دېكابىر . 21, 2024 23:11 Back to list

full-auto hdaf rotary paper pleating production line manufacturers

The Evolution and Benefits of Full-Auto HDAF Rotary Paper Pleating Production Lines

In the ever-evolving landscape of manufacturing, technological advancements have brought forth innovative solutions to meet the increasing demands of various industries. One such breakthrough is the Full-Auto HDAF Rotary Paper Pleating Production Line, which has revolutionized the way paper products are produced, particularly in the sectors of packaging and disposable items. This article explores the features, benefits, and the importance of this manufacturing system, as well as a look at leading manufacturers in the field.

What is a Full-Auto HDAF Rotary Paper Pleating Production Line?

The Full-Auto HDAF (High-Speed, Durable, and Automated Fabrication) Rotary Paper Pleating Production Line is an advanced manufacturing setup specifically designed for the efficient production of pleated paper products. These products are widely used in the food packaging industry, medical supplies, and consumer goods. The production line utilizes rotary technology, allowing for high-speed processing and greater flexibility in production, making it suitable for various product sizes and designs.

Key Features of the Production Line

1. High Automation One of the standout features of this production line is its high level of automation. Automated controls minimize the need for manual intervention, which not only speeds up production but also reduces the likelihood of human error.

2. Speed and Efficiency The rotary mechanism enables continuous operation, significantly increasing the throughput. High-speed production lines can generate thousands of pleated sheets per hour, catering to industries that require large volumes of products swiftly.

3. Quality Control Advanced sensors and monitoring systems ensure that every piece produced meets strict quality standards. This capability is critical for industries where product reliability and safety are paramount.

4. Versatility The production line can be adjusted to create various pleat designs and shapes, making it a flexible option for manufacturers who wish to diversify their product offerings without significant downtime or retooling.

5. Energy Efficiency Modern designs focus on minimizing energy consumption, thus reducing operational costs while maintaining high production standards.

Benefits of Using HDAF Rotary Paper Pleating Production Lines

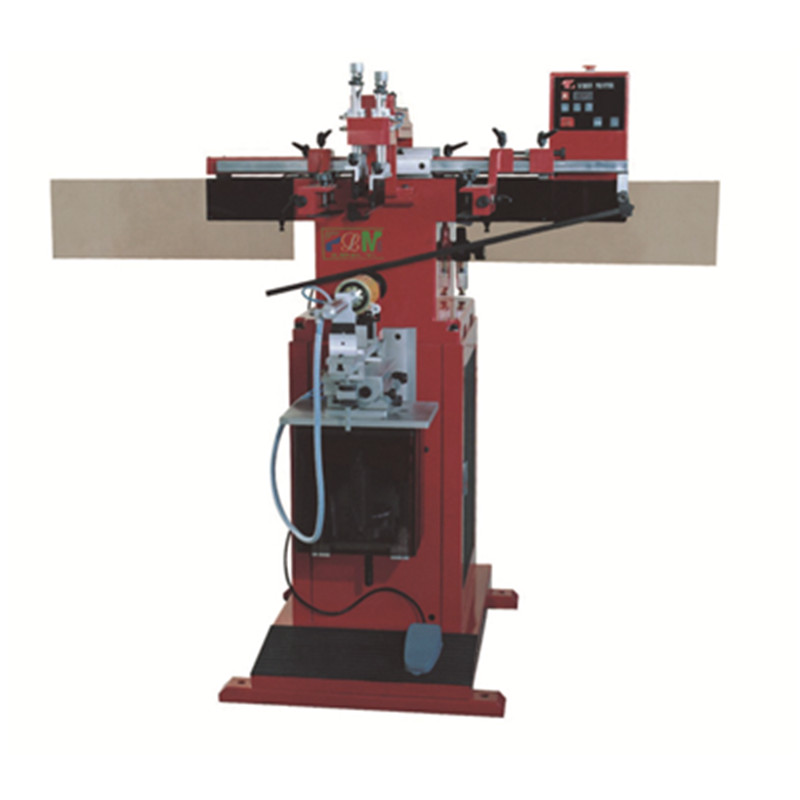

full-auto hdaf rotary paper pleating production line manufacturers

1. Cost-Effective Production By automating much of the manufacturing process, companies can reduce labor costs and increase productivity. The high-speed output allows for better scalability in production as demand grows.

2. Consistency and Quality Automated systems provide uniformity in production, which is crucial for maintaining brand reputation. Consistent quality helps companies build customer loyalty and trust.

3. Reduced Waste Enhanced precision in manufacturing processes leads to less material wastage, contributing to environmentally friendly practices while also reducing costs associated with raw materials.

4. Enhanced Safety Browsing from a human-centric approach, automated systems minimize workplace accidents related to manual handling and complex machinery, creating a safer work environment.

5. Adaptability to Market Changes Manufacturers equipped with this technology can swiftly adapt to changing market demands, such as seasonal product variations or new design trends, without incurring significant downtime.

The Future of Paper Production

As sustainability becomes increasingly important in the manufacturing process, the integration of eco-friendly materials with advanced production lines is anticipated to play a key role in the future of the paper industry. Manufacturers are compelled to innovate not only for efficiency and profitability but also for environmental stewardship.

Leading Manufacturers in the Industry

Several companies have emerged as leading manufacturers of Full-Auto HDAF Rotary Paper Pleating Production Lines. These firms combine innovative engineering with deep industry expertise, producing machines that enhance productivity while adhering to international quality standards. By prioritizing customer feedback and continuous improvement, these manufacturers are setting new benchmarks in production excellence.

In conclusion, the Full-Auto HDAF Rotary Paper Pleating Production Line represents a significant advancement in paper manufacturing technology. With its blend of automation, speed, efficiency, and quality, it is poised to meet the challenges of modern manufacturing while supporting sustainable practices in the industry. As demand for paper products continues to grow, these production lines will undoubtedly play a pivotal role in shaping the future of the paper manufacturing sector.

-

Advanced PP Spun Filter Cartridge Making Machine - Precision & Speed

NewsAug.26,2025

-

Active Carbon Air Filter for Air Purifier: Odor & VOC Control

NewsAug.25,2025

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025

-

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

NewsAug.21,2025