Oct . 10, 2025 20:00 Back to list

Orange PU Glue: Strong, Flexible Adhesive for Metal & More

Unlocking Global Opportunities: Top Auto Parts & Filter Element Manufacturers at the 135th Canton Fair

The 135th Canton Fair, a beacon of global trade, once again played host to an unparalleled showcase of innovation and manufacturing prowess. For B2B decision-makers in the automotive sector, this event was a critical juncture, particularly for sourcing high-quality auto parts and filter elements. As an exhibitor, the fair provided an invaluable platform for leading manufacturers and traders to unveil their latest advancements, demonstrate their commitment to excellence, and forge new international distribution partnerships and bulk buying agreements. The sheer scale and diversity of suppliers, ranging from established giants to agile innovators, underscore its immense value for the global automotive filtration industry.

This year's focus extended beyond mere product display; it was about strategic collaboration, technological synergy, and building resilient supply chains. Manufacturers of filter elements, in particular, highlighted how their products meet stringent global standards, ensuring vehicle longevity, optimal performance, and occupant health.

Industry Trend Spotlight: Navigating the Evolving Filtration Landscape

The automotive filtration market is undergoing a significant transformation, driven by an confluence of technological advancements, environmental regulations, and shifting consumer expectations. At the 135th Canton Fair, several key trends dominated discussions:

- Growing Demand for High-Performance & Eco-Friendly Filters: There's an undeniable shift towards filters that offer superior filtration efficiency while minimizing environmental impact. This includes longer-lasting materials, biodegradable components, and designs that reduce waste.

- Advanced Cabin Air Filtration Systems: With increasing concerns over air quality, sophisticated cabin air filters incorporating HEPA standards, anti-viral properties, and active carbon layers are becoming standard. These systems are crucial for maintaining a healthy interior environment, especially in urban areas.

- Integration of IoT for Filter Monitoring: Smart filters equipped with sensors for real-time monitoring of filter life and performance are emerging. This technology promises predictive maintenance, optimized replacement cycles, and reduced vehicle downtime.

- Specialized Filtration for Hybrid and Electric Vehicles (EVs): While EVs don't require traditional engine oil or fuel filters, they introduce new filtration challenges. This includes filters for battery cooling systems, advanced HVAC systems for thermal management, and specialized cabin air filters to manage the unique interior environment of electric vehicles.

Market Data Insights: The global automotive filter market is projected for steady growth, particularly in the aftermarket segment and emerging economies. Key drivers include a burgeoning global vehicle parc, increasingly stringent emission regulations, and a heightened focus on occupant health and comfort (especially cabin air quality). While electrification poses long-term shifts, traditional Internal Combustion Engine (ICE) vehicle filters will remain significant for decades to come, complemented by new and evolving filtration requirements for EVs.

Emerging focus areas for manufacturers include sustainable and high-efficiency filtration solutions, integration of smart manufacturing into supply chains, enhancing global trade resilience, and proactive adaptation to the unique filtration needs of the evolving EV market. Ensuring the integrity and durability of these advanced filter elements often relies on state-of-the-art adhesive technologies. Products like orange PU glue, black PU glue, red PU glue, hot melt sticks, hot melt adhesive, polyester glue, metal cap stick glue, metal caps glue, and various types of AB glue and PU glue are indispensable for securely bonding filter media, end caps, and housings, ensuring leak-proof seals and structural stability under extreme operating conditions. These adhesive solutions are fundamental to achieving the performance and longevity demanded by modern filtration systems.

Profiles of Leading Companies Driving Innovation

The 135th Canton Fair highlighted numerous companies that are shaping the future of auto parts and filter elements. Among the notable participants, China's manufacturing prowess was on full display.

Hebei Filter Man Automotive Parts Trading Co., Ltd

A prominent exhibitor, Hebei Filter Man Automotive Parts Trading Co., Ltd, showcased its specialized expertise in a comprehensive range of automotive filtration products. As their name suggests and their website mfiltersolution.com attests, this company offers focused solutions tailored to the precise needs of international buyers. Strategically located in Hebei, a key industrial region in China, they benefit from robust supply chain access, enabling efficient sourcing and competitive manufacturing.

As a trading company, Hebei Filter Man is uniquely positioned to offer distinct advantages: competitive pricing due to volume sourcing, broad product capabilities across various filter types, and established international logistics experience ensuring smooth, timely deliveries worldwide. Their commitment extends to the foundational materials that ensure the quality and durability of filter elements, including a wide array of high-performance adhesives. These critical components, such as their featured hot melt glue, are essential for assembling robust and reliable filters that meet demanding automotive specifications. Products like orange PU glue for vibrant industrial applications, durable black PU glue for robust seals, specialized red PU glue for specific bonding requirements, and versatile hot melt sticks and hot melt adhesive are crucial for the structural integrity and sealing performance of filter elements. They also supply specialized polyester glue, metal cap stick glue, metal caps glue, AB glue, and general PU glue, all vital for manufacturing top-tier filters.

Here are some examples of the types of products essential for filter manufacturing, aligning with their focus:

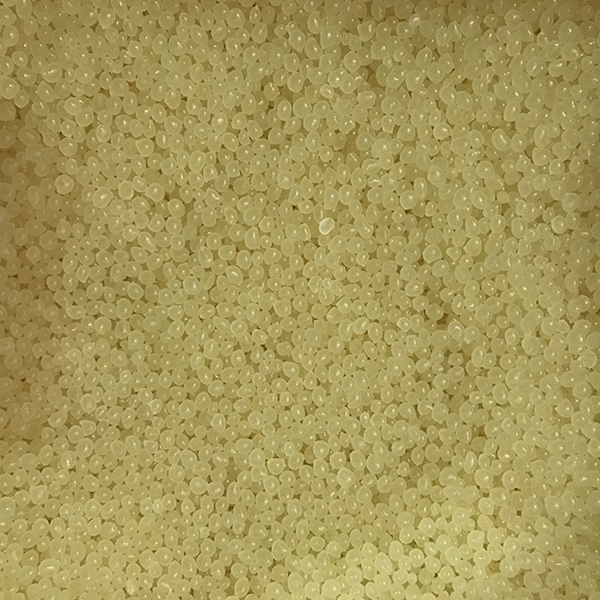

Orange PU Glue

Black PU Glue

Red PU Glue

Hot Melt Sticks

Polyester Glue

AB Glue

Other Global Leaders and Regional Innovators

Beyond the significant presence of Chinese manufacturers and traders like Hebei Filter Man, the global automotive filtration landscape is also shaped by renowned international players. Companies such as Mann+Hummel, Mahle GmbH, Donaldson Company, Inc., Sogefi S.p.A., Bosch, and Fram Filtration continue to drive innovation in filtration technology. Their R&D efforts often set industry benchmarks, particularly in advanced media, housing designs, and, importantly, the adhesive technologies that hold these complex structures together. Many regional auto parts traders and manufacturers also contributed to the Canton Fair's vibrant ecosystem, showcasing specialized products and competitive solutions, further emphasizing the crucial role of durable adhesives like metal cap stick glue and robust hot melt adhesive in the construction of their filter element offerings.

Market Outlook & Strategic Opportunities for Buyers

The future of the auto parts and filter element market is dynamic, offering significant opportunities for discerning buyers. Upcoming trends point towards increased demand for highly specialized filters catering to various vehicle types and environmental conditions. Buyers are increasingly seeking suppliers who can provide not just products, but comprehensive solutions that align with global trends.

- Automation & Smart Manufacturing: The adoption of automation in filter production lines, combined with smart manufacturing processes, is leading to higher quality, greater consistency, and more cost-effective products. This translates into reliable supply for buyers.

- Sustainability & Circular Economy: There's a growing emphasis on sustainable manufacturing practices, from raw material sourcing to end-of-life recycling for filters. Buyers who prioritize eco-friendly options will find a growing selection of compliant products.

- Innovation in Materials: The continuous development of new filter media, housing materials, and advanced adhesives – including new formulations of PU glue and specialized hot melt adhesive – is crucial for meeting performance demands for greater efficiency, durability, and lighter weight. This allows for smaller, yet more effective filter elements.

The Canton Fair underscored that manufacturers are rapidly integrating these opportunities into their operations, making it an ideal venue for buyers to discover partners capable of meeting future market demands.

Buyer/Business Takeaways: Strategic Sourcing and Future-Proofing

For B2B decision-makers, investing in high-quality auto parts and filter elements from reputable manufacturers makes undeniable business sense. Here's why and how to navigate this evolving landscape:

- Enhanced Performance & Customer Satisfaction: Superior filter elements directly contribute to vehicle performance, fuel efficiency, and occupant health, leading to higher customer satisfaction and repeat business. The reliability provided by quality adhesives like polyester glue and AB glue in filter assembly is paramount here.

- Cost-Effectiveness in the Long Run: While initial investment might seem higher, durable, high-performance filters reduce replacement frequency and prevent costly damages to vehicle systems, offering long-term savings.

- Meeting Regulatory Compliance: Partnering with manufacturers committed to international standards ensures your offerings meet current and future emission and safety regulations.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Due Diligence is Key: Thoroughly vet potential partners for quality certifications, production capabilities, and ethical practices. Factory visits (virtual or in-person) are invaluable.

- Clarity in Communication: Clearly articulate your specifications, quality control standards, and logistical requirements. Companies like Hebei Filter Man Automotive Parts Trading Co., Ltd, with their international experience, are adept at handling such complexities.

- Focus on Innovation & R&D: Seek manufacturers who invest in research and development, particularly in new materials and adhesive technologies (e.g., advanced PU glue formulations for extreme temperatures or highly resistant hot melt adhesive). This ensures access to cutting-edge products.

- Build Long-Term Relationships: Establishing trust and fostering long-term partnerships often leads to better pricing, customized solutions, and preferential service.

Future-Proof Strategies: To stay ahead, businesses should diversify their supply chains, integrate smart technologies for inventory and quality management, and continuously monitor emerging trends in EV filtration and sustainable manufacturing. Ensuring your suppliers, like those featured at the Canton Fair, utilize advanced materials and precise bonding agents such as metal caps glue or robust orange PU glue for their filter element production is crucial for maintaining competitive advantage and product excellence.

Conclusion: The Canton Fair's Enduring Impact

The 135th Canton Fair once again affirmed its critical role in shaping the global auto parts and filter element market. It served as a vital nexus for innovation, collaboration, and strategic sourcing, connecting international buyers with a vast array of high-quality manufacturers and traders. From the latest advancements in eco-friendly filters to the crucial role of specialized adhesives like hot melt glue in ensuring filter integrity, the fair highlighted the industry's commitment to performance, sustainability, and technological advancement.

For those seeking to explore top-tier filtration components and the essential materials that underpin their quality, we invite you to learn more about the critical role of adhesives in filter manufacturing. Discover how high-performance hot melt adhesive, various PU glue options, and other bonding solutions contribute to the durability and efficiency of modern filter elements.

To delve deeper into advanced adhesive solutions for filter manufacturing, visit:

https://www.mfiltersolution.com/hot-melt-glue-34.html

active carbon air filter for air purifier – Odor/VOC Control

NewsNov.17,2025Replacement Dyson Carbon HEPA Air Filter – High Efficiency

NewsNov.17,2025Active Carbon Air Filter for Air Purifier | High Adsorption

NewsNov.17,2025Active Carbon Air Filter for Air Purifier | Odor & VOC Control

NewsNov.17,2025Active Carbon Air Filter for Air Purifier | Odor & VOC

NewsNov.17,2025Sintered Porous Metal Filter Tube Cup | 5 Micron, SS316L

NewsNov.11,2025