டிசம்பர் . 01, 2024 06:30 Back to list

plgt-420 full-auto rotary eco filter paper pleating production line service

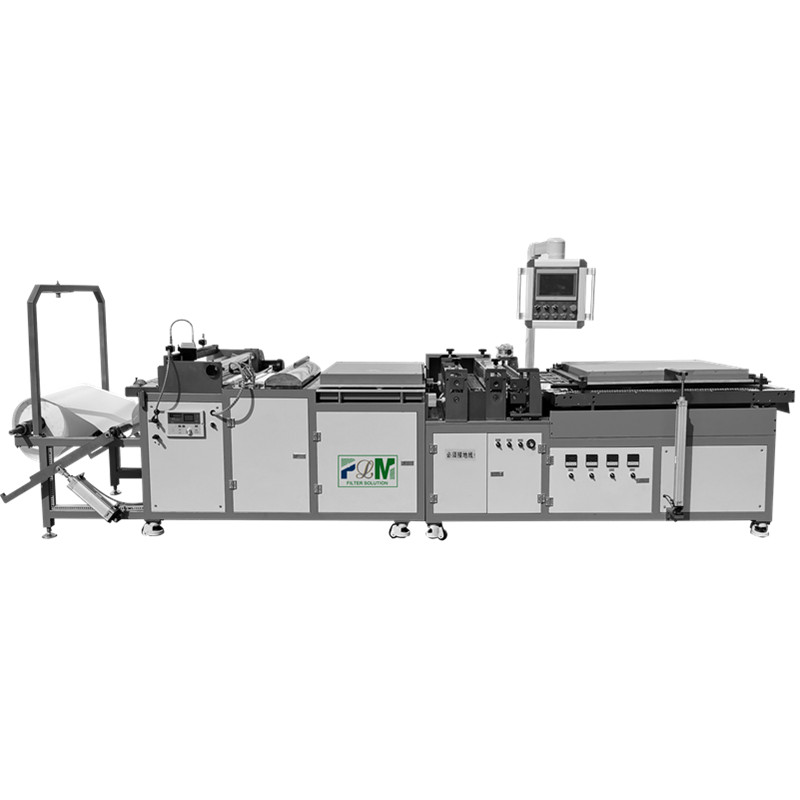

The PLGT-420 Full-Auto Rotary Eco Filter Paper Pleating Production Line A Comprehensive Overview

In today's industrial landscape, the demand for environmentally friendly products continues to rise, particularly in the filtration industry. One of the key innovations facilitating this transition is the PLGT-420 Full-Auto Rotary Eco Filter Paper Pleating Production Line. This state-of-the-art machinery streamlines the production of eco-friendly filter papers, meeting the growing needs for sustainable solutions in air and water filtration.

Leading Technology in Filter Paper Production

The PLGT-420 represents the pinnacle of modern engineering in the realm of filter paper production. Designed with advanced technology, this full-automatic machine significantly reduces manual labor while increasing efficiency and output quality. The rotary pleating system allows for precise and consistent pleat formation, a critical element in maximizing the surface area of the filter paper for enhanced filtration performance.

This production line is not only about efficiency; it is also committed to sustainability. The eco filter papers produced on the PLGT-420 are designed to meet stringent environmental standards. They often utilize biodegradable materials and processes that minimize waste, aligning with global efforts to reduce plastic usage and promote sustainability.

Key Features and Advantages

1. Full Automation The PLGT-420 is engineered for full automation, which greatly reduces the need for manual intervention. This not only speeds up the production process but also minimizes human error, ensuring that each sheet of filter paper meets high quality standards.

2. Rotary Pleating Mechanism At the heart of the PLGT-420 is its innovative rotary pleating mechanism. This system allows for quick adjustment to different pleat sizes and configurations, enabling manufacturers to produce a wide range of filter papers tailored to specific applications, whether in automotive, industrial, or household filters.

3. High Efficiency Capable of producing a substantial amount of filter paper in a short period, the PLGT-420 is designed to maximize output without compromising quality. This high throughput makes it an attractive investment for manufacturers aiming to meet increasing market demands.

plgt-420 full-auto rotary eco filter paper pleating production line service

4. User-Friendly Interface The machine is equipped with an intuitive control panel, making it easy for operators to monitor and adjust settings. This simplifies the training process and enhances overall operational efficiency.

5. Energy Efficiency In addition to its sustainable production capabilities, the PLGT-420 is designed to operate with minimal energy consumption. This aspect not only lowers production costs but also minimizes the environmental footprint of the manufacturing process.

Applications of Eco Filter Papers

The eco filter papers produced by the PLGT-420 are versatile and find applications across various sectors. These include, but are not limited to

- Automotive Filtration Filter papers are critical in vehicle engines, enhancing fuel efficiency and reducing emissions. - Air Conditioning and Ventilation Systems Quality air filters are essential for maintaining indoor air quality, making this product invaluable in residential and commercial HVAC systems. - Water Filtration With growing concerns over water quality, eco filter papers are increasingly used in purification systems to provide clean drinking water. - Industrial Processes Many manufacturing processes require filtration solutions, making the PLGT-420’s output crucial for industries ranging from pharmaceuticals to food and beverage.

Conclusion

The PLGT-420 Full-Auto Rotary Eco Filter Paper Pleating Production Line sets a new standard in the production of environmentally friendly filter papers. Its advanced features and commitment to sustainability not only enhance efficiency but also align with the increasing global focus on eco-conscious manufacturing solutions.

As the industry continues to evolve, machinery like the PLGT-420 will play a pivotal role in addressing the dual challenges of growing filtration needs and environmental responsibility. For manufacturers looking to invest in the future of filtration technology, the PLGT-420 represents a robust and forward-thinking option that balances productivity with ecological sustainability.

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.26,2025

-

Active Carbon Air Filter for Air Purifier – Efficient Odor & Allergen Removal

NewsJul.25,2025

-

Active Carbon Air Filter for Air Purifier – Superior Odor & Allergen Removal

NewsJul.24,2025

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025