Sep . 16, 2024 00:47 Back to list

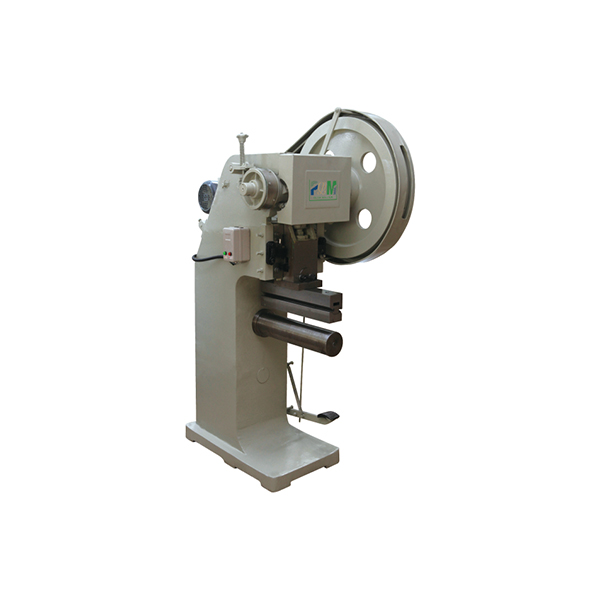

oem 2014 - car air filter making machine

The Evolution of the OEM Car Air Filter Making Machine in 2014

In 2014, the automotive industry witnessed significant advancements in manufacturing processes, particularly in the domain of car air filters. The OEM (Original Equipment Manufacturer) air filter making machines became pivotal in ensuring the production of high-quality automotive components aimed at enhancing vehicle performance and longevity. Understanding these changes involves exploring the technology, efficiency, and benefits these machines brought to the automotive sector.

Firstly, the car air filter plays a crucial role in maintaining engine performance. It prevents dirt, dust, and other contaminants from entering the engine, thereby protecting internal components and ensuring longevity. Given the increasing demands for higher performance and efficiency from consumers and regulators alike, the production of air filters needed to evolve.

The Evolution of the OEM Car Air Filter Making Machine in 2014

One notable advancement was in the machine's ability to handle a variety of materials. Modern air filter machines could work seamlessly with multiple filter media, such as paper, foam, and synthetic materials. This flexibility allowed manufacturers to cater to different vehicle models and specifications, enhancing their product offerings. Furthermore, many of these machines were equipped with intelligent control systems that enabled real-time monitoring of production processes, ensuring consistent quality and reducing waste.

oem 2014 - car air filter making machine

Additionally, the capacity for mass production introduced by these machines was revolutionary. The car industry is characterized by tight deadlines and a need for large volumes of components. OEM air filter making machines of 2014 could produce thousands of filters daily, thus supporting automotive assembly lines that required just-in-time delivery. This capability not only improved supply chain efficiency but also contributed to cost savings for automobile manufacturers.

Sustainability also played a vital role in this evolution. As environmental concerns escalated, manufacturers sought ways to produce air filters that not only enhanced vehicle performance but also minimized environmental impact. Many 2014 OEM machines began incorporating eco-friendly practices, such as using recyclable materials and energy-efficient processes. This shift not only addressed regulatory requirements but also catered to a growing consumer preference for sustainable products.

Moreover, the technological advancements made in 2014 paved the way for future innovations. The integration of smart technology, such as IoT (Internet of Things) capabilities, began to emerge, allowing manufacturers to connect machines to networks for better data collection and analysis. This capability facilitated predictive maintenance, reducing downtime and ensuring that the machines operated at peak efficiency.

In conclusion, the OEM car air filter making machines of 2014 represented a fusion of technology, efficiency, and sustainability in automotive manufacturing. These machines not only revolutionized the way air filters were produced but also ensured that the automotive industry could meet the demands of a changing market. As manufacturers embraced these innovations, the path was paved for further advancements that would continue to shape the automotive landscape in the years to come.

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025