நவ் . 10, 2024 07:21 Back to list

Bevel Trimming Machines for PLHL-1% Cabin Filter Production by Leading Manufacturers

Exploring the World of PLHL-1% Cabin Filter Bevel Trimming Machine Manufacturers

The automotive industry has seen significant advancements in manufacturing processes, particularly concerning the production of cabin filters. Among the essential machinery used in this domain is the PLHL-1% cabin filter bevel trimming machine. As manufacturers strive for high precision and efficiency, understanding the role of these machines becomes essential for enhancing production quality and meeting market demands.

The cabin filter plays a crucial role in maintaining clean air quality within vehicles, directly impacting the comfort and health of passengers. With the increasing awareness of air quality and environmental factors, the demand for high-performance cabin filters has risen sharply. Manufacturers are therefore focusing on optimizing their production processes, and this is where the PLHL-1% bevel trimming machine comes into play.

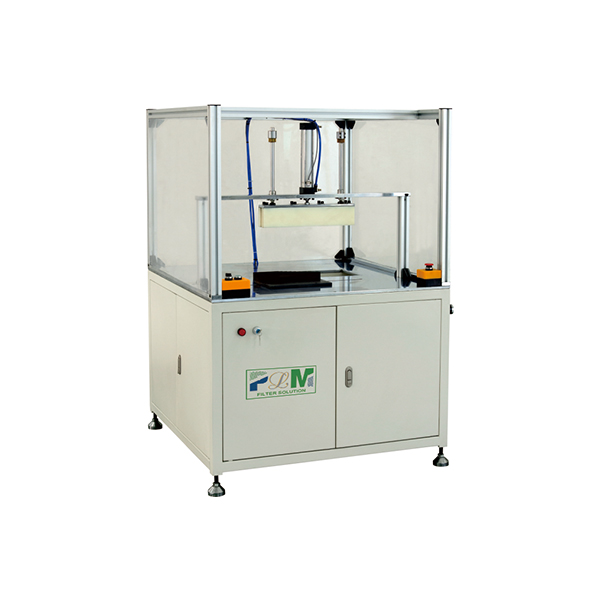

The PLHL-1% cabin filter bevel trimming machine is specifically designed to provide precise trimming of the edges of cabin filters, creating a bevel that enhances the fit and performance of the final product

. The machine's advanced technology ensures that every cut is uniform and precise, which is essential for maintaining the filter's effectiveness in blocking contaminants.Manufacturers of the PLHL-1% machine are often characterized by their commitment to innovation and quality. Many of these companies invest heavily in research and development to improve the functionality and efficiency of their machines. By integrating automatic features, these manufacturers increase production speeds while minimizing waste, thus promoting sustainability in their operations.

plhl-1 cabin filter bevel trimming machine manufacturers

One key aspect to consider when assessing PLHL-1% manufacturers is their technology adoption. Leading manufacturers utilize advanced software and automation in their machinery, enabling precise control over the trimming process. This level of sophistication not only ensures high-quality output but also reduces labor costs as machines can operate with minimal human intervention.

Additionally, manufacturers focus on the durability and maintenance of their machines. A well-built bevel trimming machine will withstand the rigors of constant operation, reducing downtime and maintenance costs for businesses. Quality manufacturers often provide extensive customer support and service agreements, ensuring that their clients can optimize machine performance throughout its lifespan.

The global market for cabin filters is competitive, and manufacturers must adapt to changing consumer demands and regulatory requirements. The PLHL-1% cabin filter bevel trimming machine plays a strategic role in this adaptation, allowing manufacturers to produce high-quality filters that comply with environmental standards. The ability to produce filters that effectively capture pollutants while being eco-friendly is becoming increasingly important, and innovative trimming solutions contribute to this goal.

When choosing a PLHL-1% cabin filter bevel trimming machine manufacturer, businesses should consider several factors. Beyond the machine's technical specifications and pricing, potential buyers should investigate the company's reputation, customer reviews, and after-sales support. Companies with a strong track record of customer satisfaction and a commitment to ongoing innovation are often the best partners for achieving production excellence.

In conclusion, the PLHL-1% cabin filter bevel trimming machine represents a significant advancement in the production of cabin filters. Manufacturers focusing on precision, efficiency, and sustainability are poised to lead the automotive industry forward. As air quality continues to be a priority for consumers, investing in high-quality manufacturing solutions will ensure that businesses remain competitive and meet the evolving demands of the market. By understanding the role of bevel trimming technology, manufacturers can better position themselves within the landscape of automotive component production.

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025

-

China PLMF-1 Auto Sealing Ring Assembly Line Efficient Precision Production

NewsJun.09,2025

-

Premium China 171194 Crinkled Coffee Filter Paper - High-Quality Filtration

NewsJun.09,2025

-

China 1869991 High-Quality Industrial Components Supplier

NewsJun.08,2025