Sep . 02, 2024 10:29 Back to list

High-Quality Spin-On Oil Filter Production Line

The Production Line for Spin-On Oil Filters A Comprehensive Overview

In the automotive and machinery industries, oil filters play a crucial role in maintaining engine performance and longevity. Among the various types of oil filters, spin-on oil filters are particularly popular due to their ease of installation and efficiency. The production line for spin-on oil filters is a sophisticated assembly of machinery and technology designed to create high-quality filters that meet stringent industry standards.

The production process begins with the sourcing of raw materials, primarily metal for the filter housing and advanced filter media. High-grade metal is essential, as it must withstand high pressure and temperature without deforming. The filter media, typically made from a combination of cellulose, synthetic fibers, and other materials, is engineered to effectively trap contaminants while allowing oil to flow smoothly.

Once the materials are gathered, the first step in the production line involves stamping the metal sheets into the desired shapes for the filter housing. This process uses precision machining techniques to ensure consistency and accuracy. After stamping, the metal components are subjected to a series of treatments to enhance their durability and resistance to corrosion. This may include galvanizing or coating with special paints.

spin-on oil filter production line product

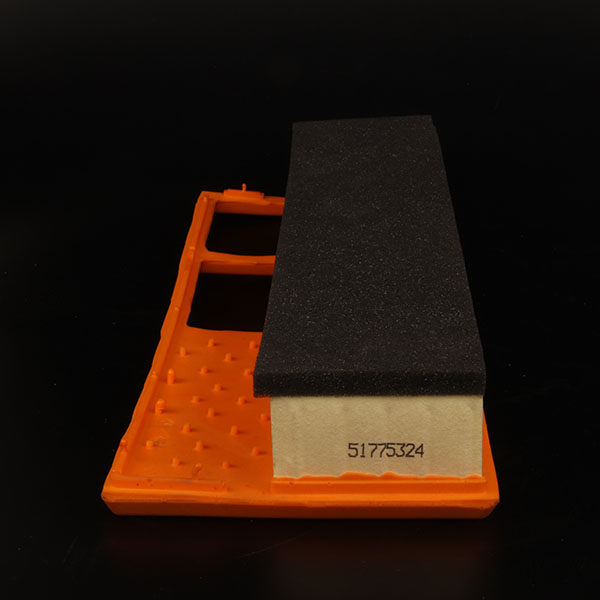

Following the preparation of the housing, the next phase involves the assembly of the filter elements. The filter media is carefully cut and pleated to maximize surface area, ensuring optimal filtration efficiency. This pleated media is placed inside the metal housing, along with a rubber or silicone O-ring that provides a tight seal, preventing leaks.

Automation plays a vital role in the production line, with robotic arms and conveyor belts facilitating the seamless movement and assembly of components. Quality control checks are integrated at various stages of the production process. These checks involve inspecting the filters for structural integrity, filtration performance, and adherence to safety standards. Advanced sensors and testing machines are employed to ensure that each filter is reliable and free of defects.

Once the filters pass inspection, they are packaged for distribution. Packaging not only protects the filters during transport but also provides vital information for consumers, including installation instructions and specifications.

In conclusion, the production line for spin-on oil filters is a finely-tuned process that combines advanced technology and skilled labor. From sourcing raw materials to quality control measures, each step is critical in ensuring that the final product meets the demands of modern engines. As the automotive industry continues to evolve, so too will the technologies and methods used in the production of oil filters, ensuring that engines remain clean and efficient.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025