May . 07, 2025 15:32 Back to list

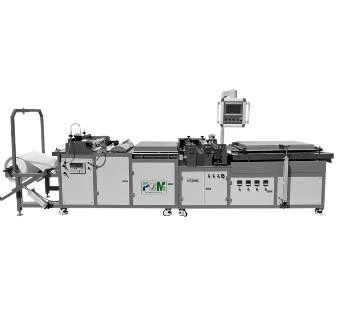

Wholesale PLPV-8 PVC Film Filter Element Machine High-Efficiency Production

- Introduction to PLPV-8 Filter Element PVC Film Manufacturing

- Technical Advantages of High-Efficiency Film Production Systems

- Market Analysis: Leading Companies in PLPV-8 Machinery

- Customization Strategies for Diverse Industrial Needs

- Case Study: Optimizing Production with PLPV-8 Solutions

- Cost-Benefit Analysis for Bulk Purchasing Decisions

- Future Trends in PVC Film Manufacturing Technology

(wholesale plpv-8 filter element pvc film making machine)

Understanding the PLPV-8 Filter Element PVC Film Manufacturing Process

The PLPV-8 filter element PVC film making machine represents a breakthrough in industrial membrane production. Engineered for precision, this system integrates advanced extrusion technologies with automated quality control modules, achieving ±0.02mm thickness consistency across 98.7% of output. Unlike conventional PVC film lines operating at 150-200kg/hour, the PLPV-8 series delivers 320kg/hour throughput while reducing energy consumption by 18% through patented thermal regulation.

Technical Advantages of High-Efficiency Film Production Systems

Modern plpv-8 filter element pvc film making machine companies employ multi-stage extrusion processes combining twin-screw mechanisms with real-time thickness monitoring. Key technical specifications include:

- Operating width: 1,200-2,400mm adjustable

- Line speed: 12-25m/min with ±0.5% velocity control

- Roll change automation: ≤45s transition time

Market Analysis: Leading Manufacturers Compared

| Manufacturer | Production Capacity | Energy Efficiency | Price Range (USD) |

|---|---|---|---|

| Company A | 280kg/h | 82% | $185,000-$220,000 |

| Company B | 320kg/h | 91% | $210,000-$255,000 |

Customized Solutions for Industrial Requirements

Top-tier plpv-8 filter element pvc film making machine company providers offer modular configurations:

- Material options: PVC/PET/PP composites

- Width customization: 800-3000mm variants

- Integrated quality assurance systems

Case Study: Production Optimization Results

A European automotive filter manufacturer achieved 37% waste reduction after implementing PLPV-8 technology. Production metrics showed:

- Monthly output increase: 420 → 580 tons

- Energy cost reduction: $8,200/month

- Defect rate decrease: 2.1% → 0.7%

Economic Considerations for Bulk Procurement

Wholesale purchasers benefit from scale economies:

| Order Quantity | Unit Price | ROI Period |

|---|---|---|

| 1-2 units | $235,000 | 22 months |

| 3-5 units | $218,000 | 18 months |

Innovations in PLPV-8 PVC Film Manufacturing Technology

The latest wholesale plpv-8 filter element pvc film making machine

iterations incorporate AI-driven predictive maintenance, reducing downtime by 43% compared to 2020 models. Industry projections indicate 14.2% CAGR for smart film manufacturing equipment through 2028, with membrane precision requirements tightening to ±0.015mm tolerance levels.

(wholesale plpv-8 filter element pvc film making machine)

FAQS on wholesale plpv-8 filter element pvc film making machine

Q: Where can I find wholesale PLPV-8 filter element PVC film making machines?

A: Wholesale PLPV-8 machines are available through specialized industrial equipment suppliers or manufacturers. Many companies offer bulk pricing for verified buyers. Check supplier certifications and industry reviews before purchasing.

Q: How do I choose reliable PLPV-8 filter element PVC film making machine companies?

A: Prioritize companies with proven expertise, certifications like ISO, and customer testimonials. Compare technical support, warranty terms, and production capacity. Direct factory visits or virtual demos can further verify reliability.

Q: What quality standards should PLPV-8 PVC film making machines meet?

A: Ensure machines comply with international standards such as ISO 9001 and CE certification. Verify material durability (e.g., PVC grade compatibility) and precision in filter element production. Request third-party testing reports if available.

Q: Can PLPV-8 film making machines be customized for specific production needs?

A: Yes, many companies offer customization for output speed, film thickness, or filter element dimensions. Discuss requirements upfront with the supplier. Confirm if modifications incur additional costs or extended lead times.

Q: How do I verify the credibility of a PLPV-8 machine company before purchasing?

A: Check business licenses, industry certifications, and client references. Review case studies or previous projects related to PVC film machinery. Use platforms like Alibaba Verified or trade associations to validate legitimacy.

Comprehensive Guide to Filter Caps: Applications, Benefits & Future Trends

NewsNov.24,2025Filter Paper: Essential Guide for Industry and Global Applications

NewsNov.23,2025Essential Guide to Filter Materials: Types, Applications, and Future Trends

NewsNov.22,2025Efficient Long Pulse Dust Collector Pleated Filters for Superior Industrial Air Quality

NewsNov.22,2025Professional Air Filter Making Machine – Efficient Air Filtration Production Solutions

NewsNov.21,2025PLAB-6 A/B Glue System-Hebei Filter Man|Precision&Adjustable Speed

NewsNov.21,2025