Oct . 22, 2024 10:06 Back to list

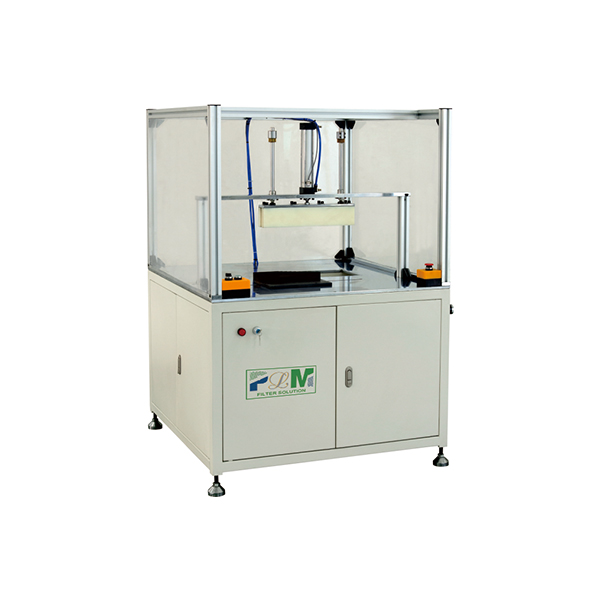

plpg-350 full-auto panel air filter paper pleating production line

The PLPG-350 full-auto panel air filter paper pleating production line represents a significant advancement in the manufacturing of air filters. With the increasing demand for efficient air filtration in various industries, this innovative production line is designed to streamline the pleating process, enhance productivity, and improve the overall quality of air filter products.

At its core, the PLPG-350 is equipped with cutting-edge technology that automates the entire pleating procedure. This automation not only reduces the need for manual labor but also minimizes human error, ensuring a consistent and high-quality output. The production line operates at an impressive speed, capable of producing a large volume of pleated filter media in a short period. This efficiency is crucial in meeting the growing market demand for air filters, especially in sectors such as HVAC, automotive, and industrial applications.

One of the standout features of the PLPG-350 is its versatility. It can handle various types of filter media, including synthetic fibers and cellulose, allowing manufacturers to produce a wide range of filter specifications to meet different customer requirements. The machine is also designed for easy adjustments, enabling quick changeovers between different pleating patterns and sizes, which is essential for companies that need to supply customized filter solutions.

plpg-350 full-auto panel air filter paper pleating production line

Quality control is paramount in the production of air filters, and the PLPG-350 incorporates advanced monitoring systems that ensure each pleated panel meets rigorous standards. With integrated sensors and quality assurance protocols, manufacturers can rest assured that their products will perform effectively, providing optimal air filtration for end users. This commitment to quality not only enhances customer satisfaction but also strengthens brand reputation in a competitive market.

Sustainability is another key consideration in modern manufacturing, and the PLPG-350 is designed with eco-friendly features. Its efficient use of materials minimizes waste, and the technology allows for recycling of scrap filter media, supporting environmentally responsible practices. As industries globally strive to reduce their carbon footprint, investing in sustainable production methods is becoming increasingly important.

In conclusion, the PLPG-350 full-auto panel air filter paper pleating production line is an excellent investment for manufacturers looking to enhance their production capabilities. Its advanced technology, efficiency, versatility, and commitment to quality and sustainability make it a vital asset for businesses in the air filtration industry. By adopting such innovative solutions, manufacturers can not only improve their operational performance but also contribute to a cleaner and healthier environment.

-

OEM PLKJ-20 Filter Paper Pore Size Tester Precision Measurement

NewsMay.19,2025

-

Affordable PLNP-1 Bursting Strength Tester Low-Cost & Reliable

NewsMay.19,2025

-

Premium Toyota Air Filter Machines OEM Suppliers & Manufacturers

NewsMay.19,2025

-

OEM Truck Air Filters Machine Production Line - Custom Solutions

NewsMay.18,2025

-

Toyota Air Filter Producing Machine High-Efficiency Manufacturing Solutions

NewsMay.18,2025

-

Affordable Truck Air Filters High Quality & Low Cost

NewsMay.18,2025