Dec . 22, 2024 18:15 Back to list

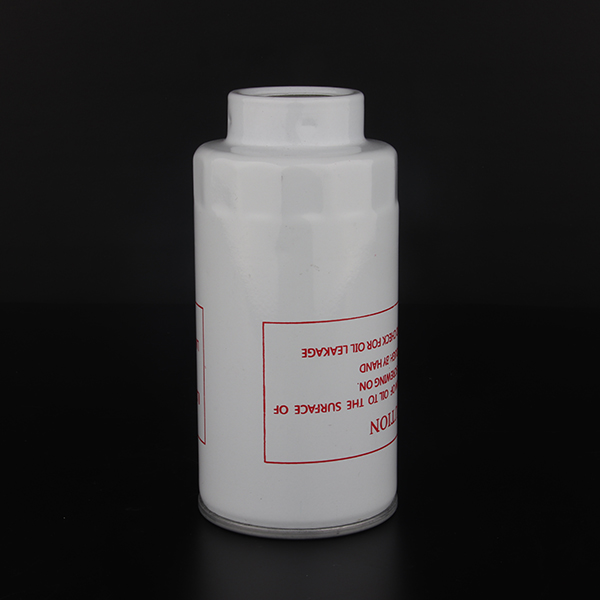

china filter mould

The Importance of China Filter Mould in Industrial Applications

In the contemporary industrial landscape, the demand for efficient filtration systems has surged as companies strive to meet stringent environmental regulations and improve product quality. Among the essential components of these systems is the filter mould, particularly those produced in China, known for their high quality and innovative designs. This article delves into the significance of China filter mould, its applications, and the factors contributing to its rising prominence in the global market.

Understanding Filter Mould

Filter moulds are specialized tools used in the production of filters that separate particles from liquids and gases. These filters are vital in various industries, including automotive, pharmaceutical, food and beverage, and wastewater treatment. The production of filter moulds involves precision engineering, as the dimensions and shapes of the filters must be exact to ensure optimal performance.

China's Dominance in Filter Mould Production

China has emerged as a leading player in the global filter mould market, thanks to several factors. First and foremost, the country boasts a robust manufacturing infrastructure and a vast pool of skilled labor, which allows for the efficient production of high-quality moulds at competitive prices. Chinese manufacturers leverage advanced technologies and materials, enabling them to produce filter moulds that meet international standards.

Another contributing factor is the abundance of raw materials in China. The country is rich in the resources required for manufacturing filter moulds, such as plastics and metals, allowing for the consistent supply of high-quality components. This vertical integration of resources helps reduce costs and improve the overall efficiency of the production process.

Applications of China Filter Mould

china filter mould

The applications of filter moulds produced in China are vast and varied. In the automotive industry, filters play a crucial role in maintaining engine performance and reducing emissions. Filter moulds are used to produce oil, air, and fuel filters that help ensure vehicles run smoothly and comply with environmental regulations.

In the pharmaceutical sector, filter moulds are essential for producing filters that ensure the purity of drugs and other healthcare products. These filters must meet stringent quality standards, making the precision of the moulds critical to product safety and efficacy.

The food and beverage industry also relies on filter moulds for producing filters that remove impurities from liquids, such as water and juices. Ensuring the quality of beverages is paramount, and filter moulds help manufacturers maintain the highest standards.

Moreover, in the wastewater treatment sector, filter moulds are used to create filters that help purify water before it is released back into the environment. With increasing concerns about environmental sustainability, the demand for effective filtration systems has surged, further driving the growth of the filter mould industry in China.

Future Prospects

Looking ahead, the future of China filter mould appears promising. As industries continue to evolve and new technologies emerge, the need for advanced filtration solutions will only grow. Chinese manufacturers are well-positioned to capitalize on this trend by investing in research and development to create innovative mould designs and materials.

In conclusion, China filter mould plays a vital role in various industrial applications, contributing to improved efficiency, product quality, and environmental sustainability. With its competitive advantages in manufacturing, resource availability, and technological advancement, China is set to remain a key player in the global filter mould market for years to come. The ongoing commitment to quality and innovation will ensure that Chinese filter moulds continue to meet the evolving needs of industries worldwide.

-

Premium Acrylic-Resin Air Filter Paper in Roll | High Efficiency

NewsAug.19,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Production

NewsAug.18,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man Automotive Parts Trading Co., Ltd | Adjustable Gluing Parameters, Automated Precision

NewsAug.18,2025

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Engineering&Efficiency

NewsAug.18,2025

-

Active Carbon Air Filter for Purifier: Superior Air Quality & Odor Removal

NewsAug.18,2025

-

PLAB-6 Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Filtering

NewsAug.17,2025