Nov . 23, 2024 23:50 Back to list

Buy Truck Air Filter Production Equipment for Efficient Manufacturing Solutions

The Rise of Truck Air Filter Making Machines A Necessary Investment

In the world of heavy-duty vehicles, maintaining performance and durability is critical. Truck air filters play a crucial role in this equation, ensuring that engines function efficiently by preventing dirt, dust, and other contaminants from entering. As the demand for trucks continues to rise, so does the need for efficient air filter production. This leads to an interesting phenomenon the increasing investment in machines for manufacturing truck air filters.

Understanding the Importance of Air Filters

Truck air filters serve as the lungs of heavy-duty engines. They ensure that the air entering the engine is clean, which is vital for optimal combustion. A clogged or dirty air filter can dramatically affect engine performance, leading to increased fuel consumption, reduced power output, and even engine damage in extreme cases. Therefore, regular replacement of air filters is essential for maintaining a truck’s health and longevity.

With the trucking industry experiencing steady growth, fueled by e-commerce and the demand for goods transportation, the need for high-quality air filters has surged. This presents an opportunity for entrepreneurs and businesses to consider investing in air filter making machines.

The Composition of Air Filter Manufacturing

Air filters are composed of various materials such as paper, foam, or synthetic fibers. The manufacturing process requires precision in terms of material selection, cutting, shaping, and assembly. The rise of automation has made it easier and more cost-effective to produce air filters at scale. Investing in an air filter making machine not only speeds up the production process but also enhances consistency and quality.

Modern air filter making machines are designed to handle various materials and can produce different types of filters tailored to specific truck models or environmental conditions

. This flexibility allows manufacturers to meet the growing world's demands.buy truck air filters making machine

Cost-Benefit Analysis

Initially, the investment in air filter making machines may seem daunting. The costs can range from tens of thousands to several hundred thousand dollars, depending on the machine's complexity and capabilities. However, the long-term savings and potential profits can far outweigh these initial costs.

By producing air filters in-house, businesses can significantly reduce their operating costs associated with sourcing from external suppliers. They can also control quality better, ensuring that the filters meet or exceed industry standards. Moreover, having the capability to innovate and introduce new filter designs can provide a competitive edge in the market.

Exploring Market Trends

The market for truck air filters is expected to continue growing, driven by advancements in technology and increased awareness of environmental standards. Diesel engines, which are common in trucks, are under pressure to meet stricter emission regulations. This has led to the development of high-efficiency air filters that capture finer particles compared to traditional models. The ability to manufacture such filters in-house can position a business as a leader in the industry, catering to environmentally conscious consumers and regulatory compliance.

Furthermore, the rise of electric trucks also presents an opportunity. While traditional air filters remain critical for combustion engines, electric vehicles also require filtration systems for cabin air quality and cooling components. Adaptable air filter manufacturing systems can branch into this emerging market, signaling the importance of machine investment with versatile capabilities.

Conclusion

In conclusion, the investment in truck air filter making machines is not just about keeping pace with a growing market; it is about taking proactive steps toward ensuring efficiency, quality, and sustainability in the trucking industry. As the landscape continues to evolve, businesses that recognize the value of producing their own air filters will thrive. By leveraging technology, innovation, and a commitment to quality, manufacturers can capitalize on a trend that is here to stay—ensuring that the engines of the future run as smoothly and efficiently as possible.

-

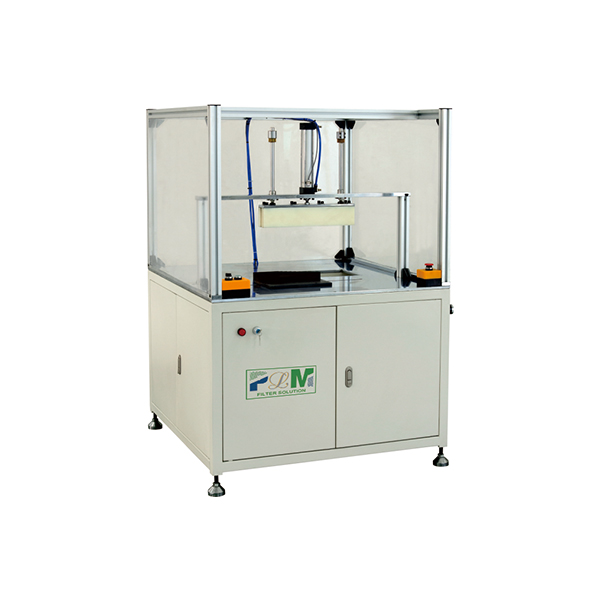

OEM PLXB-1 PU Pack Trimming Machine - High Precision, Durable, Cost-Effective Solutions

NewsJun.10,2025

-

High-Performance In Line Fan Filter Trusted In Line Fan Filter Company & Products

NewsJun.10,2025

-

High-Efficiency Water Filter Making Machine Reliable Companies & Products

NewsJun.10,2025

-

Premium Metal Fuel Filter Durable & Efficient for Engine Protection

NewsJun.10,2025

-

Premium OEM 304 Rimmed Filter Disc Custom Stainless Steel Filters

NewsJun.10,2025

-

China PP Air Filter Production Line Automated & High-Efficiency Solutions

NewsJun.10,2025