Dec . 03, 2024 16:49 Back to list

High Quality Filter Paper for Optimal Pleating Performance and Durability

The Art and Science of High-Quality Filter Paper Pleating

In the realm of filtration technology, the materials used directly influence efficiency, performance, and usability. One critical component is filter paper, which plays an essential role in various applications ranging from laboratory experiments to industrial processes. Among the latest advancements in filter design is the technique of pleating high-quality filter paper, which enhances its functionality and effectiveness. This article explores the merits of pleated filter paper, the technology and methods behind the pleating process, and the applications where it excels.

Understanding Filter Paper

Filter paper is a porous material made from cellulose fibers or synthetic materials designed to separate solids from liquids or gases. Its applications are diverse, found in sectors such as environmental testing, food and beverage, pharmaceuticals, and many others. However, the performance of filter paper is often dependent on its thickness, porosity, and surface treatment. Consequently, manufacturers have sought innovative ways to improve the filter paper's surface area for better filtration efficiency, leading to the development of pleated filter paper.

The Benefits of Pleating

Pleating refers to the process of folding filter paper into an accordion-like structure, significantly increasing its surface area without enlarging its overall dimensions. This design enhances filtration efficiency in several ways

1. Increased Surface Area More pores per unit area mean that a larger volume of fluid can be processed, which increases the filter's throughput. This is particularly beneficial in high-flow applications where maximizing efficiency is crucial.

2. Improved Flow Dynamics The pleating design provides a more uniform flow path, reducing the chances of clogging and enabling stable flow rates, even with changing viscosity or particle loads.

3. Higher Dirt-Holding Capacity The additional surface area accommodates more particulate matter before the filter needs to be replaced, leading to longer operational life and reduced downtime for maintenance.

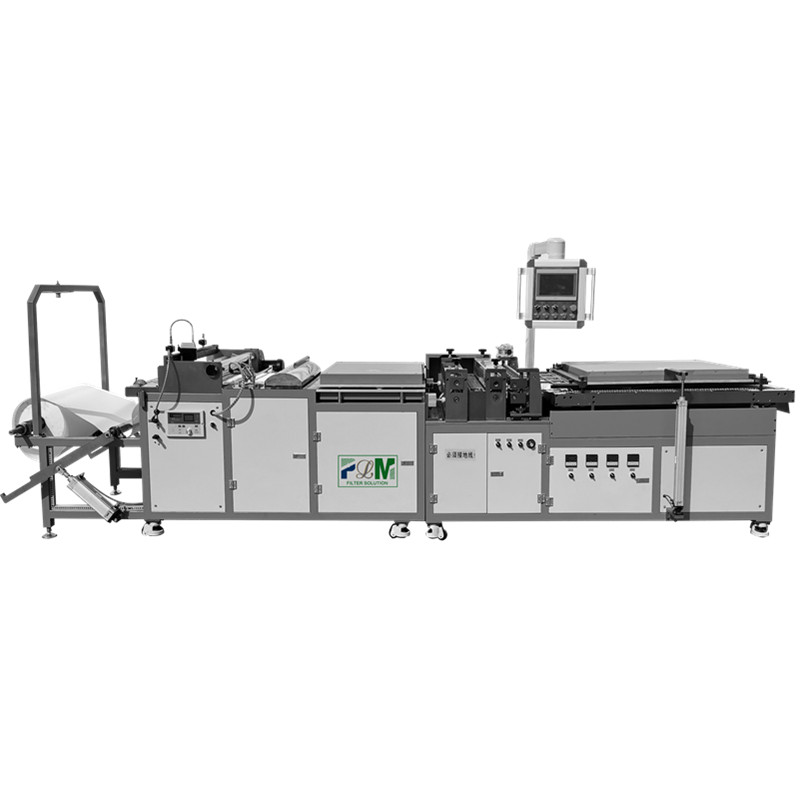

high quality filter paper pleating

4. Versatility Pleated filters can be tailored to meet specific filtration needs, such as variations in pore size and thickness, allowing them to be employed across a wide range of applications.

The Pleating Process

The process of pleating high-quality filter paper involves several steps, each crucial in ensuring the filter's performance and longevity. First, the selection of base paper is essential; high-quality cellulose or synthetic fibers are chosen for their strength and filtration properties. Following this, precision cutting and shaping of the paper are performed to ensure even folds and consistent pleats.

The pleating is achieved using specialized machinery that accurately folds and adheres the paper in an accordion structure. Adhesives that are compatible with the filter's intended use, especially in sensitive environments, must be selected carefully to avoid contaminating the filtered substances. Once pleated, the filter is often subjected to tests for filtration rate, particle retention capacity, and durability under pressure to ensure it meets the highest standards.

Applications of Pleated Filter Paper

Pleated filter paper is used across various industries, proving its versatility and efficiency. In the environmental sector, it is utilized for air and water quality testing, efficiently capturing pollutants and providing accurate data for research and regulatory compliance. In the food and beverage industry, these filters ensure product purity by removing contaminants that could compromise safety and quality. In pharmaceutical settings, pleated filter paper is crucial for sterile filtering processes, ensuring that products are free from unwanted particulate.

Conclusion

The innovation of pleating high-quality filter paper marks a significant advancement in filtration technology. By significantly enhancing surface area and optimizing flow dynamics, pleated filters offer superior performance for diverse applications. As industries continue to prioritize efficiency and sustainability, the pleating technique is likely to gain further prominence, solidifying its role in modern filtration solutions. Exploring and adopting such advancements not only improves operational outcomes but also paves the way for innovative applications in the future.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025