Dec . 05, 2024 08:59 Back to list

Full Automatic Rotary Eco Filter Paper Pleating Production Line Supplier

The PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line An Innovative Solution for Modern Filtration Needs

In today’s industrial landscape, efficiency and sustainability are crucial. The PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line represents a significant advancement in filter paper manufacturing, catering to the growing demands of various industries while promoting eco-friendly practices.

Overview of the PLGT-600N

The PLGT-600N is designed to automize the pleating process of filter paper, a critical component in air and liquid filtration systems. Its advanced technology allows for high-speed production, ensuring that manufacturers can meet tight deadlines without compromising on quality. This machine integrates various functions including feeding, pleating, and cutting, streamlining the production process and reducing labor costs.

Key Features

1. High Production Capacity The PLGT-600N is capable of producing filter paper at an impressive speed, significantly reducing lead times for orders. This is particularly beneficial for companies that operate in industries requiring fast turnaround times, such as automotive, HVAC, and water treatment.

2. Eco-Friendly Design In an era where environmental concerns are top of mind, the PLGT-600N stands out with its eco-friendly features. The production line has been engineered to minimize waste and energy consumption, aligning with the global push towards sustainable manufacturing practices. The use of biodegradable filter paper further enhances its environmental credentials.

3. User-Friendly Interface The machine is equipped with a state-of-the-art digital control system that simplifies operations. Operators can easily adjust settings, monitor production, and perform troubleshooting with ease. This user-friendly interface minimizes the learning curve for new staff, enhancing overall productivity.

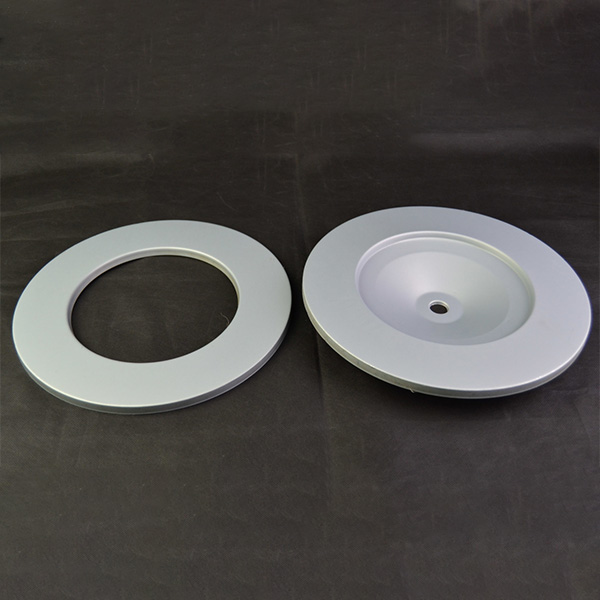

4. Versatility The PLGT-600N can produce filter paper for various applications, including but not limited to, air filters, oil filters, and liquid filters. Its adaptability makes it an invaluable asset for manufacturers looking to diversify their product offerings without investing in multiple machines.

plgt-600n full-auto rotary eco filter paper pleating production line exporter

5. Durability and Reliability Crafted from high-quality materials, the PLGT-600N is built to withstand the rigors of continuous operation. Its robust design ensures longevity and reliability, which is imperative for manufacturers who rely on consistent output.

Benefits to Manufacturers

Implementing the PLGT-600N in manufacturing facilities offers significant advantages

- Cost Efficiency Automation reduces labor costs and enhances production efficiency, allowing for greater cost-effectiveness. Manufacturers can allocate their resources more strategically, focusing on innovation and market expansion rather than on labor-intensive processes.

- Quality Consistency With precise control over the pleating process, the PLGT-600N ensures that each filter paper product meets high standards of quality and performance. This consistency is crucial in maintaining customer satisfaction and trust.

- Market Competitiveness The ability to produce high volumes of quality filter paper quickly positions manufacturers to respond to market demands promptly. This agility gives businesses a competitive edge in a rapidly evolving marketplace.

Conclusion

The PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line is a transformative tool for filter paper manufacturers aiming to enhance production efficiency while adhering to eco-friendly practices. As industries increasingly prioritize sustainability in their operations, the demand for innovative solutions like the PLGT-600N will continue to rise. By investing in such technology, manufacturers not only improve their operational capabilities but also contribute to a more sustainable future.

In conclusion, the PLGT-600N stands at the forefront of the filter paper production industry, merging cutting-edge technology with environmental stewardship. It epitomizes how modern manufacturing can evolve to meet both economic and ecological challenges, making it a valuable addition to any production line.

-

Premium Coffee Filter Rolling Paper: Fine Mesh for Smooth DIY

NewsAug.27,2025

-

Advanced PP Spun Filter Cartridge Making Machine - Precision & Speed

NewsAug.26,2025

-

Active Carbon Air Filter for Air Purifier: Odor & VOC Control

NewsAug.25,2025

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025