Aug . 17, 2024 02:36 Back to list

Water Production Equipment for OEM Customized Drinking Water Solutions

The Rise of OEM Drinking Water Making Machines A New Era in Water Production

In recent years, the demand for clean and safe drinking water has surged globally, prompting the development and proliferation of various water purification technologies. Among these, OEM (Original Equipment Manufacturer) drinking water making machines have emerged as a prominent solution for producing high-quality drinking water efficiently and sustainably. These machines not only cater to individual and commercial needs but also play a critical role in addressing the pressing issue of water scarcity.

Understanding OEM Drinking Water Making Machines

OEM drinking water making machines are custom-designed units that are manufactured by third-party companies for various brands or businesses. These machines utilize advanced technologies to purify and bottle water, ensuring it meets quality and safety standards. They come in various capacities and sizes, making them suitable for different applications, from small-scale water bottling plants to large industrial setups.

One of the key advantages of OEM machines is their adaptability. Brands seeking to enter the water production market can collaborate with OEM manufacturers to create tailored solutions that meet their specific requirements. This not only reduces the time and resources needed for research and development but also allows companies to focus on branding and marketing their water products effectively.

The Manufacturing Process

The process begins with the sourcing of raw water, which is typically drawn from natural springs, rivers, or municipal sources. The water undergoes rigorous filtration and purification processes, including sediment filtration, activated carbon filtration, reverse osmosis, and UV disinfection. These steps are crucial for removing impurities, chemicals, and harmful microorganisms, ensuring that the final product is safe for consumption.

The versatility of OEM machines allows for various configurations, such as inline filtration systems, bottling stations, and labeling units. These machines can integrate seamlessly, providing a streamlined operation that enhances efficiency and productivity. Furthermore, the automation features available in these systems help reduce human error and improve overall output quality.

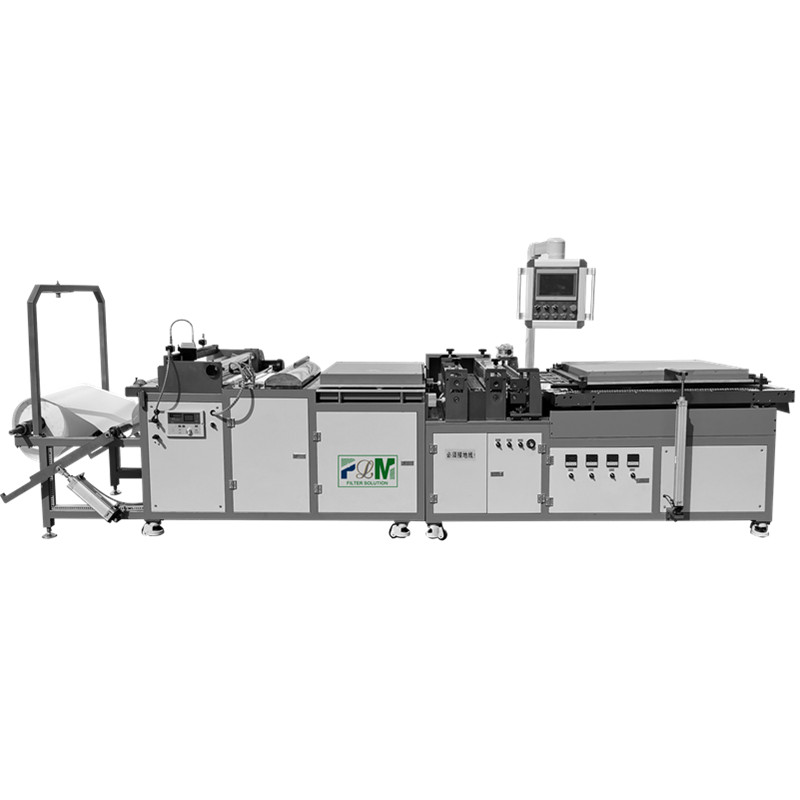

oem drinking water making machine

Environmental Considerations

As concerns about plastic waste and environmental sustainability grow, the water production industry is also evolving. OEM manufacturers are increasingly focusing on eco-friendly practices, such as utilizing biodegradable packaging, reducing energy consumption, and implementing water recycling systems. By investing in sustainable technologies, companies can not only meet consumer expectations but also contribute positively to the environment.

The rise of refillable water stations and bulk vending systems represents a significant shift towards sustainability in the water market. OEM drinking water making machines can be adapted to support these initiatives, allowing businesses to provide clean drinking water while minimizing single-use plastic waste.

The Market Potential

The global bottled water market continues to expand rapidly, driven by rising health consciousness and the increasing preference for convenient hydration options. With the support of OEM drinking water making machines, new businesses can enter the market with lower capital investment and greater confidence.

Moreover, established brands can enhance their production capabilities without the need for extensive infrastructure changes. As a result, the collaboration between brands and OEM manufacturers not only fuels innovation but also creates a competitive landscape that benefits consumers with a wider range of quality drinking water options.

Conclusion

The advent of OEM drinking water making machines is revolutionizing the way safe and clean drinking water is produced and distributed. With their customizable features, efficiency, and sustainability focus, these machines provide an excellent solution for addressing the global water crisis. As the market continues to grow, both new and existing businesses have the opportunity to leverage OEM technologies, making a positive impact on public health and the environment in the process.

Comprehensive Guide to Filter Caps: Applications, Benefits & Future Trends

NewsNov.24,2025Filter Paper: Essential Guide for Industry and Global Applications

NewsNov.23,2025Essential Guide to Filter Materials: Types, Applications, and Future Trends

NewsNov.22,2025Efficient Long Pulse Dust Collector Pleated Filters for Superior Industrial Air Quality

NewsNov.22,2025Professional Air Filter Making Machine – Efficient Air Filtration Production Solutions

NewsNov.21,2025PLAB-6 A/B Glue System-Hebei Filter Man|Precision&Adjustable Speed

NewsNov.21,2025