ਨਵੰ. . 10, 2024 09:40 Back to list

Automated 16-Station Turntable Curing Production Line for Enhanced Efficiency

Exploring the OEM PLTK-16 Full-Auto 16-Station HDAF Turntable Curing Production Line

In the ever-evolving landscape of industrial manufacturing, the need for efficiency, precision, and versatility has never been more critical. One of the latest innovations in this field is the OEM PLTK-16 Full-Auto 16-Station HDAF Turntable Curing Production Line. This sophisticated piece of machinery is designed to streamline the curing process, a vital step in various manufacturing sectors, particularly in the production of composite materials and other heat-sensitive products.

The Importance of Curing

Curing is the process of hardening materials through a chemical reaction, typically involving heat or chemical catalysts. It plays a crucial role in enhancing the durability and performance of products. In industries such as automotive, aerospace, and electronics, the quality of the final product greatly depends on the efficiency and effectiveness of the curing process. The technological advancements in curing systems have made it possible to achieve tighter tolerances and better mechanical properties in the resulting materials.

Features of the PLTK-16

The OEM PLTK-16 is engineered with advanced features that make it a game-changer in curing technology. One of its standout characteristics is its 16-station turntable design, which allows for simultaneous curing of multiple components. This capability significantly increases throughput while ensuring consistency and precision across all curing stages.

Automated Operation

Automation is at the heart of the PLTK-16 system. Its full-auto operation minimizes the need for manual intervention, thereby reducing the likelihood of human error and enhancing overall safety. Operators can monitor the process remotely via an intuitive interface, adjusting settings such as temperature and curing time as needed. This level of control ensures that each product receives the optimal conditions for curing, leading to higher quality outputs.

HDAF Technology

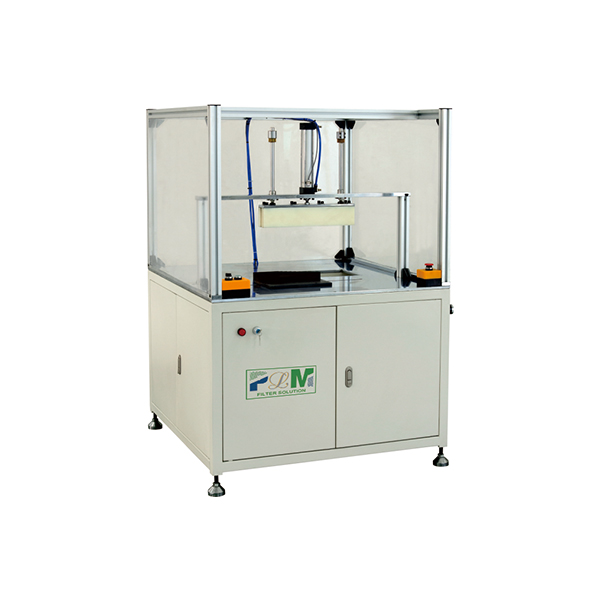

oem pltk-16 full-auto 16-station hdaf turntable curing production line

The HDAF (High-Density Automated Flow) technology utilized in the PLTK-16 further elevates its performance. This innovative system allows for efficient heat distribution, which is critical in ensuring uniform curing across all stations. The technology not only shortens the curing time but also enhances energy efficiency, reducing operating costs and environmental impact.

Versatility Across Industries

The versatility of the PLTK-16 makes it suitable for a wide range of applications. Whether dealing with thermosetting plastics, composites, or elastomers, this production line can be customized to meet diverse production requirements. Its ability to handle various materials means manufacturers can adapt quickly to changing market demands, making it a vital asset in competitive industries.

Long-term Cost Efficiency

Investing in a PLTK-16 Full-Auto 16-Station HDAF Turntable Curing Production Line can lead to substantial long-term cost savings. The increased throughput combined with lower energy consumption results in higher productivity without compromising quality. Moreover, the reduced scrap rates due to more precise curing processes mean that manufacturers can maximize their yield, ultimately impacting their bottom line positively.

Conclusion

In conclusion, the OEM PLTK-16 Full-Auto 16-Station HDAF Turntable Curing Production Line represents a significant leap forward in curing technology. With its advanced automated features, efficient heat distribution system, and versatility, it stands to revolutionize the way manufacturers approach the curing process. As industries continue to evolve and seek out innovative solutions to meet growing demands, the PLTK-16 offers a robust and efficient pathway to enhanced productivity and quality.

For manufacturers aiming to stay at the forefront of technology while optimizing their production lines, investing in state-of-the-art equipment like the PLTK-16 is not just advantageous—it's essential. With the ongoing advancements in manufacturing processes, innovations like the PLTK-16 pave the way for a brighter, more efficient industrial future.

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025