دېكابىر . 07, 2024 11:57 Back to list

Automated HDAF Rotary Paper Pleating Production Line for Efficient Manufacturing

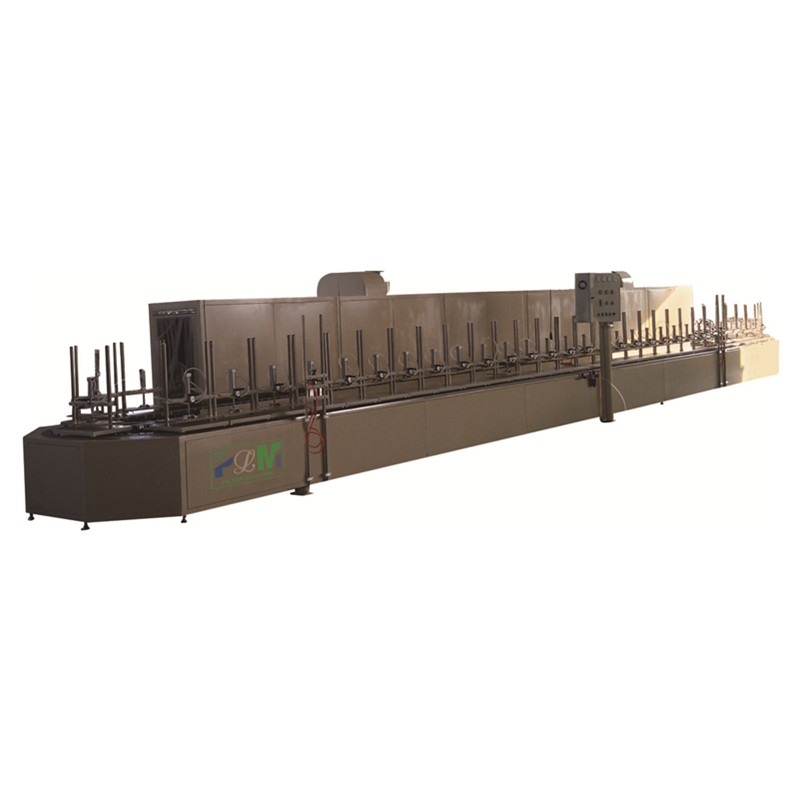

Maximizing Efficiency with the PLGT-1000N Full-Auto HDAF Rotary Paper Pleating Production Line

In the fast-paced world of manufacturing, efficiency and precision are crucial. The PLGT-1000N Full-Auto HDAF Rotary Paper Pleating Production Line stands out as a top-tier solution for businesses looking to streamline their pleating processes and enhance product quality. This innovative machine is designed to cater to the increasing demands of the paper converting industry, providing a blend of advanced technology, speed, and automation.

Understanding the Advantages of the PLGT-1000N

The PLGT-1000N is engineered for versatility and efficiency. Its full automation means that it can perform a wide array of tasks without the need for constant manual intervention. This not only reduces labor costs but also minimizes the risk of human error, ensuring that the final products meet the highest quality standards.

One of the standout features of the PLGT-1000N is its high-speed operation. Capable of producing a significant volume of pleated paper products in a short time, this machine is designed for peak performance. Businesses can greatly increase their output while maintaining superior quality, which is essential in today’s competitive market. The integration of advanced sensors and controls provides real-time monitoring and adjustments, further enhancing the machine's efficiency.

Technical Specifications and Features

The PLGT-1000N boasts a range of technical specifications designed to optimize production

1. High Production Capacity With the ability to produce thousands of pleated paper products per hour, the PLGT-1000N meets the needs of high-volume operations. 2. Precision Pleating This machine employs sophisticated technology to achieve precise pleating patterns, ensuring consistency across batches.

3. User-Friendly Interface The machine’s intuitive control panel allows operators to easily program and adjust settings, making it accessible even for those with limited technical knowledge.

buy plgt-1000n full-auto hdaf rotary paper pleating production line

4. Durable Construction Built from high-quality materials, the PLGT-1000N is designed for longevity, reducing maintenance costs and downtime.

5. Eco-Friendly Operation Designed with efficiency in mind, this machine reduces waste and energy consumption, making it an environmentally friendly choice for businesses.

Applications of the PLGT-1000N

The versatility of the PLGT-1000N means it can be used in various industries. It is particularly valuable in producing products such as pleated paper bags, surgical masks, and filters, which require high precision and consistency. As businesses in these sectors seek to improve their production capabilities, the PLGT-1000N emerges as a vital tool for meeting these needs.

Investment in the Future

Investing in the PLGT-1000N Full-Auto HDAF Rotary Paper Pleating Production Line represents a strategic move for any manufacturer looking to enhance their operational efficiency. The initial investment is often quickly recouped through increased production rates and reduced labor costs. Furthermore, the high-quality output ensures customer satisfaction and retention, vital components for growth in any business.

Conclusion

In summary, the PLGT-1000N Full-Auto HDAF Rotary Paper Pleating Production Line is a game changer in the world of paper manufacturing. Its advanced technological features, high production capacity, and user-friendly design make it an essential asset for businesses seeking to boost their efficiency and responsiveness to market demands. As industries continue to evolve, investing in such cutting-edge technology will significantly impact a company’s success in the competitive landscape. Embrace the future of paper pleating with the PLGT-1000N, and elevate your production capabilities to new heights.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025