พ.ย. . 07, 2024 08:24 Back to list

compressor air filter service

The Importance of Regular Compressor Air Filter Service

Compressed air systems play a critical role in various industrial applications, providing power for machinery, tools, and processes. However, the efficiency and longevity of these systems can be greatly affected by the condition of the air filters. Regular compressor air filter service is essential for maintaining optimal performance, reducing energy costs, and ensuring the longevity of your equipment.

What is an Air Filter in a Compressor?

The air filter in a compressor is designed to trap dust, dirt, and other contaminants from the air before it enters the compressor itself. These particles can cause significant damage and operational issues if allowed to circulate through the system. Therefore, an efficient air filtration process is crucial to maintaining clean air, which ultimately contributes to the compressor's efficiency and reliability.

Why Regular Service is Essential

1. Prevention of Contamination A clean air filter helps prevent the ingress of contaminants into the compressor. When filters become clogged, they restrict airflow, leading to increased pressure on the compressor. This restriction can cause the machine to work harder, increasing energy consumption and wear on internal components. Regular servicing of air filters ensures they are clean and functioning effectively, which minimizes the risk of contamination.

compressor air filter service

2. Energy Efficiency Clogged filters can significantly reduce the efficiency of your air compressor. When the airflow is restricted, the compressor must use more energy to maintain the same output. This can lead to higher electricity bills and operational costs. Regularly servicing air filters keeps them clean, ensuring that the compressor operates at its optimal efficiency, ultimately saving energy and money.

3. Prolonging Equipment Life By maintaining clean air filters through regular service, you significantly extend the life of your compressor. Contaminants that are allowed to enter the system can lead to excessive wear and tear, resulting in costly repairs or even premature failure of the compressor. Preventive maintenance, including filter service, helps mitigate this risk, allowing the equipment to perform reliably for a longer period.

4. Improved Air Quality In industries where compressed air is used for processes such as painting, food processing, or pharmaceuticals, air quality is paramount. Clogged or dirty air filters can lead to poor air quality, which may lead to defects in products or contamination in processes. Regularly servicing air filters ensures that the air quality remains high, safeguarding the integrity of the products and processes that rely on compressed air.

5. Compliance and Safety Many industries must adhere to strict regulations regarding air quality and operational safety. Regular air filter service helps ensure compliance with these standards. Additionally, maintaining clean filters can prevent potential safety hazards related to equipment failure.

Conclusion

In summary, the importance of regular compressor air filter service cannot be overstated. It plays a vital role in preventing contamination, improving energy efficiency, prolonging equipment life, ensuring high air quality, and maintaining compliance with industry regulations. Establishing a routine maintenance schedule for air filters not only enhances the performance of your compressor but also contributes to the overall reliability and productivity of your operations. Investing in filter service is an investment in the longevity and efficiency of your compressed air system.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

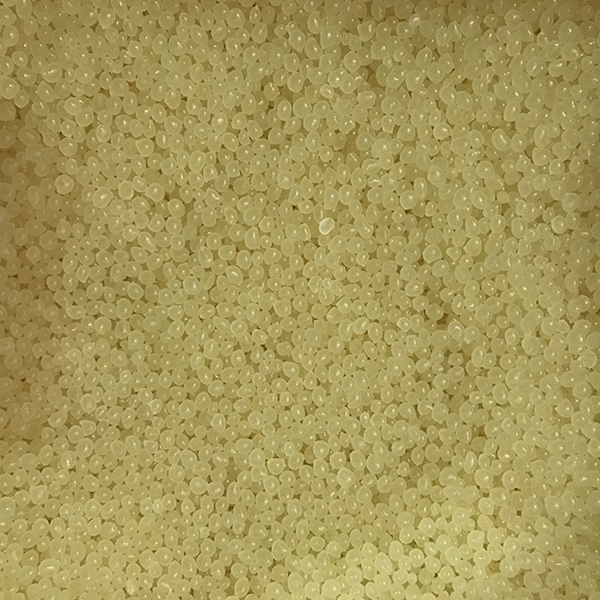

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025