Jan . 15, 2025 04:44 Back to list

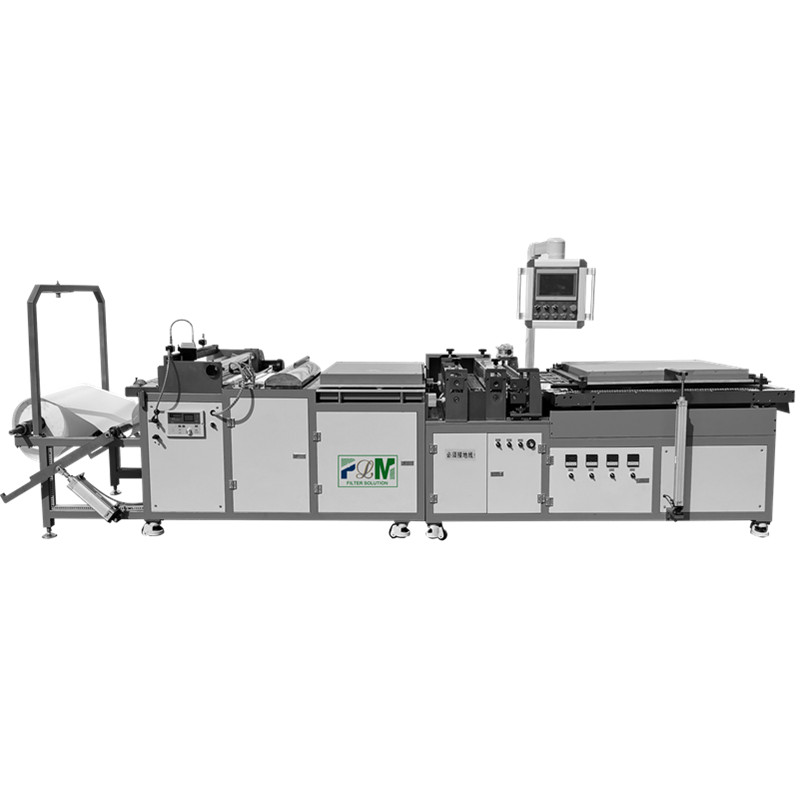

PLPM-1210 Fully Automatic Printing Machine

Trustworthiness in industrial equipment is often demonstrated through compliance with environmental and safety standards. Volute screw presses not only adhere to international standards but often surpass them, providing industries with peace of mind regarding compliance and sustainability. Many manufacturers offer customizable options to fine-tune the equipment to meet specific industrial regulations, thereby bolstering their trust in the market. Apart from their technical prowess, volute screw presses have garnered user trust through consistent performance in challenging environments. Real-world experiences from operators highlight their ability to maintain functionality in harsh conditions, where other dewatering systems might falter. This reliability translates into reduced downtime and maintenance costs, as components are built and tested to withstand the rigors of continuous use. In summary, volute screw presses represent a convergence of engineering excellence, operational efficiency, and environmental responsibility. As industries increasingly prioritize sustainability and cost-effectiveness, the capability of these machines to meet such demands cannot be understated. They not only fulfill their operational role with distinction but also provide strategic advantages in terms of cost savings, compliance, and resource management. For businesses aiming to enhance their dewatering processes, investing in a volute screw press is a testament to forward-thinking and sustainable industrial practice.

Comprehensive Guide to Filter Caps: Applications, Benefits & Future Trends

NewsNov.24,2025Filter Paper: Essential Guide for Industry and Global Applications

NewsNov.23,2025Essential Guide to Filter Materials: Types, Applications, and Future Trends

NewsNov.22,2025Efficient Long Pulse Dust Collector Pleated Filters for Superior Industrial Air Quality

NewsNov.22,2025Professional Air Filter Making Machine – Efficient Air Filtration Production Solutions

NewsNov.21,2025PLAB-6 A/B Glue System-Hebei Filter Man|Precision&Adjustable Speed

NewsNov.21,2025