Dec . 11, 2024 19:21 Back to list

pllw-600/1000/1250 expanded mesh making machine manufacturer

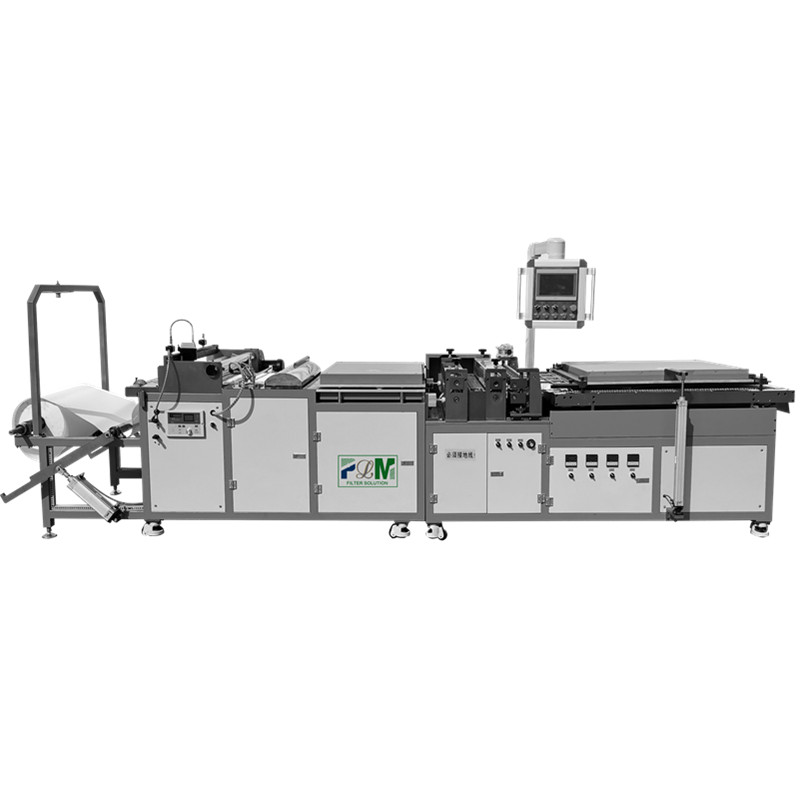

Understanding the Importance of the PLLW-600/1000/1250 Expanded Mesh Making Machine

In the world of manufacturing, especially in construction and industrial sectors, the demand for high-quality materials is ever-increasing. One such material that is crucial for various applications is expanded metal mesh. This mesh is widely used for security fencing, architectural panels, grills, and other applications. The PLLW-600/1000/1250 expanded mesh making machine has emerged as a pivotal tool for manufacturers looking to meet this high demand efficiently.

What is Expanded Metal Mesh?

Expanded metal mesh is a versatile material created from a single piece of metal sheet. The sheet is slit and stretched to create a diamond-shaped pattern, resulting in a lightweight yet strong mesh. This unique manufacturing process increases the surface area and enhances durability, making it ideal for a range of applications from construction to transportation.

Features of the PLLW-600/1000/1250 Expanded Mesh Making Machine

The PLLW series of expanded mesh making machines (600, 1000, and 1250) are designed to cater to various production capacities and requirements. Each model is equipped with several features that enhance its performance

1. Robust Construction Made from high-quality materials, these machines ensure durability and longevity, capable of withstanding rigorous manufacturing conditions.

2. High Efficiency The machines are designed to operate at high speeds, allowing manufacturers to produce large volumes of expanded mesh in shorter periods, thereby increasing productivity.

4. User-Friendly Interface Equipped with a modern control system, the operation of these machines is straightforward and intuitive, requiring minimal training for operators.

pllw-600/1000/1250 expanded mesh making machine manufacturer

5. Safety Features Built-in safety systems ensure that operators work in a protected environment, reducing the risks of accidents during operation.

Applications of Expanded Metal Mesh

The expanded metal mesh produced by the PLLW-600/1000/1250 machines has a myriad of applications

- Construction Industry Used for walkways, safety barriers, and reinforcing materials in concrete work. - Filtration Ideal for filter media in various industries due to its ability to retain particles while allowing air flow. - Architectural Design Expanded metal adds aesthetic value as cladding and facades in modern architecture. - Transportation Often used in vehicles for grilles and safety enhancements.

The Manufacturing Process

The manufacturing process of expanded metal begins with feeding a metal sheet into the PLLW machine. It undergoes several automated steps, including slitting and stretching. Following this, the mesh is cut to the desired specifications and subjected to quality checks to ensure it meets industry standards. This streamlined process reduces waste and maximizes efficiency.

Market Trends and Demand

The demand for expanded metal mesh continues to grow, driven by the expansion of construction projects worldwide and an increased focus on sustainable materials. Manufacturers equipped with machines like the PLLW-600/1000/1250 can meet these demands effectively. Additionally, as building codes evolve to require more durable and secure materials, the need for quality expanded metal is more pronounced than ever.

Conclusion

In conclusion, the PLLW-600/1000/1250 expanded mesh making machine represents a significant advancement in manufacturing technology. Its role in producing high-quality expanded metal mesh cannot be overstated as it caters to the growing needs of various industries. With its robust features and efficiency, this machine not only improves production capacity but also enhances the quality of the final products. As we move forward in an era of rapid industrialization and innovation, investing in such machinery is essential for manufacturers aiming to remain competitive in a challenging market. Embracing technological advancements will undoubtedly lead to better quality products and increased customer satisfaction, paving the way for business growth and success.

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025