Novemba . 22, 2024 01:23 Back to list

hepa filter paper manufacturers

The Evolution and Impact of HEPA Filter Paper Manufacturers

High-Efficiency Particulate Air (HEPA) filters are pivotal in maintaining air quality across various environments, particularly in healthcare facilities, industrial settings, and residential spaces. The manufacturing of HEPA filter paper is a critical aspect of this industry, ensuring that the filters meet stringent standards for air purification. This article explores the role of HEPA filter paper manufacturers, the technology behind HEPA filters, and the market trends that shape this essential sector.

Understanding HEPA Filters

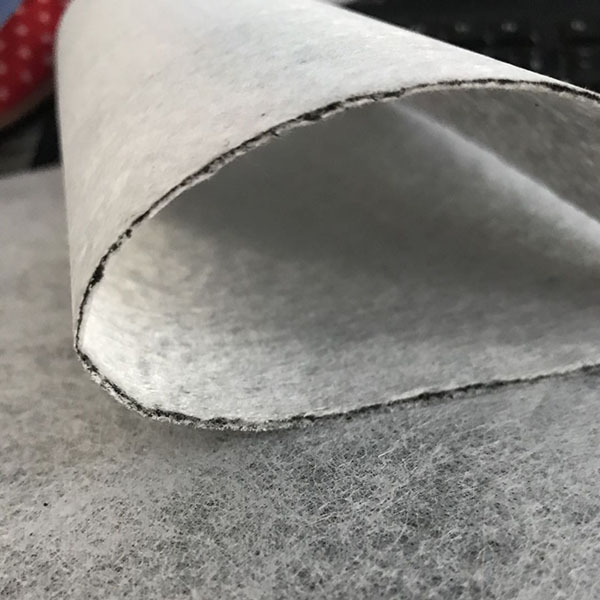

HEPA filters are designed to capture a minimum of 99.97% of particles that are 0.3 microns in size, including dust, pollen, mold spores, and pet dander. The efficiency of these filters lies in their intricate design, which consists of densely packed layers of fiber that trap various airborne particles. The manufacturing process of HEPA filter paper is fundamental to achieving this level of efficiency. The materials used must possess specific characteristics, such as fine fiber diameter, high surface area, and electrostatic properties, which enhance particle collection.

The Manufacturing Process

The production of HEPA filter paper involves several meticulous steps. First, manufacturers source high-quality raw materials, typically synthetic fibers made from polypropylene or polyester. These materials are then subjected to a process called melt-blown, which produces fine-filament fibers through a high-velocity air stream. This process not only creates a labyrinth of fibers but also allows for adjustment in fiber diameter, which is crucial for the filter’s efficiency.

After the fibers are produced, they undergo treatments to enhance their capabilities, such as chemical bonding or electrostatic charging. These enhancements improve the paper's ability to retain particles, thus ensuring the HEPA filter performs at its optimal level. Once the filter paper is produced, it is cut and assembled into various formats, including pleated, panel, or cartridge designs, depending on the intended application.

Market Trends and Demands

hepa filter paper manufacturers

The global demand for HEPA filter paper has surged in recent years, largely driven by heightened awareness of air quality issues and the effects of airborne pollutants on health. The COVID-19 pandemic further accelerated this trend, as businesses and households alike sought effective measures to reduce the transmission of viruses and other pathogens. As a result, the market has witnessed a significant uptick in the adoption of HEPA filters in HVAC systems, air purifiers, and personal protective equipment.

Moreover, the rise of environmental concerns has led to a greater emphasis on sustainable manufacturing processes. HEPA filter paper manufacturers are increasingly focusing on eco-friendly materials and recycling methods. Companies are exploring bioplastics and biodegradable materials to align with global sustainability goals. This shift not only helps reduce the environmental impact of HEPA filters but also appeals to consumers who prioritize green products.

Challenges Facing Manufacturers

Despite the promising growth in the HEPA filter market, manufacturers face several challenges. One major concern is supply chain disruptions, which have been exacerbated by global events such as the pandemic. The sourcing of raw materials can be inconsistent, impacting production schedules and costs. Additionally, manufacturers must continuously innovate to keep up with regulatory changes and advancements in filter technology, necessitating significant investment in research and development.

Competition within the industry is also fierce, with numerous manufacturers vying for market share. This competitive landscape encourages innovation but can lead to price wars that may affect profit margins. Moreover, as more companies enter the market, distinguishing products based on quality and effectiveness becomes increasingly crucial.

Conclusion

HEPA filter paper manufacturers play an essential role in ensuring air quality across various applications. Their commitment to producing high-quality, efficient filter media is vital for public health and safety. As demand continues to grow, these manufacturers must navigate challenges while embracing innovation and sustainability. The future of HEPA filter manufacturing is bright, characterized by advances in technology and a strong focus on protecting both people and the planet.

-

OEM PLKJ-20 Filter Paper Pore Size Tester Precision Measurement

NewsMay.19,2025

-

Affordable PLNP-1 Bursting Strength Tester Low-Cost & Reliable

NewsMay.19,2025

-

Premium Toyota Air Filter Machines OEM Suppliers & Manufacturers

NewsMay.19,2025

-

OEM Truck Air Filters Machine Production Line - Custom Solutions

NewsMay.18,2025

-

Toyota Air Filter Producing Machine High-Efficiency Manufacturing Solutions

NewsMay.18,2025

-

Affordable Truck Air Filters High Quality & Low Cost

NewsMay.18,2025