Дек . 06, 2024 01:29 Back to list

Exploring Filter Rolls for Enhanced Media Product Performance

Exploring Filter Rolls in Media Products A Comprehensive Overview

In the ever-evolving world of media products, the utilization of filter rolls has gained significant attention due to their pivotal role in enhancing the quality and performance of various media applications. From printing to packaging and from photographic processes to digital imaging, filter rolls serve as essential components that streamline activities, reduce waste, and improve the overall output. This article aims to explore the significance of filter rolls in media products, their types, applications, and the innovations revolutionizing their use.

Understanding Filter Rolls

Filter rolls are specialized materials designed to remove impurities, contaminants, and unwanted particles from liquids and gases. They work through various filtration processes, including mechanical filtration, absorption, and depth filtration. The effectiveness of filter rolls often depends on their composition, pore size, and design, which are tailored to meet specific industry needs. In the realm of media products, these filters are integrated into various forms of technology and processes that require precise quality control.

Types of Filter Rolls

1. Synthetic Filter Rolls Composed of man-made materials, synthetic filter rolls offer excellent durability and resistance to chemical degradation. Common materials include polyester and polypropylene, which allow for high flow rates and superior filtration efficiency.

2. Fiberglass Filter Rolls Used extensively in air and liquid filtration, fiberglass filters possess high dirt-holding capacity and are capable of capturing very fine particles, making them ideal for applications requiring high purity.

3. Cellulose Filter Rolls These are primarily used in the food and beverage industries. They are biodegradable and provide an economical solution without compromising the purity and quality of the product.

4. Activated Carbon Filter Rolls Known for their excellent adsorption properties, activated carbon filters are pivotal in applications requiring odor and taste removal, particularly in drinking water and air filtration.

Applications in Media Products

Filter rolls find diverse applications across several sectors of media production and consumption

filter rolls media products

- Printing Industry In printing processes, filter rolls help maintain the quality of inks and solvents, ensuring that impurities do not compromise the printing output. They prevent clogging in inkjet printers, enhancing performance and reducing downtime.

- Packaging In the food packaging sector, filter rolls act as barriers to harmful contaminants, thus ensuring the safety and longevity of products. Their use in vacuum packaging systems is particularly noteworthy, as it helps retain flavor and freshness.

- Photographic Processes Filter rolls play a critical role in developing photographic materials, where the filtration of chemicals is essential to producing high-quality images. They aid in achieving consistent results across various batches.

- Digital Imaging In digital imaging, filter rolls are integral in managing waste and enhancing the quality of the final output. As digital devices evolve, the filtration of materials used in the production of imaging devices becomes crucial to maintaining high standards.

Innovations and Trends

The landscape of filter rolls is witnessing significant innovations aimed at enhancing efficiency and sustainability. Notable trends include

- Eco-friendly Materials With rising environmental concerns, manufacturers are increasingly focusing on biodegradable and recyclable materials, reducing the ecological footprint of filter rolls.

- Smart Filtering Technology The integration of monitoring systems allows for real-time tracking of filter performance. These advanced systems can alert users when filters need replacing, thereby preventing downtime and maintaining operational efficiency.

- Customization As media production processes become increasingly specialized, the demand for customizable filter rolls is on the rise. Manufacturers are developing tailor-made solutions to meet specific filtration requirements, improving effectiveness across diverse applications.

Conclusion

Filter rolls are a cornerstone in the production and processing of media products, enhancing quality, efficiency, and safety. As technology advances and industries evolve, the importance of innovative filtration solutions continues to grow. Stakeholders in the media sector must remain attuned to the latest developments in filter technology to ensure they capitalize on its benefits and meet the ever-expanding demands of consumers. With a focus on sustainability and customization, the future of filter rolls in media products looks promising and essential for better performance across industries.

-

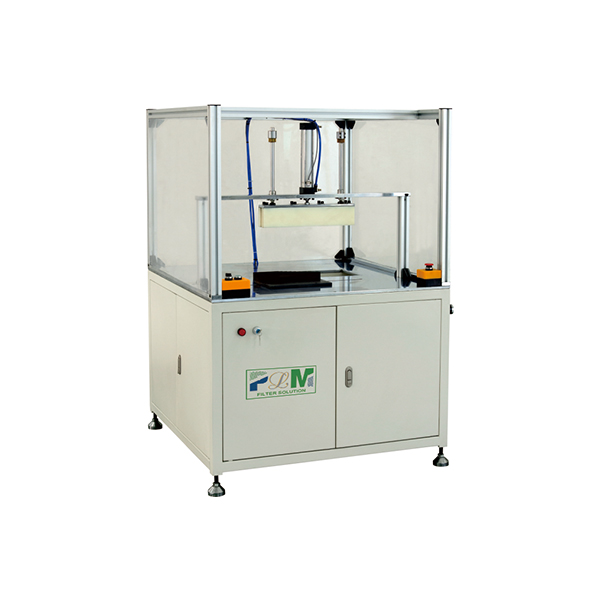

OEM PLXB-1 PU Pack Trimming Machine - Precision Cutting, High Efficiency, Reliable Quality

NewsJul.05,2025

-

Premium Engine Oil Filter Supplier & Exporter Reliable Engine Oil Filter Service

NewsJul.04,2025

-

Wholesale PLRZ-1000N Full-Auto Hot Melt Filter Paper Bonding Machine - High Efficiency & Precision

NewsJul.04,2025

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025