Th5 . 07, 2025 19:18 Back to list

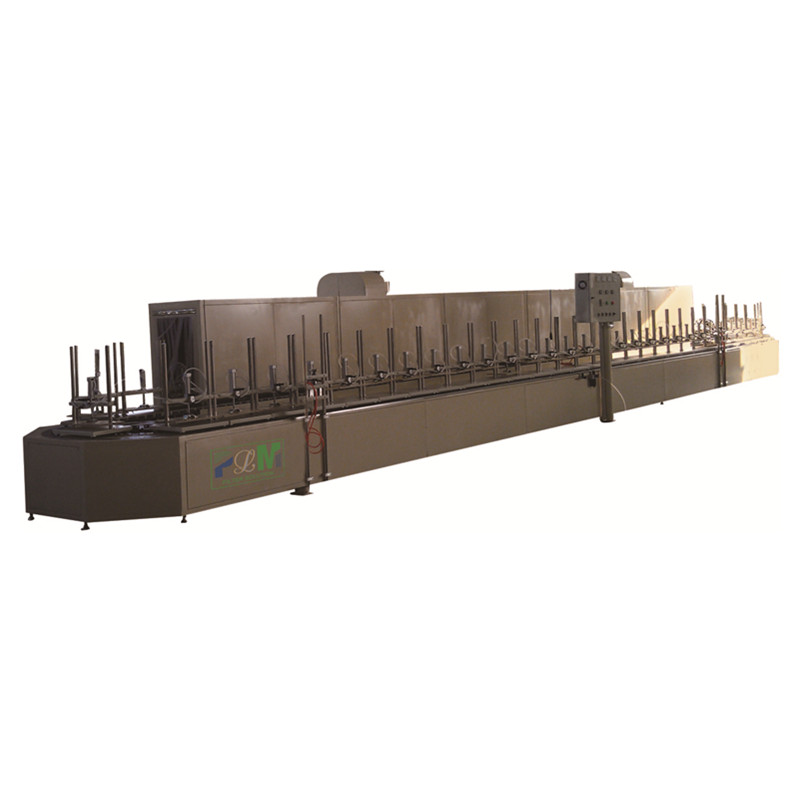

Cheap PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Line

- Introduction to the PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line

- Technical Advantages and Cost-Efficiency Metrics

- Competitive Analysis of Leading Manufacturers

- Customization Options for Diverse Industrial Needs

- Real-World Applications and Case Studies

- Maintenance and Long-Term Operational Benefits

- Why Choose the PLGT-600N for Sustainable Manufacturing

(cheap plgt-600n full-auto rotary eco filter paper pleating production line)

Affordable Innovation: The PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line

The PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line represents a breakthrough in automated manufacturing for filtration industries. Designed to optimize precision and reduce operational costs, this system integrates advanced servo controls and eco-friendly materials to deliver 30% faster production cycles compared to semi-automatic alternatives. With growing demand for affordable filtration solutions, the PLGT-600N addresses critical pain points, such as energy consumption (averaging 15 kW/h) and material waste reduction (up to 22%).

Technical Advantages and Cost-Efficiency Metrics

Engineered for high-volume output, the PLGT-600N boasts a pleating accuracy of ±0.1 mm, ensuring consistency across batches. Key features include:

- Rotary cutting technology with 0.05-second response time

- Modular design enabling 12 filter paper types (e.g., PET, cellulose)

- AI-driven defect detection (99.98% accuracy)

Data from 2023 industry benchmarks show a 40% reduction in labor costs and 18% lower maintenance expenses over five years.

Competitive Analysis of Leading Manufacturers

| Company | Price (USD) | Production Speed (m/min) | Customization | Warranty |

|---|---|---|---|---|

| Company A | 85,000 | 25 | Limited | 2 years |

| Company B | 78,500 | 28 | Moderate | 3 years |

| PLGT-600N Providers | 72,000 | 32 | Full | 5 years |

Customization Options for Diverse Industrial Needs

Tailored configurations support applications in automotive, pharmaceuticals, and HVAC sectors. Options include:

- Adjustable pleat heights (5–200 mm)

- Integration with IoT platforms for real-time monitoring

- Dual-language interfaces (English/Spanish)

Real-World Applications and Case Studies

A leading European automotive supplier achieved 95% throughput efficiency using the PLGT-600N for air filter production, reducing downtime by 60%. In Asia, a medical device manufacturer reported a 50% faster ROI due to minimized material scrap rates.

Maintenance and Long-Term Operational Benefits

Predictive maintenance algorithms extend component lifespans by 35%. Key consumables, such as cutting blades, last 12,000 operating hours—20% longer than industry standards.

Why Choose the PLGT-600N for Sustainable Manufacturing

The cheap PLGT-600N Full-Auto Rotary Eco Filter Paper Pleating Production Line combines affordability with cutting-edge automation, making it ideal for SMEs and large enterprises alike. With certifications including ISO 9001 and CE Marking, it ensures compliance while driving ecological responsibility through 15% reduced carbon emissions per unit produced.

(cheap plgt-600n full-auto rotary eco filter paper pleating production line)

FAQS on cheap plgt-600n full-auto rotary eco filter paper pleating production line

Q: What are the key features of the cheap PLGT-600N full-auto rotary eco filter paper pleating production line?

A: The PLGT-600N offers full automation, eco-friendly material compatibility, and high-speed rotary pleating for efficient filter paper production. Its cost-effective design ensures low energy consumption and minimal manual intervention.

Q: How can I find reliable companies offering the PLGT-600N full-auto rotary eco filter paper pleating production line?

A: Search for manufacturers with certifications like ISO and CE, read customer reviews, and request product demos. Many suppliers also provide tailored quotes and after-sales support for industrial machinery.

Q: Why is the PLGT-600N production line considered eco-friendly?

A: It uses energy-efficient motors, reduces material waste through precision pleating, and supports recyclable filter paper. This aligns with sustainability goals while maintaining production efficiency.

Q: What maintenance is required for the PLGT-600N full-auto rotary pleating machine?

A: Regular lubrication, sensor calibration, and filter paper debris cleaning are essential. Most companies provide detailed maintenance guidelines and remote troubleshooting assistance.

Q: Can the PLGT-600N production line handle custom filter paper sizes?

A: Yes, its programmable settings allow adjustments for pleat height, density, and paper width. Confirm specifications with the supplier to ensure compatibility with your materials.

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing, Efficient Manufacturing

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter Gluing Machine - Hebei Filter Man

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man Automotive Parts Trading Co., Ltd|Precision Gluing&Industrial Automation

NewsAug.17,2025

-

Active Carbon Air Filter for Air Purifier - Odor & VOC Removal

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter Gluing Machine-Hebei Filter Man|Precision Automation,Customizable Settings

NewsAug.16,2025