Nov . 28, 2024 07:08 Back to list

Air Filtering Material Production and Supplier Industry Insights and Trends

Exploring Air Filter Material Manufacturers The Heart of Clean Air Technology

In the modern world, where air quality has become a pressing concern, air filter materials are pivotal to ensuring that our environment remains breathable and healthy. The manufacturers of these materials play a crucial role in the air purification industry, providing innovative solutions and products that address the diverse needs of residential, commercial, and industrial applications.

Understanding Air Filter Materials

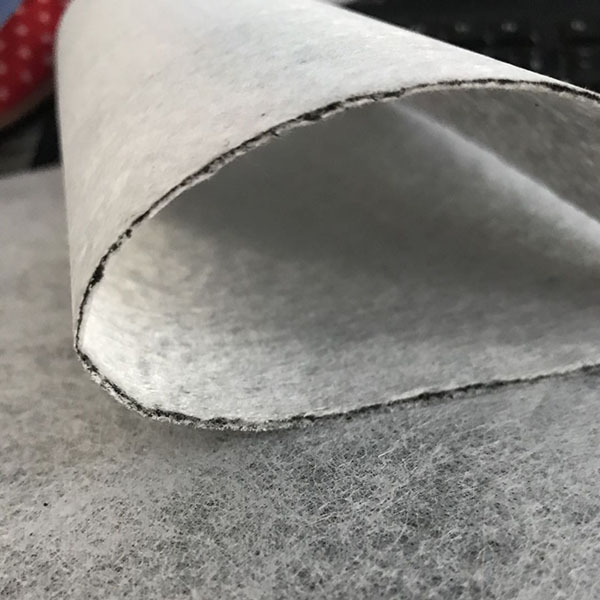

Air filters are designed to trap airborne particles, allergens, dust, pollen, and pollutants. The efficiency and effectiveness of an air filter largely depend on the type of materials used in its construction. Common materials include fiberglass, pleated polyester, activated carbon, HEPA (High-Efficiency Particulate Air), and electrostatic fibers. Each type offers unique benefits tailored to specific filtering needs.

Fiberglass Filters Traditionally, fiberglass filters are among the most inexpensive options. They are designed for larger particles and offer minimal resistance to airflow, making them suitable for general purpose use. However, their ability to filter fine particulate matter is limited.

Pleated Polyester Filters These are an upgrade from fiberglass filters. The pleated design increases the surface area, allowing for better dust holding capacity and improved filtration efficiency. They are ideal for both residential HVAC systems and commercial installations.

Activated Carbon Filters Not only do these filters physically trap particles, but they also have the unique ability to adsorb odors and gaseous pollutants. This makes them popular for use in environments where VOCs (Volatile Organic Compounds) are a concern, such as kitchens and industrial spaces.

HEPA Filters Regarded as the gold standard in air filtration, HEPA filters can capture at least 99.97% of particles that are 0.3 microns in diameter. Manufacturers of HEPA filters often focus on rigorous testing and certification processes to ensure their products meet strict international standards.

Electrostatic Filters These filters use static electricity to attract and trap particles. They can be washed and reused, making them a sustainable choice in air filtration.

air filter material manufacturer

The Role of Manufacturers

Manufacturers of air filter materials play a crucial role in the supply chain of air purification technologies. They are responsible for the design, development, and production of filter materials that meet specific regulatory and performance standards. The process often involves research and development to innovate new materials and improve existing ones. This can include enhancing the filtration efficiency, increasing the lifespan of the filters, and developing more eco-friendly options.

Additionally, manufacturers must ensure that their processes are sustainable and that their products comply with health and environmental regulations. This commitment to sustainability is becoming increasingly important to consumers, prompting manufacturers to adopt greener practices and materials.

Innovations in Air Filter Materials

The industry is witnessing a wave of innovations aimed at improving air quality. For instance, the integration of nanotechnology in filter materials has led to the development of filters that can trap even the smallest particulate matter, including bacteria and viruses. Moreover, smart filters with embedded sensors are being developed to monitor air quality in real-time, providing users with valuable data about their environment.

Additionally, many manufacturers are focusing on creating filters that are less harmful to the environment. Biodegradable materials and sustainable manufacturing processes are becoming more commonplace, reflecting a growing trend towards environmental responsibility in the industry.

Conclusion

In conclusion, air filter material manufacturers are at the forefront of protecting public health and enhancing indoor air quality. With the increasing awareness of air pollution and its impacts on health, the demand for high-quality air filtration materials will continue to grow. As manufacturers innovate and embrace sustainable practices, they not only contribute to cleaner air but also help foster a healthier planet for future generations. The synergy between advanced technology and responsible manufacturing will undoubtedly shape the future of air filtration. As consumers become more conscious about air quality, the role of these manufacturers will remain critical in the journey towards achieving cleaner air for all.

-

OEM Truck Air Filters Machine Production Line - Custom Solutions

NewsMay.18,2025

-

Toyota Air Filter Producing Machine High-Efficiency Manufacturing Solutions

NewsMay.18,2025

-

Affordable Truck Air Filters High Quality & Low Cost

NewsMay.18,2025

-

Spiral Filter Core Making Machine High-Precision & Automated Solutions

NewsMay.17,2025

-

Buy PL-CQ1 Toyota Filter Cutting Machine Precision & Efficient Design

NewsMay.17,2025

-

Wholesale PLCY-200 Fuel Filter Tester Precision Testing & Bulk Deals

NewsMay.16,2025