sty . 17, 2025 00:50 Back to list

industrial air filter

In the rapidly advancing industrial landscape, maintaining air quality is crucial not only for regulatory compliance but also for ensuring the health and safety of workers. Industrial air filters play a significant role in this regard, serving as a primary defense against airborne contaminants in various industrial environments. Understanding the fundamentals of industrial air filters is essential for businesses aiming to optimize operational efficiency and maintain a safe workplace.

Authoritative knowledge about compliance and regulatory standards is also essential. Different regions may have specific regulatory requirements concerning air quality, necessitating compliance with local laws and guidelines. Being well-versed with organizations such as the Environmental Protection Agency (EPA) standards or the Occupational Safety and Health Administration (OSHA) guidelines can provide a competitive edge in ensuring regulatory compliance and enhancing trustworthiness with clients and stakeholders. In today's data-driven world, integrating smart technology with industrial air filters is an emerging trend that enhances their efficiency and reliability. IoT-enabled air filters come with advanced sensors that can monitor air quality in real-time and provide predictive maintenance alerts, ensuring timely interventions and reducing downtime. Such technologies not only ensure the reliability of air filtration but also contribute to operational savings and enhanced workplace safety. Investing in high-quality industrial air filters is a decision that reflects a company's commitment to operational excellence and employee well-being. Companies that prioritize air quality can see a marked improvement in worker productivity and morale, reduced health-related absences, and an overall improvement in industrial processes. Trust in industrial air filters comes not just from their immediate benefits but also from their long-term contribution to a safe and compliant working environment. In conclusion, the role of industrial air filters extends beyond merely purifying air. They are integral components of a comprehensive approach to workplace safety and operational efficiency. Expertise in selecting, maintaining, and utilizing these filters not only contributes to regulatory compliance and cost savings but also reinforces a company's commitment to sustainability and employee health. By staying informed about the latest advancements and regulatory requirements, businesses can ensure they are not only protecting their operations but also their most valuable asset—their workforce.

Authoritative knowledge about compliance and regulatory standards is also essential. Different regions may have specific regulatory requirements concerning air quality, necessitating compliance with local laws and guidelines. Being well-versed with organizations such as the Environmental Protection Agency (EPA) standards or the Occupational Safety and Health Administration (OSHA) guidelines can provide a competitive edge in ensuring regulatory compliance and enhancing trustworthiness with clients and stakeholders. In today's data-driven world, integrating smart technology with industrial air filters is an emerging trend that enhances their efficiency and reliability. IoT-enabled air filters come with advanced sensors that can monitor air quality in real-time and provide predictive maintenance alerts, ensuring timely interventions and reducing downtime. Such technologies not only ensure the reliability of air filtration but also contribute to operational savings and enhanced workplace safety. Investing in high-quality industrial air filters is a decision that reflects a company's commitment to operational excellence and employee well-being. Companies that prioritize air quality can see a marked improvement in worker productivity and morale, reduced health-related absences, and an overall improvement in industrial processes. Trust in industrial air filters comes not just from their immediate benefits but also from their long-term contribution to a safe and compliant working environment. In conclusion, the role of industrial air filters extends beyond merely purifying air. They are integral components of a comprehensive approach to workplace safety and operational efficiency. Expertise in selecting, maintaining, and utilizing these filters not only contributes to regulatory compliance and cost savings but also reinforces a company's commitment to sustainability and employee health. By staying informed about the latest advancements and regulatory requirements, businesses can ensure they are not only protecting their operations but also their most valuable asset—their workforce.

Next:

Latest news

-

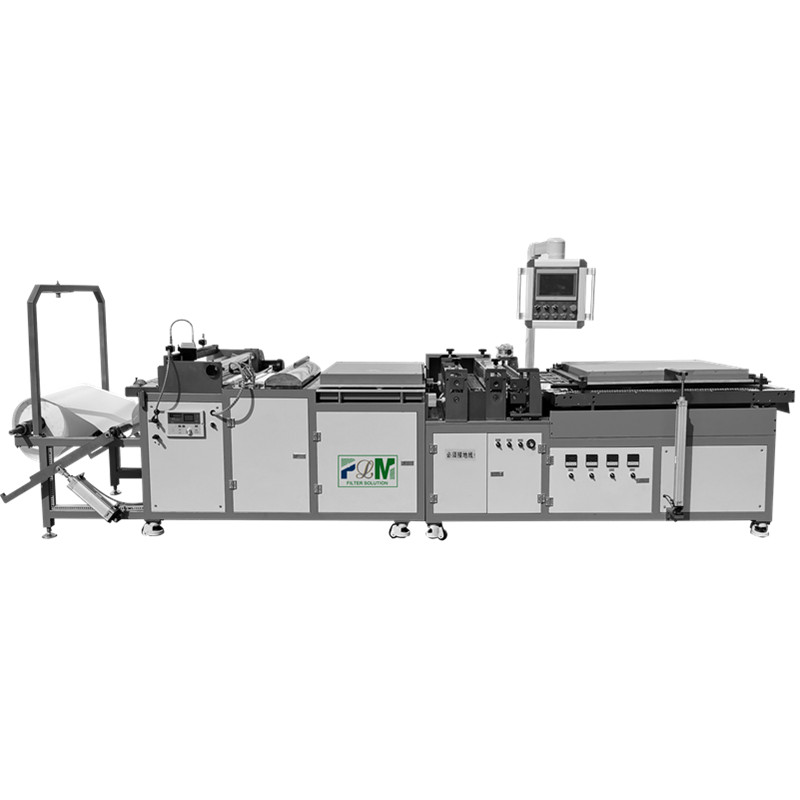

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025