Dek . 18, 2024 00:33 Back to list

Automatic Cabin Air Filter Gluing Machine PLCB-500 for Efficient Production

Enhancing Air Quality The PLCB-500 Full-Auto Cabin Air Filter Gluing Machine

In today's world, where air quality is becoming an increasingly pressing concern, the automotive industry is making strides to ensure that we breathe cleaner air while driving. One significant advancement in this domain is the PLCB-500 Full-Auto Cabin Air Filter Gluing Machine. This state-of-the-art equipment plays a crucial role in the production of cabin air filters, which are vital for maintaining fresh air inside vehicles and, by extension, ensuring the health and comfort of passengers.

The Importance of Cabin Air Filters

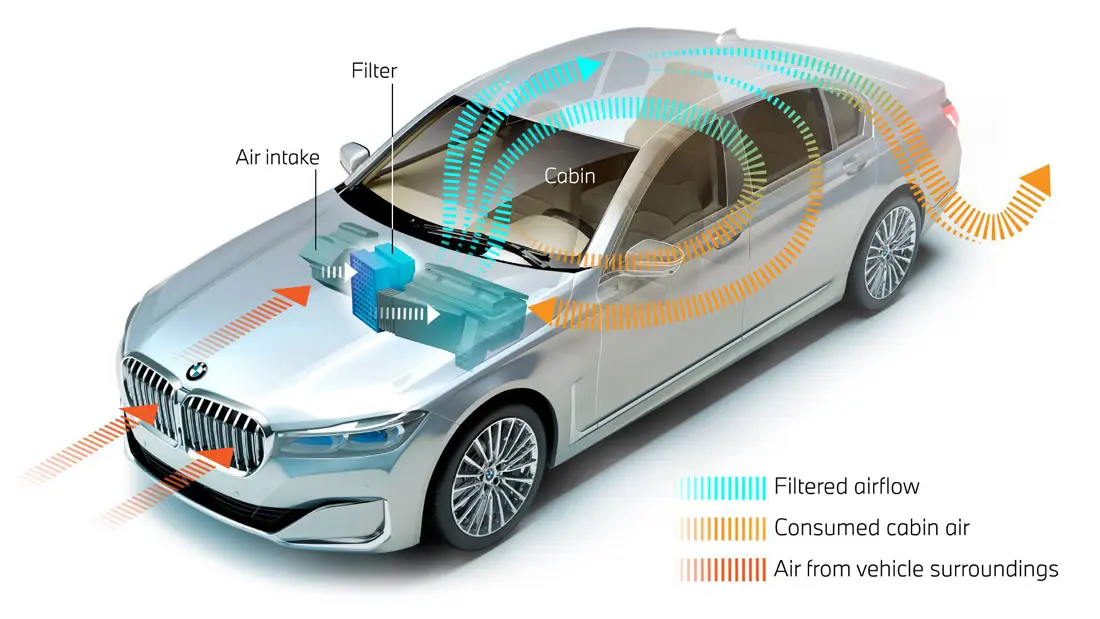

Cabin air filters are designed to trap dust, pollen, and other airborne contaminants, ensuring that the air entering the vehicle is clean and healthy. As vehicles are driven, air enters through the HVAC (Heating, Ventilation, and Air Conditioning) system. A proper cabin air filter effectively removes harmful particles, reducing the risk of allergic reactions, respiratory issues, and other health concerns related to poor air quality.

With the growing awareness of health issues associated with air pollution, the demand for high-quality cabin air filters has surged. This has necessitated the development of efficient manufacturing processes to meet industry requirements.

The Role of the PLCB-500 Machine

The PLCB-500 Full-Auto Cabin Air Filter Gluing Machine is an integral part of the production line for these filters. This machine automates the gluing process, which is critical for assembling various components of the air filters, such as the filter media, frame, and sealing elements. By ensuring a precise and uniform application of adhesive, the PLCB-500 enhances the overall quality and durability of the filters.

One of the standout features of the PLCB-500 is its fully automated operation. Automation minimizes human intervention, reducing the risk of errors associated with manual gluing. It not only speeds up the production process but also ensures consistency in adhesive application, leading to higher product quality. This efficiency translates into a higher output, enabling manufacturers to meet the increasing demand for cabin air filters effectively.

plcb-500 full-auto cabin air filter gluing mchine

2. Precision Engineering

The PLCB-500 is explicitly designed for precision. Equipped with advanced sensors and control systems, it monitors the application of glue in real-time. This capability ensures that the right amount of adhesive is used, preventing waste and optimizing the production process. Precise gluing is essential for ensuring that the filters can withstand the stresses of everyday use while maintaining their effectiveness in trapping airborne particles.

3. Versatility and Adaptability

Another remarkable feature of the PLCB-500 is its versatility. The machine can be adjusted to accommodate different sizes and types of cabin air filters, making it suitable for a wide range of applications across the automotive sector. This adaptability means that manufacturers can switch between different production runs without significant downtime, enhancing productivity and ensuring they can meet varying customer specifications.

4. Enhanced Safety Features

Given the importance of safety in manufacturing environments, the PLCB-500 incorporates various safety features to protect operators and equipment. Emergency shut-off mechanisms and protective barriers help to prevent accidents, allowing operators to work confidently and efficiently. This focus on safety also contributes to a harmonious work environment.

Conclusion

The PLCB-500 Full-Auto Cabin Air Filter Gluing Machine represents a significant advancement in the manufacturing of cabin air filters. By automating the gluing process, ensuring precision, offering versatility, and prioritizing safety, the PLCB-500 is helping manufacturers produce high-quality air filters that contribute to cleaner air in vehicles. As the automotive industry continues to evolve and prioritize air quality, machines like the PLCB-500 play an essential role in driving this crucial change.

In summary, the PLCB-500 is not just a machine; it is a linchpin in the pursuit of better air quality for future generations. As we move toward a world that increasingly values health and wellbeing, innovations in manufacturing technology will remain at the forefront, ensuring that clean air is a standard rather than a luxury in our daily driving experiences.

-

Advanced PP Spun Filter Cartridge Making Machine - Precision & Speed

NewsAug.26,2025

-

Active Carbon Air Filter for Air Purifier: Odor & VOC Control

NewsAug.25,2025

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025

-

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

NewsAug.21,2025