Jan . 02, 2025 19:17 Back to list

plxn-50 oil filter performance tester companies

The Importance of Oil Filter Performance Testing in Automotive Industries

In the highly competitive automotive industry, ensuring the reliability and efficiency of engine components is paramount. One critical component that significantly influences engine performance is the oil filter. The oil filter serves to cleanse the engine oil, removing contaminants and particles that can cause wear and tear over time. With the increasing complexity of modern engines, the efficacy of oil filters has never been more crucial. This is where the importance of oil filter performance testing comes into play, as demonstrated by companies such as those producing PLXN-50% oil filter performance testers.

Understanding Oil Filter Performance Testing

Oil filter performance testing involves evaluating various qualities of oil filters, including their filtration efficiency, capacity, and the pressure differential during operation. These tests help manufacturers ensure that their products meet stringent industry standards and can withstand the demands placed on them in real-world conditions. Performance testers like the PLXN-50% are designed to provide accurate measurements and insights into how well an oil filter performs under various scenarios.

Key Features of PLXN-50% Oil Filter Performance Testers

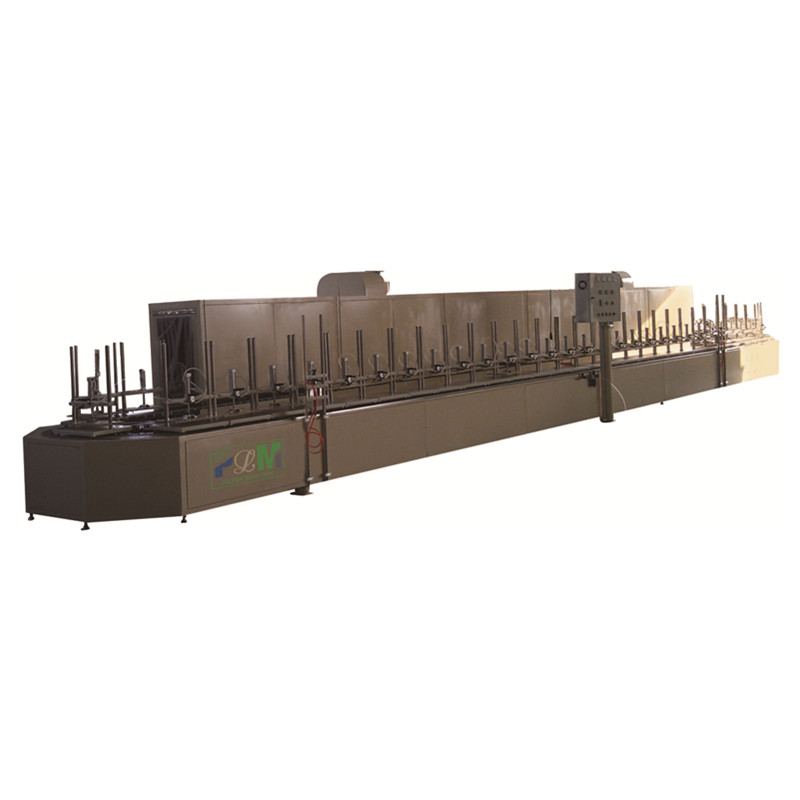

Companies engaged in the production and testing of oil filters utilize advanced equipment like the PLXN-50% oil filter performance tester to carry out comprehensive evaluations. This specific tester is engineered with cutting-edge technology capable of simulating real-life conditions in controlled environments.

1. Filtration Efficiency One of the primary metrics evaluated is the filtration efficiency, often expressed as a percentage. A high-performance oil filter must be able to eliminate particles of varying sizes, ensuring that the engine oil remains clean and effective at lubricating engine components.

2. Dirt Holding Capacity This refers to how much contamination a filter can hold before it becomes ineffective. Testers like PLXN-50% measure the point at which an oil filter reaches saturation and can no longer perform its function, a critical factor for maintenance schedules and vehicle longevity.

plxn-50 oil filter performance tester companies

3. Pressure Differential As filters accumulate dirt, a pressure differential occurs between the inlet and outlet sides. High-quality testing apparatus measures this differential to ensure filters can maintain optimal flow rates without causing undue stress on the engine.

The Role of Testing Companies

Numerous companies are dedicated to producing oil filter performance testers and conducting tests on various oil filter models. They play an essential role in the automotive supply chain by helping manufacturers refine their products and maintain compliance with regulatory standards. These testing facilities contribute to research and development processes, enabling innovation in filter design and materials that enhance longevity and performance.

The Benefits of Efficient Oil Filters

The advantages of robust, high-efficiency oil filters extend beyond mere engine performance. Improved filtration leads to cleaner engine oil, which in turn reduces emissions and enhances fuel economy. In an era where automotive manufacturers face increasing scrutiny regarding environmental impacts, these benefits align with corporate responsibility initiatives and stricter regulations.

Conclusion

As vehicles evolve, so too do the technologies that support them. The importance of oil filter performance testing, particularly through advanced equipment like the PLXN-50% oil filter performance tester, cannot be overstated. It assures manufacturers that their products will deliver the reliability, efficiency, and durability necessary for modern engines. In partnering with reputable testing companies, automotive manufacturers can create superior oil filters that not only protect engines but also contribute positively to environmental sustainability efforts. As the industry progresses, continued investment in testing technology will undoubtedly yield significant dividends in performance and efficiency for the sophisticated vehicles of tomorrow.

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Production

NewsAug.18,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man Automotive Parts Trading Co., Ltd | Adjustable Gluing Parameters, Automated Precision

NewsAug.18,2025

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Engineering&Efficiency

NewsAug.18,2025

-

Active Carbon Air Filter for Purifier: Superior Air Quality & Odor Removal

NewsAug.18,2025

-

PLAB-6 Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Filtering

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.17,2025