Desemba . 01, 2024 02:37 Back to list

china truck air filter producing machine

The Importance of Air Filters in the Truck Industry and the Role of Manufacturing Machines

Air quality is a critical consideration in the automotive industry, especially for heavy-duty vehicles such as trucks. With their substantial engines and extensive usage in various environments, these vehicles require high-quality air filters to operate efficiently and sustainably. As the demand for trucks increases due to the growth of global trade and logistics, so does the need for innovative manufacturing technology, particularly focused on air filter production.

Understanding Air Filters

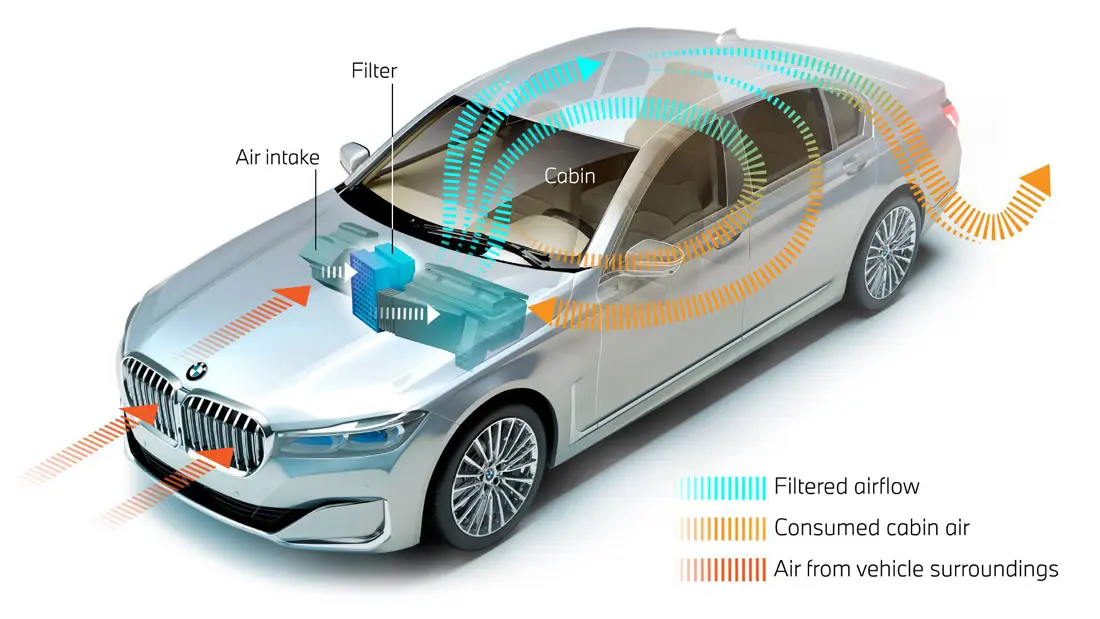

Air filters serve an essential function in truck engines by preventing harmful contaminants from entering the engine. Dust, dirt, and particles can lead to engine wear and reduced performance, making the air filter one of the crucial components for maintaining a truck's functionality. In heavy-duty applications, the ability of an air filter to maintain clean air intake is vital, not only for engine health but also for fuel efficiency and emissions control.

The Growth of the Truck Market

China has rapidly emerged as a key player in the global truck market, driven by its vast infrastructure projects and increasing urbanization. This growth has resulted in a surge in demand for various truck components, including air filters. The country's manufacturing capabilities allow for the mass production of high-quality air filters tailored to different truck models and engines.

Manufacturing Machines for Air Filters

To meet the rising demand for air filters, specialized manufacturing machines are essential. These machines are designed to produce filters efficiently and consistently, ensuring that they meet strict quality standards. The production of air filters involves several processes, including

1. Material Selection The primary materials used for air filters include synthetic fibers, paper, and foam. Each material offers different filtration characteristics, and the choice often depends on the specific requirements of the truck's operating conditions.

2. Cutting and Shaping Automated machines cut and shape the raw materials into the desired dimensions. Precision in this step is crucial to ensure that the filters fit perfectly in various truck models.

china truck air filter producing machine

3. Assembly Once the materials are cut, they are assembled into final filter products. This stage may involve gluing, stitching, or heat-sealing the layers together to create a durable filter.

4. Testing Quality control is critical in the production process. Air filters undergo rigorous testing to assess their filtration efficiency and durability. Machines equipped with advanced technology can simulate real-world conditions to ensure that each filter can effectively protect the engine.

5. Packaging After testing, the filters are packaged for distribution. Automation technology enables efficient and secure packaging, minimizing the risk of damage during transport.

Innovations in Air Filter Manufacturing

Recent advancements in manufacturing technology have significantly improved the production of air filters. The integration of automation and artificial intelligence in manufacturing processes has led to increased efficiency and reduced costs. Smart machines can optimize production schedules, minimize waste, and ensure consistent quality.

Moreover, sustainability practices are becoming increasingly important. Manufacturers are now exploring eco-friendly materials and production methods to reduce their environmental footprint. This is especially relevant in China, where regulatory pressures are rising to combat pollution and promote sustainable manufacturing practices.

The Future of Truck Air Filter Production in China

As the truck market continues to expand, the production of high-quality air filters will remain a priority for manufacturers. With ongoing investments in technology and innovation, China is poised to lead in producing air filters that meet international standards of quality and performance.

In conclusion, the air filter is a small yet critical component of a truck engine, significantly affecting performance and longevity. The manufacturing machines that produce these filters play a vital role in ensuring that trucks operate efficiently in various conditions. As technology advances and the market evolves, the importance of high-quality air filter production will only increase, making it an exciting area to watch in the coming years.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025