is on the rise. 304 stainless steel is fully recyclable, and by opting for durable rimmed filter discs, companies can significantly reduce their waste footprint. This shift not only contributes to environmental sustainability but also aligns with global trends toward greener practices.

In conclusion, the significance of 304 rimmed filter disc suppliers cannot be underestimated in today’s filtration landscape. Their commitment to quality, customization, and the provision of durable and effective filtration solutions plays a crucial role in helping industries maintain their operational efficiency and product integrity. As businesses continue to navigate the challenges of modern manufacturing and environmental sustainability, the partnership with reliable filter disc suppliers will be essential for success. Investing in high-quality 304 rimmed filter discs is not just a procurement decision; it is a strategic move towards enhancing productivity and sustainability in the long term.

-

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

NewsAug.21,2025

-

Premium Acrylic-Resin Air Filter Paper in Roll | High Efficiency

NewsAug.19,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Production

NewsAug.18,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man Automotive Parts Trading Co., Ltd | Adjustable Gluing Parameters, Automated Precision

NewsAug.18,2025

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Engineering&Efficiency

NewsAug.18,2025

-

Active Carbon Air Filter for Purifier: Superior Air Quality & Odor Removal

NewsAug.18,2025