Ноя . 04, 2024 05:16 Back to list

filter paper pleating machine service

The Importance of Filter Paper Pleating Machine Services

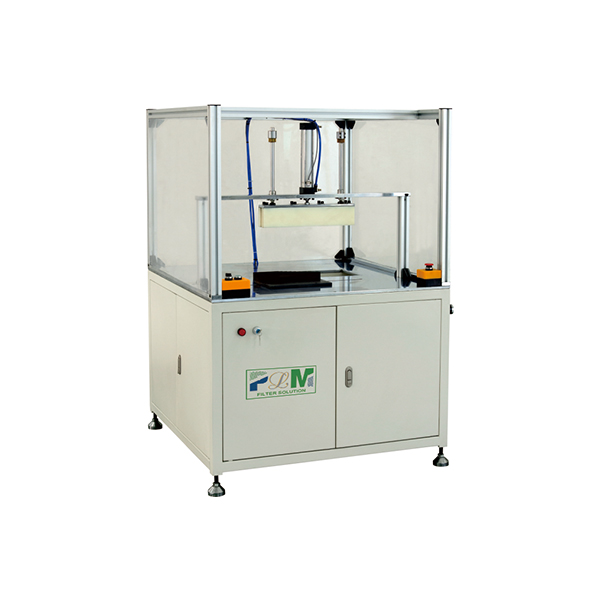

In today’s fast-paced industrial environment, efficiency and precision are paramount, especially in the production of filter paper products. Filter paper pleating machines have emerged as critical equipment in the manufacturing process, enabling companies to produce high-quality filter paper in bulk. However, to maintain optimal performance, regular servicing of these machines is essential.

Filter paper is widely used in various applications, including laboratory analysis, air and liquid filtration, and food processing. These applications demand filters that are not only effective but also consistent in quality. This is where filter paper pleating machines come into play. They are designed to fold and crease the filter paper in specific patterns to enhance its filtering capacity and ensure that it fits seamlessly into different filter housings.

The effectiveness of these machines directly correlates with how well they are maintained. Regular servicing is crucial to prevent unexpected breakdowns that can halt production and lead to significant financial losses. A well-maintained machine operates at peak efficiency, ensuring that the pleating process is consistent and accurate, which is vital for producing high-quality filter products.

Several key components of filter paper pleating machines require regular attention the feeding mechanism, pleating dies, and electrical systems. The feeding mechanism needs to be regularly checked and calibrated to ensure that the paper is fed smoothly into the pleating area. Any misalignment can lead to uneven pleats, resulting in inferior filter quality.

filter paper pleating machine service

The pleating dies, which shape the filter paper into its final form, should also be inspected for wear and tear. Over time, these dies can become dull or damaged, leading to improper pleating. Regular maintenance services can replace or sharpen these dies, ensuring that the pleating process remains efficient and effective.

Moreover, the electrical systems that power these machines require routine checks. Electrical faults not only disrupt the operation but can also pose safety hazards for operators. A professional service provider will not only troubleshoot these issues but will also perform necessary upgrades to keep the machines compliant with safety regulations.

Additionally, companies should consider the benefits of preventive maintenance contracts. Engaging a service provider to conduct regular inspections and maintenance can save time and resources in the long run. These contracts typically include scheduled check-ups, which can be tailored to the production schedule of the company. Such proactive measures can help identify potential issues before they escalate, minimizing downtime and extending the lifespan of the machines.

In today's competitive marketplace, companies that invest in the regular servicing of their filter paper pleating machines set themselves apart. By ensuring that their equipment operates reliably and efficiently, they can maintain high standards of product quality, meet customer demands promptly, and ultimately enhance their bottom line.

In conclusion, filter paper pleating machine service is not just a maintenance requirement; it is a strategic investment in quality assurance and operational efficiency. By prioritizing regular servicing, companies can ensure their machines remain in top condition, yielding high-quality filter paper products that meet industry standards and customer expectations.

-

High-Efficiency Active Carbon Air Filter for Air Purifier | Odor & Allergen Removal

NewsJul.23,2025

-

Active Carbon Air Filter for Air Purifier – High Efficiency Filtration Solution

NewsJul.22,2025

-

Durable Sintered Porous Metal Filter Tube Cup & Machines

NewsJul.22,2025

-

Effective Active Carbon Air Filter for Purifiers | Eliminate Odors

NewsJul.21,2025

-

PLJT-250-25 Full-auto Turntable Clipping Machine | Efficient Automation

NewsJul.20,2025

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025