Desemba . 29, 2024 19:50 Back to list

Top Suppliers for Filter Plastic Moulds and Their Innovative Solutions

The Importance of Filtering Plastic Mould Suppliers

In today's rapidly evolving manufacturing landscape, the selection of reliable plastic mould suppliers is critical for businesses aiming to enhance their production efficiency and product quality. With a plethora of options available globally, establishing a robust filtering process to identify the right suppliers can significantly impact a company's operational success. This article explores the importance of filtering plastic mould suppliers and outlines the criteria to consider during this process.

Understanding Plastic Moulding

Plastic moulding is a manufacturing process used to produce parts by injecting molten plastic into a mould. It is a versatile technique that allows for the mass production of complex shapes and components with precision and consistency. However, the effectiveness of the plastic moulding process heavily relies on the quality of the moulds used. Therefore, choosing the right supplier is paramount.

Factors to Consider When Filtering Suppliers

1. Quality and Standards Compliance The foremost criterion for filtering plastic mould suppliers is their adherence to quality standards. Suppliers should possess relevant certifications such as ISO 9001, which demonstrates their commitment to quality management systems. Additionally, compliance with industry-specific standards ensures that the end products meet the necessary safety and performance guidelines.

2. Experience and Expertise A supplier’s experience in plastic moulding can significantly influence the quality of the final products. Suppliers with a proven track record in the industry are more likely to understand the intricacies of mould design and production. They are also better equipped to handle unique challenges that may arise during the manufacturing process.

filter plastic mould suppliers

3. Technological Capabilities The plastic moulding industry is continuously evolving, with advancements in technology leading to improved efficiency and reduced production costs. When filtering suppliers, it's essential to consider their technological capabilities. Suppliers that utilize modern machinery, advanced simulation software, and state-of-the-art design tools can often produce higher quality moulds at a faster pace.

4. Customization and Flexibility Different projects may require different specifications and designs. A good supplier should be flexible and willing to customize mould solutions according to a company's unique requirements. The ability to adapt to changes in design or production volume can be a significant advantage for manufacturers.

5. Cost Competitiveness While quality should never be compromised for cost, it is still essential to evaluate the pricing structures of potential suppliers. Ensuring that pricing aligns with industry standards and provides good value for the services offered is crucial. However, it's important to assess the total cost of ownership, which includes maintenance, shipping, and other hidden costs.

6. Communication and Support Effective communication is vital between manufacturers and suppliers. A supplier that offers excellent customer support can help address issues quickly and efficiently, minimizing downtime during production. It is beneficial to select suppliers who are responsive and open to collaboration.

7. Reputation and Client References Investigating a supplier's reputation within the industry can provide valuable insights into their reliability and performance. Seeking client references and reading testimonials can help in gauging the experiences of other businesses with the supplier. This step allows manufacturers to make an informed decision based on real-world feedback.

Conclusion

In conclusion, filtering plastic mould suppliers is an essential process for any manufacturing business looking to achieve excellence in production. By considering factors such as quality compliance, experience, technological capabilities, customization flexibility, cost competitiveness, communication, and reputation, businesses can select suppliers that align with their operational goals. A thorough filtering process not only ensures that manufacturers receive high-quality moulds but also establishes a strong foundation for long-term partnerships that drive innovation and growth in the plastic moulding industry. Investing time and resources into finding the right supplier can lead to significant benefits, including improved product quality, reduced production costs, and enhanced overall efficiency.

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025

-

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

NewsAug.21,2025

-

Premium Acrylic-Resin Air Filter Paper in Roll | High Efficiency

NewsAug.19,2025

-

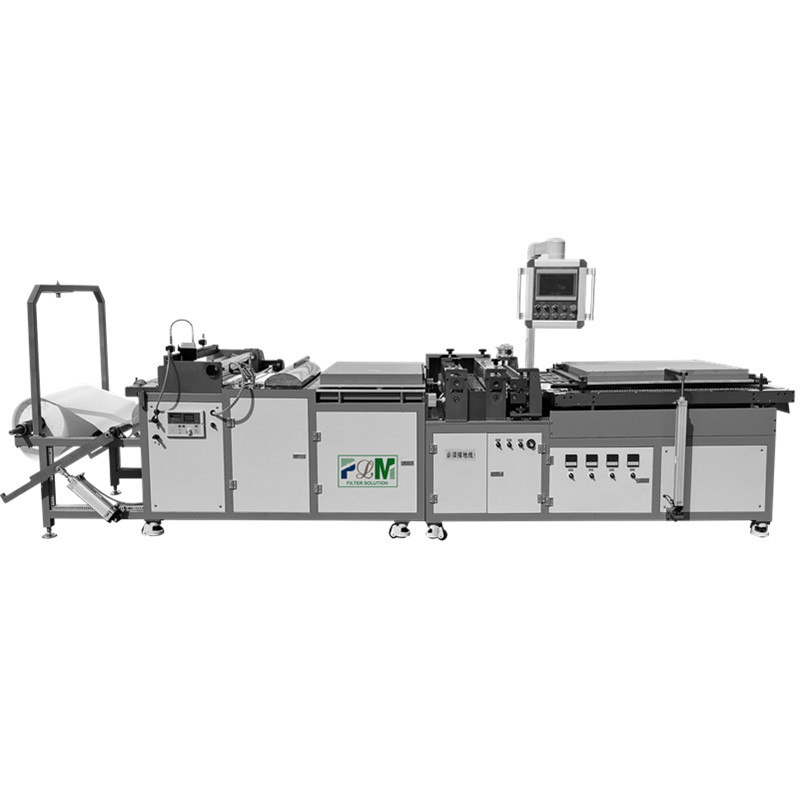

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Production

NewsAug.18,2025