Desemba . 22, 2024 08:30 Back to list

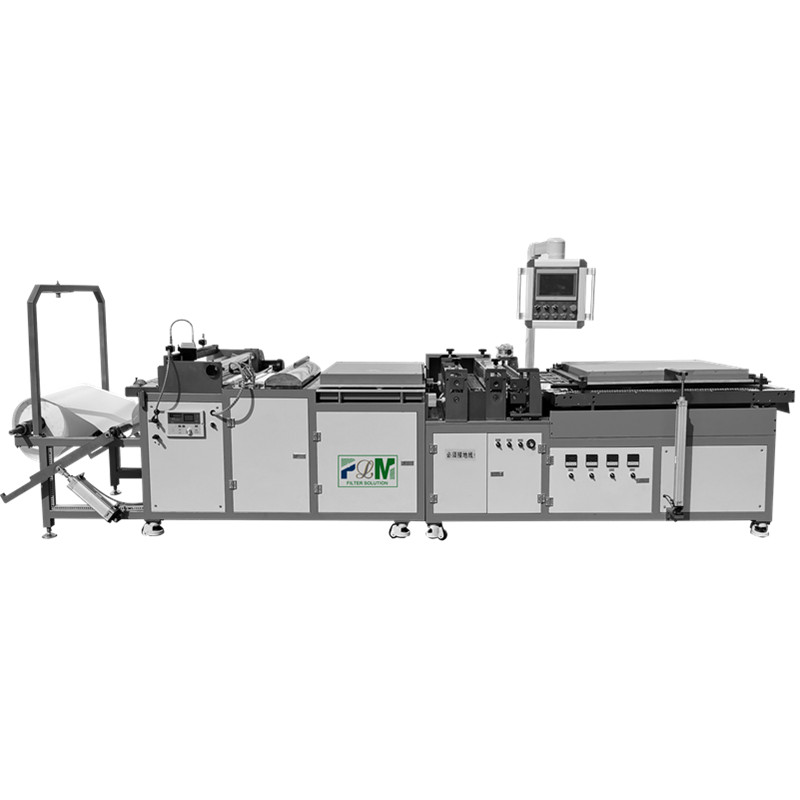

oem trimming machine

Understanding OEM Trimming Machines Efficiency in Precision

In the world of manufacturing, the term OEM (Original Equipment Manufacturer) is synonymous with quality, reliability, and innovation. As industries evolve, the demand for specialized equipment that meets specific production needs has grown significantly. Among these specialized machines, OEM trimming machines stand out for their vital role in enhancing productivity and ensuring that products meet strict quality standards. This article delves into the intricacies of OEM trimming machines, exploring their functions, benefits, and applications across various industries.

What is an OEM Trimming Machine?

An OEM trimming machine is a specialized piece of equipment designed for cutting, trimming, or finishing components to precise specifications. These machines are often custom-built or modified to cater to the unique requirements of a particular manufacturing process. The trimming process is essential in various industries, including automotive, electronics, textiles, and packaging, where precision and consistency are paramount.

Key Features and Functions

1. Precision Cutting One of the primary functions of an OEM trimming machine is to provide precise cutting capabilities. These machines utilize advanced technologies, such as laser cutting, blade trimming, or die cutting, to achieve clean and accurate edges.

2. Versatility OEM trimming machines can be adapted for various materials, including plastics, metals, fabrics, and composites. This versatility allows manufacturers to utilize a single machine for multiple applications, reducing the need for extensive machinery investments.

3. Automation Many OEM trimming machines incorporate automation technologies, such as robotics and computer numerical control (CNC). This automation increases efficiency, reduces labor costs, and minimizes human error, ensuring a consistent output quality.

4. User-Friendly Interfaces Modern trimming machines often come equipped with intuitive control panels and software, simplifying operation and reducing the learning curve for new users. This capability is crucial in maintaining productivity levels in fast-paced manufacturing environments.

5. Safety Features Given the nature of trimming operations, safety is a top priority. OEM trimming machines often include safety guards, emergency stop buttons, and sensors that detect obstructions, ensuring a safe working environment.

oem trimming machine

Benefits of OEM Trimming Machines

1. Enhanced Productivity By automating the trimming process, manufacturers can significantly enhance their production rates. Faster trimming times lead to quicker turnaround without sacrificing quality.

2. Reduced Waste Precision cutting minimizes material wastage, leading to cost savings in raw materials. This efficiency is vital in today’s economy, where resource conservation is increasingly emphasized.

3. Improved Product Quality The accuracy provided by OEM trimming machines ensures that finished products meet stringent quality standards, reducing the likelihood of defective items reaching the market. This reliability leads to higher customer satisfaction and fewer returns.

4. Customization Capabilities Since OEM trimming machines can be tailored to specific processes, manufacturers have the flexibility to adapt to changing product designs or production requirements without investing in new machinery.

5. Long-Term Investment Investing in an OEM trimming machine is often seen as a long-term investment. The durability and reliability of these machines can lead to lower maintenance costs and prolonged service life.

Applications Across Industries

The applications of OEM trimming machines are vast and varied. In the automotive industry, they are used for cutting and trimming components to ensure precise fits, which is crucial for safety and performance. In electronics, these machines handle delicate circuit board trimming, ensuring that components are accurately sized without damage. The textile industry benefits from OEM trimming machines for fabric cutting and complex patterns, while the packaging sector relies on them for precise carton and label trimming.

Conclusion

As industries continue to advance, the role of OEM trimming machines becomes increasingly significant. Their ability to enhance productivity, reduce waste, and improve quality makes them indispensable in modern manufacturing processes. By investing in these specialized machines, manufacturers are not just improving their production lines; they are setting the foundation for sustainable growth and operational excellence in an ever-competitive market. The future of manufacturing lies in precision, and OEM trimming machines are at the forefront of this evolution.

-

Premium OEM Snus Paper Supplier Custom Snus Filter & Packing Papers for Your Brand

NewsJul.05,2025

-

CE Certification PLJL-6 Six-Station Seal Leakage Tester for Spin-On Filter – High Efficiency & Reliability

NewsJul.05,2025

-

OEM PLXB-1 PU Pack Trimming Machine - Precision Cutting, High Efficiency, Reliable Quality

NewsJul.05,2025

-

Premium Engine Oil Filter Supplier & Exporter Reliable Engine Oil Filter Service

NewsJul.04,2025

-

Wholesale PLRZ-1000N Full-Auto Hot Melt Filter Paper Bonding Machine - High Efficiency & Precision

NewsJul.04,2025

-

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025