Dec . 03, 2024 18:23 Back to list

Leading Companies in Pocket Air Filter Fabric Materials Industry

The Role of Fabric in Pocket Air Filter Materials An Industry Overview

In today's world, where air quality is becoming increasingly critical, pocket air filters play a vital role in ensuring healthier indoor environments. The materials used in these filters are essential for their performance, and fabric is one of the key components that determine the efficiency and functionality of pocket air filters. This article explores the significance of fabric for pocket air filter materials and highlights the leading companies in this sector.

Understanding Pocket Air Filters

Pocket air filters are widely used in HVAC systems, commercial buildings, and residential environments to trap airborne particles and maintain air quality. Unlike flat panel filters, pocket filters have multiple fabric pockets that increase their filtration surface area, allowing for greater dust and particulate capture. This extended surface area enhances the filter’s efficiency and lifespan, making it an economical choice for many applications.

The Importance of Filter Fabrics

Fabric is at the heart of pocket air filters. The type of fabric used influences several key factors

1. Filtration Efficiency The fabric material must be capable of capturing a wide range of particles, including dust, pollen, mold spores, and even allergens. Synthetic fabrics like polyester, polypropylene, and fiberglass are commonly used for their excellent filtration properties.

2. Airflow Resistance While efficient filtration is crucial, it’s equally important that the fabric allows for unobstructed airflow. This balance ensures that the HVAC system operates efficiently without excessive strain.

3. Durability The environment where air filters operate can be quite harsh, subjecting them to moisture and varying temperatures. Fabrics must be durable enough to withstand these conditions without degrading or losing effectiveness over time.

4. Maintenance and Replacement The type of fabric influences how often the filter needs to be replaced or cleaned. Some materials are designed for longer life spans, reducing maintenance frequency.

fabric for pocket air filter material companies

Leading Companies in Filter Fabric Manufacturing

Several companies are notable for their contributions to the manufacture of fabrics used in pocket air filters

1. Ahlstrom-Munksjö Renowned for its high-performance filtration materials, Ahlstrom-Munksjö produces a variety of nonwoven fabrics that are ideal for air filtration applications. Their emphasis on sustainability and innovation sets them apart, offering eco-friendly alternatives without compromising performance.

2. Morris Products Specializing in a range of HVAC products, Morris Products offers specialized filter fabrics designed for various filter types, including pocket air filters. Their dedication to quality ensures that their fabrics meet stringent standards, delivering reliable performance.

3. DuPont A pioneer in materials science, DuPont produces a range of filtration fabrics under the brand name Nomex® and Tyvek®. Their products are engineered for high efficiency and durability, making them a popular choice in industrial and commercial applications.

4. Gore Known for its advanced technology, Gore manufactures filtration media that provides excellent performance in demanding environments. Their air filters are designed to handle high dust loading and capture ultrafine particles, making them suitable for both residential and industrial settings.

5. 3M A major player in the materials industry, 3M offers a broad portfolio of filtration solutions, including pocket air filter materials. Their innovative technologies focus on maximizing efficiency and minimizing environmental impact.

The Future of Filter Fabrics

As concerns over air quality continue to rise, the demand for effective filtration solutions will only grow. Companies are investing in research and development to create advanced filter fabrics that not only meet regulatory standards but exceed the expectations of consumers. Innovations in nanofibers, biocompatible materials, and smart fabrics that can detect air quality levels are on the horizon, promising to further enhance the performance of pocket air filters.

In conclusion, the role of fabric in pocket air filter materials cannot be overstated. It is a critical factor that influences filtration efficiency, durability, and overall effectiveness. As the industry evolves, leading companies are at the forefront of creating innovative fabrics that help ensure clean and healthy indoor air, paving the way for future advancements in air filtration technology.

-

Premium Coffee Filter Rolling Paper: Fine Mesh for Smooth DIY

NewsAug.27,2025

-

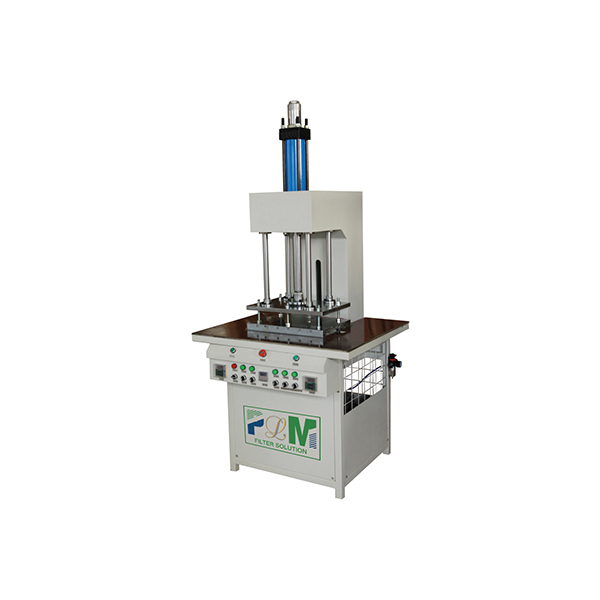

Advanced PP Spun Filter Cartridge Making Machine - Precision & Speed

NewsAug.26,2025

-

Active Carbon Air Filter for Air Purifier: Odor & VOC Control

NewsAug.25,2025

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025