Jul . 31, 2024 01:21 Back to list

Top Suppliers of PLPY-1% Bursting Strength Testers for Quality Control Solutions

Understanding the PLPY-1% Bursting Strength Tester Key Suppliers and Importance

In the realm of materials testing, the PLPY-1% bursting strength tester plays a crucial role in ensuring the quality and reliability of various materials, particularly in the packaging, textile, and paper industries. This sophisticated equipment measures the resistance of materials to bursting pressure, providing essential data that can directly impact the production process and end product quality. Understanding the significance of this testing method, along with identifying reputable suppliers, is vital for manufacturers seeking to enhance their product offerings.

What is the PLPY-1% Bursting Strength Tester?

The PLPY-1% bursting strength tester is designed to evaluate the bursting strength of materials by applying controlled pressure until the material fails. This test is particularly important for materials like corrugated cardboard, films, and textiles, which must withstand specific pressure levels during handling, storage, and shipping. The 1% in its name refers to a specific measurement method, indicating the sensitivity and precision of the test, which is essential for ensuring compliance with industry standards.

Why Bursting Strength Testing Matters

Bursting strength testing is critical for several reasons. Firstly, it provides manufacturers with quantifiable data regarding the durability of their products. This data is essential not only for internal quality control but also for meeting regulatory standards and customer expectations.

Secondly, knowing the bursting strength of packaging materials can help prevent costly errors. For instance, inadequately tested packaging could lead to failures during transit, resulting in damaged goods and dissatisfied customers. Ultimately, investing in reliable testing equipment like the PLPY-1% tester helps companies improve their reputation and customer trust.

Choosing the Right Supplier

When it comes to purchasing a PLPY-1% bursting strength tester, selecting a reputable supplier is crucial

. Potential buyers should consider factors such as industry experience, product quality, customer service, and after-sales support.plpy-1 bursting strength tester suppliers

1. Industry Experience Suppliers with extensive experience in materials testing equipment are more likely to offer reliable products and expert advice. They are also familiar with the latest industry standards and technological advancements.

2. Quality Assurance Look for suppliers that provide certifications and quality assurances. Equipment that meets international standards ensures consistently accurate testing results.

3. Customer Support Effective after-sales service is essential for maintaining the equipment and troubleshooting any issues that may arise during its use. Suppliers that offer comprehensive support can save manufacturers time and resources in the long run.

4. User Reviews and References Checking reviews and references from other clients can provide insight into a supplier's reliability and the performance of their products. Testimonials and case studies can reveal how others have benefitted from their equipment.

Leading Suppliers in the Market

Several suppliers are known for their high-quality PLPY-1% bursting strength testers. Companies such as Labthink Instruments, Thwing-Albert Instrument Company, and TMI (Testing Machines, Inc.) have established themselves as industry leaders. They not only provide advanced testing solutions but also offer training and technical support to ensure users get the most out of their investments.

Labthink Instruments, for instance, is renowned for its innovative testing equipment and commitment to customer satisfaction. They offer a wide range of materials testing solutions and ensure that their devices are up to date with industry compliance standards.

Conclusion

The PLPY-1% bursting strength tester is an indispensable tool for industries that rely on material durability. By understanding the importance of bursting strength testing and selecting reliable suppliers, manufacturers can significantly enhance their product quality and operational efficiency. Investing in high-quality testing equipment not only safeguards against potential failures but also builds a foundation for long-term success in an increasingly competitive marketplace.

-

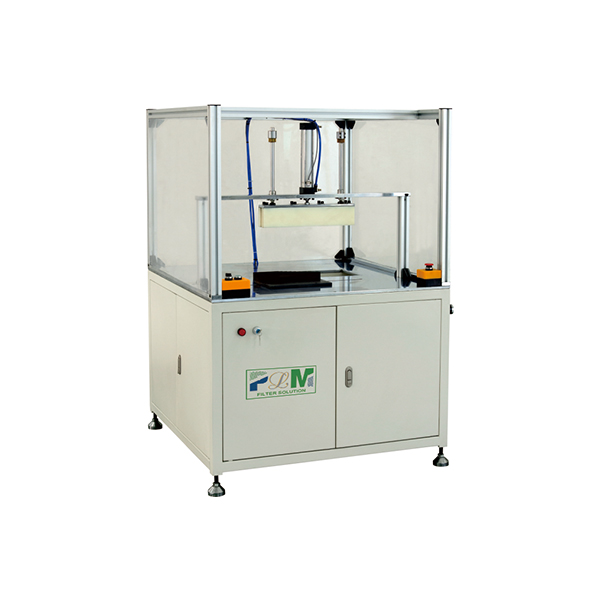

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man | Precision Adhesive Application, Efficient Production

NewsAug.15,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man

NewsAug.15,2025

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.15,2025

-

Premium Active Carbon Air Filter for Purifiers - Odor & VOC Removal

NewsAug.15,2025

-

PLAB-6 A B Filter Gluing Machine - Hebei Filter Man

NewsAug.14,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man Automotive Parts Trading Co., Ltd.|Adjustable Speed&Step Motor Control

NewsAug.14,2025