Septemba . 03, 2024 08:11 Back to list

filter caps product

The Role of Filter Caps in Product Development and Quality Assurance

In today’s fast-paced manufacturing landscape, the need for effective filtration solutions has become increasingly critical. Among these solutions, filter caps stand out as an essential component that ensures the quality and integrity of various products across multiple industries. From pharmaceuticals to cosmetics, the application of filter caps plays a pivotal role in maintaining product standards and consumer safety.

The Role of Filter Caps in Product Development and Quality Assurance

The benefits of filter caps extend beyond merely preventing contamination. They are also instrumental in prolonging the shelf life of products. In liquid formulations, exposure to air can lead to oxidation, microbial growth, and degradation of active ingredients. Filter caps can help mitigate these issues by allowing for controlled ventilation while filtering out airborne particulates. This functionality is especially important for products that are sensitive to environmental factors, such as light and heat.

filter caps product

Moreover, the design and materials used in filter caps can influence product performance. Specialty materials that can withstand various chemical environments ensure that the caps do not interact negatively with the product inside. This compatibility not only safeguards the product's efficacy but also maintains the overall brand reputation for quality. Manufacturers must select filter caps that are not only functional but also suitable for their specific formulations, considering factors such as pH, viscosity, and the presence of preservatives.

Implementing filter caps also contributes to regulatory compliance. Many industries are subject to stringent regulations that govern product safety and quality. Filter caps that meet industry standards provide manufacturers with an added layer of assurance that they are adhering to these regulations. This compliance is not only crucial for maintaining consumer trust but also for avoiding potential legal repercussions associated with non-compliance.

In addition to their protective features, filter caps can support manufacturers in improving their operational efficiency. By minimizing the risk of contamination during the filling and dispensing processes, companies can reduce waste and the costs associated with product recalls. Furthermore, filter caps that are easy to install and replace can streamline production workflows, allowing for faster turnaround times without compromising quality.

In conclusion, filter caps are a vital component in the product development and quality assurance landscape. Their role in preventing contamination, extending shelf life, ensuring regulatory compliance, and enhancing operational efficiency underscores their importance across various industries. As manufacturers continue to prioritize product integrity and consumer safety, the relevance of filter caps will only continue to grow, showcasing their indispensable value in modern manufacturing processes. Recognizing and investing in high-quality filter caps is a crucial step for any company aiming to excel in today’s competitive marketplace.

-

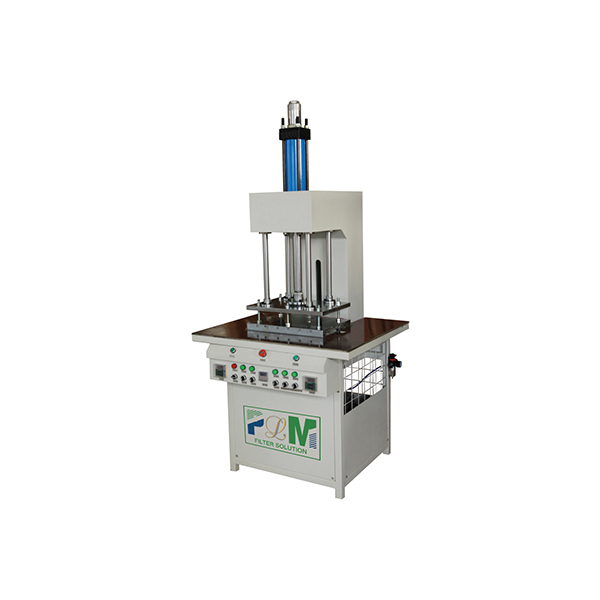

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025