Dec . 03, 2024 16:32 Back to list

nylon filter mesh pricelist

Understanding the Pricing of Nylon Filter Mesh A Comprehensive Guide

Nylon filter mesh is an essential component in various industries, known for its strength, versatility, and excellent filtration properties. It is widely used in applications such as water treatment, food and beverage processing, pharmaceuticals, and even in household items. As the demand for nylon filter mesh continues to grow, understanding the pricing factors can help businesses and consumers make informed purchasing decisions.

What is Nylon Filter Mesh?

Nylon filter mesh is made from nylon fabric, a synthetic polymer known for its durability and resistance to chemicals, temperature, and abrasion. It usually comes in a variety of mesh sizes, which refers to the number of openings per linear inch. The size of the mesh determines the filtration level, making it crucial to choose the right type for specific applications.

For example, a finer mesh might be used for filtering out particulate matter in beverages, while a coarser mesh can be suitable for straining seeds or larger debris in industrial applications. The mesh is available in different thicknesses and strengths, impacting both its functionality and price.

Factors Influencing Price

Understanding the price of nylon filter mesh requires consideration of multiple factors

1. Mesh Size and Type The specific mesh size you require plays a significant role in pricing. Finer meshes often demand a higher price due to the complexity involved in their production. Additionally, specialized types of nylon mesh, such as those with unique coatings or treatments, can also command higher prices.

2. Material Quality The quality of nylon used in the fabrication of the mesh significantly affects its price. Higher-quality nylon will generally offer better durability and resistance to wear and tear, which can justify a higher price point.

nylon filter mesh pricelist

3. Manufacturing Processes The production process of nylon filter mesh also impacts its cost. Techniques such as weaving, extrusion, and coating can vary in complexity and energy consumption, influencing the final price. Manufacturers investing in advanced technology or eco-friendly processes may pass on some of those costs to consumers.

4. Custom Specifications Many businesses require custom solutions tailored to their specific needs. Custom cut sizes, colors, or mesh patterns will often come at a premium compared to standard options.

5. Quantity Purchased Bulk purchases often come with discounts that can significantly lower the per-unit cost of nylon filter mesh. Businesses that anticipate high usage might consider buying in larger quantities to take advantage of these savings.

6. Supplier Reputation Established suppliers with a reputation for quality and reliability may charge higher prices, but this could ensure better performance and service. It’s important to balance quality and price when selecting a supplier.

Typical Price Ranges

While prices can vary widely based on the factors mentioned, a typical nylon filter mesh may range from $0.50 to $5.00 per square foot. For specialized or high-performance options, costs can escalate to $10.00 or more per square foot. It’s crucial to obtain quotes from multiple suppliers to find competitive pricing while ensuring that the mesh meets your specific filtration requirements.

Conclusion

The pricing of nylon filter mesh is influenced by a multitude of factors, including mesh size, material quality, manufacturing processes, customization, purchase quantity, and supplier reputation. As industries continue to innovate and demand specialized filtration solutions, staying informed about these factors will enable businesses and consumers to make well-informed decisions regarding their purchases.

In an era where efficiency and quality are paramount, selecting the right nylon filter mesh not only impacts operational processes but also ensures a level of reliability and effectiveness in filtration applications. By categorizing needs, evaluating options, and understanding pricing structures, stakeholders in various sectors can optimize their filtering systems, ultimately leading to enhanced productivity and satisfaction.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

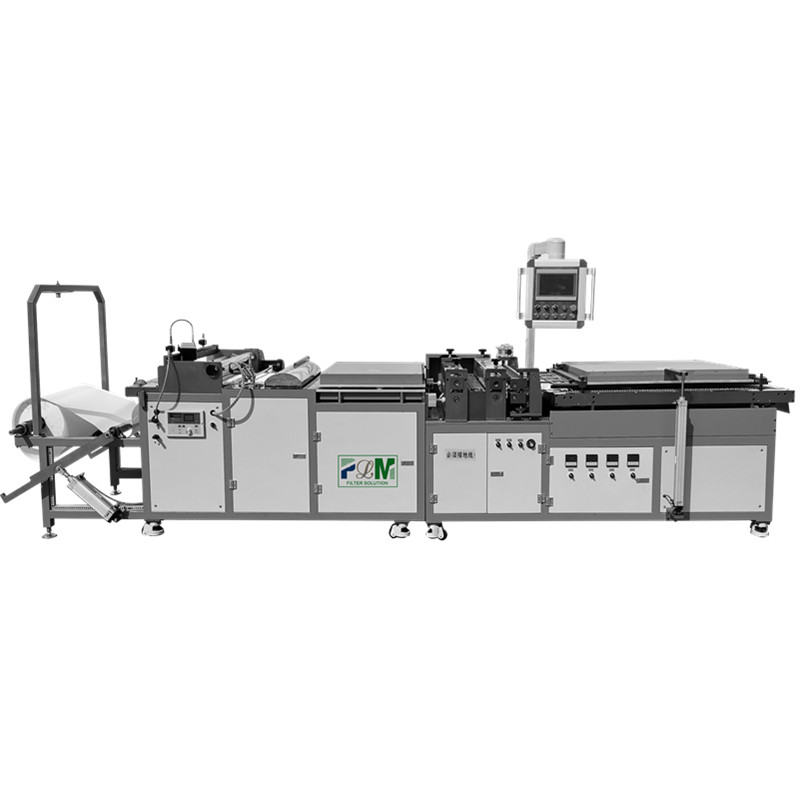

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025