Nov . 26, 2024 14:22 Back to list

Supplier of Spiral Filter Core Production Equipment and Machines

The Rise of Spiral Filter Core Making Machine Suppliers

In recent years, the demand for efficient and reliable filtration systems has surged across various industries, such as automotive, aerospace, pharmaceuticals, and food and beverage. A critical component of these systems is the filter core, which is essential for maintaining the quality and safety of the final products. Consequently, the market for spiral filter core making machines has experienced significant growth, with many suppliers emerging to meet the increasing demands of manufacturers.

A spiral filter core is characterized by its unique design that allows for enhanced filtration efficiency. This type of filter core is made by winding layers of filter media around a central support structure, creating a spiral design that increases the surface area and improves the flow dynamics. The machines used to manufacture these filter cores need to be highly specialized to ensure precision and consistency in production.

Choosing the Right Supplier

When selecting a spiral filter core making machine supplier, several factors should be considered to ensure that the top quality machinery is obtained. Firstly, it's essential to evaluate the supplier's reputation in the market. Established suppliers often have a track record of delivering high-quality machines and services. Reading reviews, seeking referrals, and examining case studies can provide insights into a supplier’s reliability.

Secondly, the technological capabilities of the machine are paramount. A good supplier will offer cutting-edge technology that can accommodate various filter media types, adapt to different production speeds, and ensure scalability. Advanced features such as automated controls, integrated quality checks, and user-friendly interfaces enhance operational efficiency and reduce human error.

Another critical factor is the level of customer support and after-sales service provided by the supplier. Machines for manufacturing spiral filter cores often require ongoing maintenance and technical support. A reputable supplier will offer comprehensive training for operators, timely maintenance services, and readily available spare parts to minimize downtime and ensure that production flows smoothly.

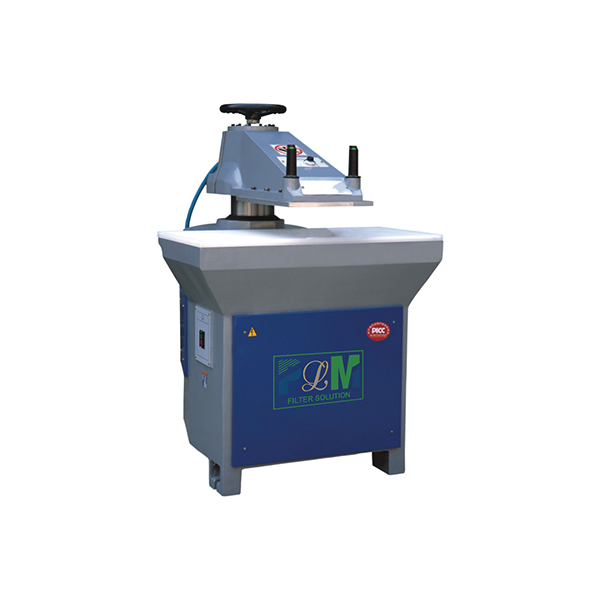

spiral filter core making machine supplier

Customization and Flexibility

In today’s manufacturing landscape, customization is key. Each customer may have unique requirements regarding filter core dimensions, materials, and production volumes. Leading suppliers recognize this need for flexibility and offer customizable solutions that cater to individual client specifications. This means that manufacturers can optimize their production processes, resulting in improved efficiency and reduced costs.

The trend towards automation is also shaping the spiral filter core making machine market. Suppliers are increasingly integrating smart technology into their machines, enabling remote monitoring and diagnostics. This automation allows manufacturers to optimize their operations, increase production efficiency, and maintain consistent product quality.

Sustainability Considerations

Moreover, with the growing emphasis on sustainability and environmental responsibility, suppliers are also focusing on producing machines that minimize waste and energy consumption. Innovations in materials and processes can result in a reduced carbon footprint, catering to environmentally conscious manufacturers.

Conclusion

The landscape of spiral filter core making machine suppliers is evolving rapidly, driven by the need for high-quality filtration solutions across various industries. As the demand for these machines continues to rise, it is crucial for manufacturers to carefully consider their options when choosing a supplier. By focusing on reputation, technological capabilities, customer support, and customization options, businesses can secure the right machinery to meet their needs. Embracing advancements in automation and sustainability will not only enhance operational efficiency but also position manufacturers favorably in an increasingly competitive market. With the right partner, manufacturers can ensure that they remain at the forefront of filtration technology, delivering superior products to their customers.

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025