Novemba . 10, 2024 06:28 Back to list

Service for Air Bubble Tester with PLPB-1% Filter Element

Understanding PLPB-1% Filter Element Air Bubble Tester Service

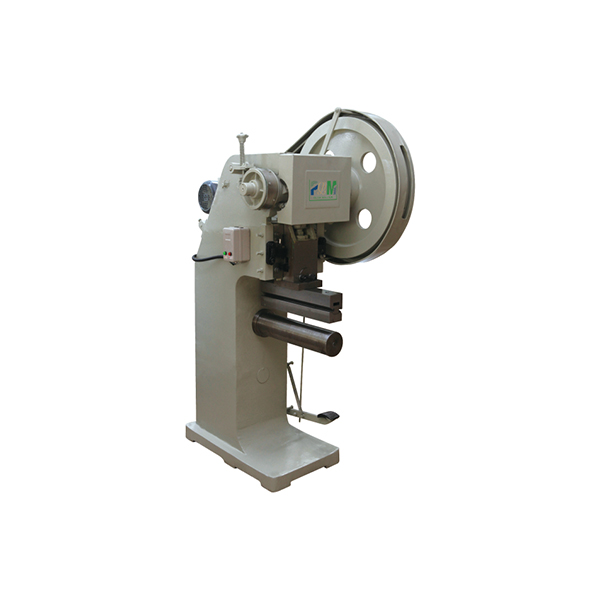

The PLPB-1% Filter Element Air Bubble Tester is an essential device used in various industries to evaluate the integrity of filter elements. This testing service ensures that filters perform optimally and do not allow unwanted particles or contaminants to pass through. With growing concerns regarding air quality, fluid contamination, and overall environmental safety, utilizing devices like the PLPB-1% is becoming increasingly critical.

What is the PLPB-1% Filter Element Air Bubble Tester?

The PLPB-1% is specifically designed to conduct air bubble testing on filter elements. This method involves subjecting the filter to a controlled airflow while immersed in water. If the filter contains defects, such as cracks, pinholes, or any other form of compromise, air bubbles will escape, indicating that the filter is not meeting the required standards for performance.

This method of testing is highly effective due to its simplicity and reliability. It is applicable to a wide range of filter types, including those used in air, liquid, and gas filtration processes. By utilizing the PLPB-1%, industries can ensure that their products conform to stringent quality assurance protocols.

Importance of Regular Testing

Regular testing of filter elements is crucial for several reasons

1. Quality Assurance Maintaining high standards of quality is vital in industries such as pharmaceuticals, food and beverage, and aerospace. Even the smallest defect in a filter can lead to significant contamination issues.

2. Operational Efficiency Filters that are compromised can hinder the overall performance of a system. For example, a faulty filter in an industrial machine can lead to increased wear and tear, potentially causing downtime and costly repairs.

3. Compliance and Safety Many industries are governed by regulations that mandate specific testing procedures to ensure product safety and environmental compliance. Using the PLPB-1% tester helps businesses adhere to these regulations and avoid legal repercussions.

plpb-1 filter element air bubble tester service

4. Cost-Effectiveness Identifying and rectifying filter issues before they escalate can save organizations significant resources. Regular testing minimizes the risk of unexpected failures and the associated costs of emergency repairs or product recalls.

The Testing Process

The testing process using the PLPB-1% Filter Element Air Bubble Tester generally encompasses several key steps

1. Preparation The filter element to be tested is first inspected for any visible damage. It is then prepared according to the manufacturer's specifications.

2. Submersion The prepared filter element is submerged in a water bath while a controlled flow of air is introduced.

3. Observation The tester observes the filter for any air bubbles escaping. The presence of bubbles indicates that the filter has a defect.

4. Analysis and Reporting Results are compiled and analyzed to determine the filter’s integrity. If defects are detected, recommendations for repair or replacement are provided.

Conclusion

In an era where contamination control is more critical than ever, the PLPB-1% Filter Element Air Bubble Tester service plays a pivotal role in assuring filter integrity and performance across various industries. By regularly testing filter elements, businesses can enhance operational efficiency, ensure compliance with safety regulations, and uphold product quality. Investing in such testing services not only contributes to maintaining high standards within the industry but also fosters trust and reliability among customers and stakeholders.

For organizations committed to maintaining excellence in their filtration systems, the PLPB-1% is not just a tool but a necessary component of their quality assurance regimen. Embracing this technology reflects a proactive approach to preventing contamination and safeguarding both products and consumers alike.

-

Animal Semen Filter Paper High Porosity & Superior Filtration

NewsJun.08,2025

-

High-Efficiency Filter Manufacture Machine Precision Automation

NewsJun.08,2025

-

Vacuum Filter Machine Reliable Industrial Equipment Supplier

NewsJun.08,2025

-

Premium Air Carbon Filter for Odor Removal & Pure Air

NewsJun.07,2025

-

PLCB-500 CE Certified Full-Auto Cabin Air Filter Gluing Machine

NewsJun.07,2025

-

Napa Gold 4003 Wix 24003 Premium Oil Filters for Engine Protection

NewsJun.07,2025