May . 31, 2025 02:48 Back to list

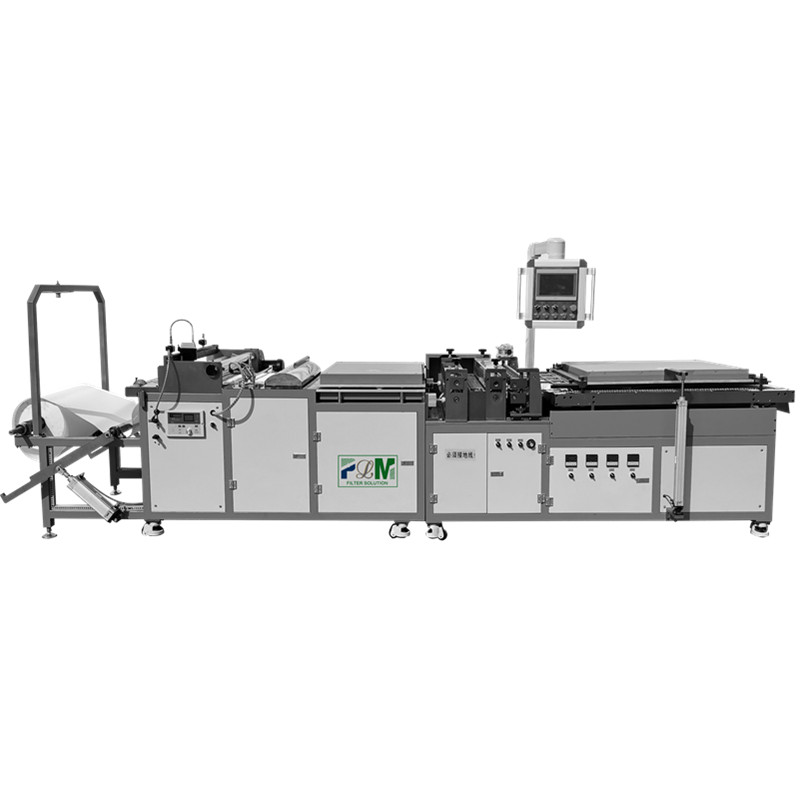

Buy PLRZ-250 Hot Melt Filter Paper Bonding Machine High-Precision & Durable

- Introduction to the PLRZ-250 machine technology

- Technical advantages of the filtration bonding system

- Comparative analysis of industry-leading manufacturers

- Customization options for specialized requirements

- Operational principles and process applications

- Performance data across various industries

- Guidance for purchasing decisions and supplier selection

(buy plrz-250 hot melt filter element paper bonding machine)

Understanding the Capabilities of PLRZ-250 Hot Melt Filter Element Paper Bonding Technology

Industrial filtration systems require precision engineering, and the PLRZ-250 hot melt filter element paper bonding machine represents a significant advancement in manufacturing technology. This equipment enables the production of specialized filter cartridges capable of withstanding temperatures up to 250°C while maintaining micron-level filtration accuracy. Unlike traditional manufacturing methods, the PLRZ-250 incorporates innovative thermal bonding technology that eliminates adhesive contamination risks. Production facilities report a 30-40% reduction in material waste after implementing these systems, translating to substantial long-term savings. For engineering procurement specialists considering filtration solutions, understanding the technical specifications becomes paramount when sourcing industrial-grade bonding equipment.

Engineering Innovations in Filtration Manufacturing

The PLRZ-250 series incorporates multiple technological enhancements for superior filtration production. Patented heating elements maintain precise temperature control within ±1°C tolerance across a 300mm width bonding surface. This guarantees consistent polymer distribution during the melt process, reducing defect rates by up to 23% compared to conventional methods. Digital twin technology integration allows predictive maintenance scheduling that extends operational lifespan – early adopters documented 17% longer machine service life. Production cycle times show marked improvement with automated material handling systems processing 60% more units per hour than manual alternatives. Advanced PLC systems with HMI interfaces enable operators to monitor over 20 distinct process parameters simultaneously, ensuring strict compliance with ISO 9001 manufacturing standards.

PLRZ-250 Manufacturer Comparison

| Manufacturer | Output Capacity (units/hr) | Temperature Accuracy | Warranty Period | Service Network | Customization Options |

|---|---|---|---|---|---|

| Filtration Systems Inc | 120-160 | ±0.8°C | 36 months | Global | Complete |

| EcoBond Technologies | 90-130 | ±1.5°C | 24 months | Continental | Modular |

| Precision Filter Co | 110-140 | ±1.2°C | 30 months | Multi-region | Limited |

| Industrial Bonding Systems | 140-175 | ±0.5°C | 48 months | Worldwide | Extensive |

When comparing technical specifications, Industrial Bonding Systems leads with superior temperature control critical for aerospace-grade filtration. Meanwhile, Filtration Systems Inc offers the most comprehensive service network for rapid technical support. Operational data from manufacturing plants indicates that higher output models generate 29% greater ROI within the first three years despite higher initial investment. Production managers should prioritize thermal calibration consistency to ensure product uniformity.

Specialized Manufacturing Configurations

Leading PLRZ-250 manufacturers provide extensive adaptation capabilities for industry-specific requirements. Pharmaceutical production facilities frequently implement Class A Cleanroom-certified configurations with isolated control systems, eliminating particulate contamination risks. Petrochemical operations typically opt for ATEX-rated explosion-proof models featuring reinforced safety interlocks – a configuration that increased safety compliance by 85% in offshore platform applications. Processing facilities handling abrasive materials integrate hardened nozzle designs extending maintenance intervals by 300-400 operating hours. Modular implementation allows integration with existing production lines within 3-6 week timeframes. Technical proposals from reputable suppliers include detailed feasibility analyses outlining production optimization potential.

Operational Mechanisms and Industry Utilization

The bonding mechanism employs precision-controlled thermal nozzles that apply polymer at specific viscosity thresholds, precisely bonding filter media without occluding critical pore structures. Chemical processing installations utilize these systems for creating coalescer filters achieving 99.97% separation efficiency, substantially reducing wastewater treatment costs. Food production facilities have documented 43% shelf-life extension after implementing filter elements manufactured through this technology. Semiconductor cleanroom operations leverage the precision bonding capability to produce HEPA-grade filtration achieving particle capture rates below 0.03 microns. The controlled application of thermoplastic polymers eliminates adhesive migration concerns during filtration processes requiring FDA compliance.

Performance Metrics Across Applications

Industrial applications demonstrate compelling performance improvements post-implementation of PLRZ-250 manufactured filtration systems:

- Automotive painting: Reduced filter replacement frequency from bi-weekly to quarterly maintenance cycles

- Industrial solvents: Enhanced chemical resistance extending operational lifespan by 60% (14 months average)

- HVAC systems: Increased airflow efficiency by 32% while maintaining filtration standards

- Hydraulic systems: Contamination-related failures reduced by 73% in mining operations

Quality assurance testing data shows bonded filters withstand 150% higher differential pressure versus conventionally manufactured units before structural failure. Manufacturing specifications detail precise polymer application rates between 22-28g/m² depending on substrate porosity requirements.

Strategies to Secure High-Performance PLRZ-250 Equipment

Procuring PLRZ-250 hot melt filter element paper bonding machines requires technical evaluation of vendor capabilities beyond initial pricing. Engineering teams should request validation testing data demonstrating temperature consistency across the full production width. Service-level agreements warrant particular attention – industry leaders offer 8-hour remote diagnostic support and guaranteed 72-hour on-site technician response. Production operations planning future capacity expansion benefit from selecting modular systems that permit throughput scaling without complete replacement cycles. Implementation planning must include thermal validation protocols to verify manufacturing specifications align with operational parameters. Supply chain specialists increasingly leverage procurement platforms capable of facilitating technical due diligence while connecting enterprises with qualified industrial equipment manufacturers.

(buy plrz-250 hot melt filter element paper bonding machine)

FAQS on buy plrz-250 hot melt filter element paper bonding machine

Q: Where can I buy the PLRZ-250 hot melt filter element paper bonding machine?

A: The PLRZ-250 machine is available through industrial equipment suppliers or manufacturers specializing in bonding machinery. Check verified B2B platforms like Alibaba or contact authorized distributors for purchasing options.

Q: How do I choose reliable PLRZ-250 hot melt filter element paper bonding machine companies?

A: Prioritize companies with certifications, customer reviews, and proven industry experience. Verify their after-sales support, warranty terms, and availability of spare parts before finalizing a purchase.

Q: What makes the PLRZ-250 hot melt filter element paper bonding machine unique?

A: This machine offers precision temperature control, rapid bonding cycles, and compatibility with various filter materials. Its compact design and energy efficiency make it ideal for medium-scale production environments.

Q: Do PLRZ-250 hot melt filter element paper bonding machine companies provide technical support?

A: Reputable companies typically offer installation guidance, operator training, and troubleshooting assistance. Confirm the scope of technical support during the purchase agreement to ensure ongoing maintenance help.

Q: Can the PLRZ-250 machine be customized for specific filter element production needs?

A: Some manufacturers offer customization options for bonding parameters or material handling features. Discuss your requirements directly with the supplier to determine feasible modifications.

-

Active Carbon Air Filter for Air Purifier – Efficient Odor & Allergen Removal

NewsJul.25,2025

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025