Nov . 28, 2024 13:10 Back to list

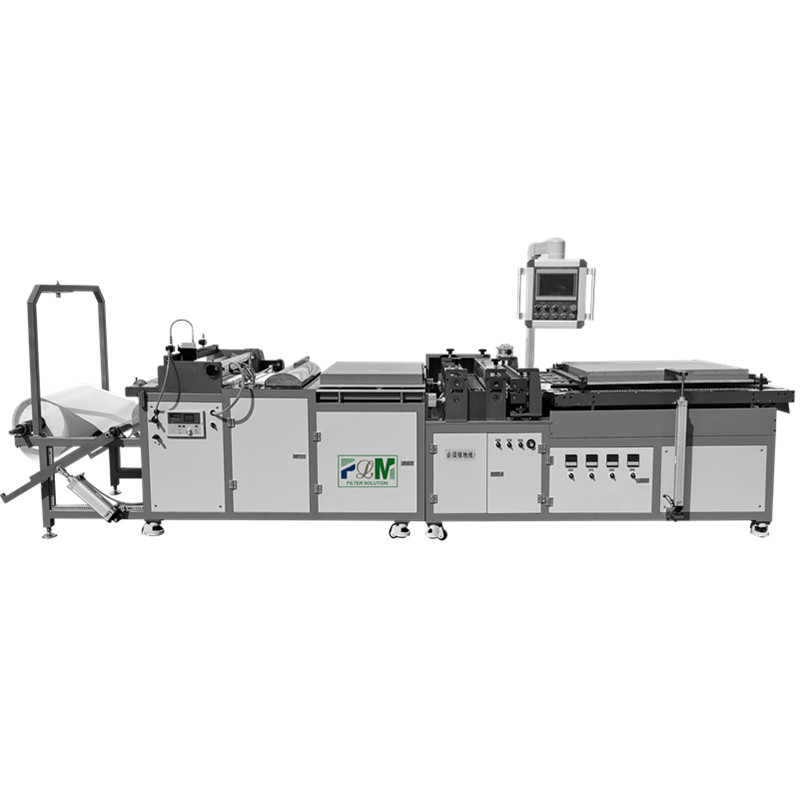

Full Automatic Ultrasonic Welding Machine for Best PLCs with Efficient Filter Element

The Best PLCs in Full-Auto Filter Element Ultrasonic Welding Machines

In the world of industrial manufacturing, the demand for precision and efficiency has never been greater. With the advent of advanced automation technologies, businesses are constantly seeking ways to optimize their production processes. One area where this is particularly evident is in the field of ultrasonic welding, especially when it comes to the manufacturing of filter elements. Here, we discuss the benefits and configurations of using the best programmable logic controllers (PLCs) in full-auto ultrasonic welding machines.

Ultrasonic welding is a technique that utilizes high-frequency ultrasonic vibrations to join materials together. This method is particularly effective for thermoplastics and composites, making it ideal for producing filter elements used in oil, air, and water filtration systems. The precision of ultrasonic welding ensures that these components are joined with integrity and longevity, essential attributes for products exposed to various stresses and environmental conditions.

To achieve optimal performance in ultrasonic welding, the integration of a high-quality PLC is critical. PLCs serve as the brains of the welding machine, controlling the entire process from initial setup to final production. They ensure that all machine elements operate harmoniously, leading to consistent product quality and reduced cycle times.

One of the primary advantages of employing advanced PLCs in ultrasonic welding machines is their ability to automate complex processes. Modern PLCs come equipped with user-friendly programming interfaces that allow operators to set specific parameters for the welding process easily. These parameters include frequency, amplitude, pressure, and time, all of which significantly influence the quality of the weld. By automating these settings, manufacturers can ensure that each weld meets the established quality standards without the risk of human error.

Additionally, the best PLCs provide real-time monitoring and data logging capabilities. This feature not only enhances the machine's operational efficiency but also allows for predictive maintenance, reducing downtime. By collecting data on machine performance and welding parameters, operators can identify trends and make informed decisions about maintenance schedules, ultimately prolonging the life of the equipment.

best plcs-1a full-auto filter element ultrasonic welding machine

Moreover, advanced PLCs support connectivity with other automation elements in a production line. This connectivity enables seamless integration with other equipment such as conveyors, inspection systems, and packing machinery. A fully automated manufacturing line reduces labor costs and increases production speed while ensuring a high level of product quality.

When selecting a PLC for an ultrasonic welding machine, it is crucial to consider the type of environment it will operate in. Many high-performance PLCs are designed to withstand harsh industrial conditions, including dust, temperature fluctuations, and humidity. Choosing a rugged and reliable PLC ensures uninterrupted production and enhances overall system robustness.

Another essential factor to consider is scalability. As businesses grow, their production needs may change. The best PLCs offer scalability options that allow manufacturers to expand their operations without significant overhauls to existing systems. This flexibility makes it easier to adapt to new production demands and innovations in welding technology.

Furthermore, leading PLC manufacturers often provide extensive technical support and resources, including training for operators and maintenance personnel. This support ensures that companies can maximize the capabilities of their ultrasonic welding machines, leading to improved efficiency and reduced operational costs.

In conclusion, the integration of the best PLCs in full-auto ultrasonic welding machines is vital for maximizing production efficiency and ensuring high-quality filter elements. These advanced controls not only automate complex processes but also enhance monitoring and connectivity within production lines. As industries continue to embrace automation, investing in superior PLC technology will undoubtedly provide a competitive edge, enabling manufacturers to meet the ever-increasing demands of the market while maintaining exceptional quality standards. Whether in automotive, aerospace, or consumer goods, the effective use of PLCs in ultrasonic welding is set to shape the future of manufacturing, fostering innovation and sustainability.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025