Sep . 29, 2024 21:08 Back to list

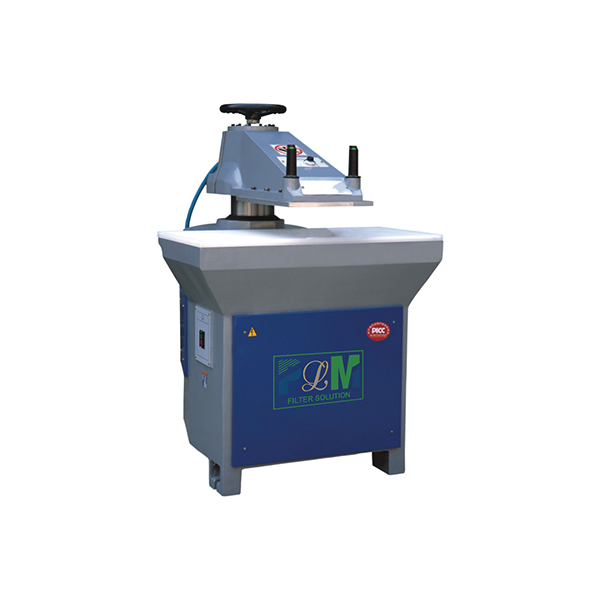

OEM PLKS-1500 Automatic PP Air Filter Plastic Injection Molding Equipment

The Advancements and Benefits of the OEM PLKS-1500 Full-Auto PP Air Filter Plastic Injection Molding Machine

In the modern industrial landscape, efficiency and precision are paramount, particularly in the production of components such as air filters. The OEM PLKS-1500 full-auto PP air filter plastic injection molding machine exemplifies the technological advancements that have revolutionized manufacturing processes. This machine is specifically designed for producing high-quality polypropylene (PP) air filters, catering to the growing demand in various sectors, including automotive, HVAC (Heating, Ventilation, and Air Conditioning), and industrial applications.

Understanding the Machinery

At the heart of the PLKS-1500’s functionality is its advanced injection molding technology. This fully automated machine streamlines the production process, allowing for consistent quality and reduced cycle times. The injection molding process involves melting plastic granules and injecting the molten material into a mold, where it solidifies into the desired shape. The PLKS-1500 is engineered to handle high throughput, making it ideal for large-scale manufacturing. Its automation features minimize human intervention, which not only enhances safety but also reduces the likelihood of errors during production.

Key Features

One of the standout features of the OEM PLKS-1500 is its versatility in handling different types of polypropylene. This is crucial for air filter production, as the material's properties must align with the specific requirements of filtration performance and durability. The machine is equipped with precise temperature control systems and advanced mold cooling mechanisms, ensuring that the final products have optimal structural integrity.

Additionally, the PLKS-1500 incorporates programmable logic controllers (PLCs) that enable operators to customize parameters for various production runs

. This flexibility allows manufacturers to switch between different air filter designs with minimal downtime. Furthermore, the machine's user-friendly interface facilitates easy operation and quick training for staff, making it an excellent investment for both new and experienced manufacturers.oem plks-1500 full-auto pp air filter plastic injection molding machine

Benefits of Full Automation

The benefits of using the PLKS-1500 extend beyond merely producing air filters. Full automation significantly increases production efficiency, leading to lower operational costs. By reducing the need for manual labor, companies can allocate resources more effectively, ultimately enhancing profitability.

Another critical advantage is the consistency and reliability of the products manufactured. Automated systems reduce human error, ensuring that each air filter meets stringent quality standards. This reliability is vital in industries where air quality and filtration systems play crucial roles, such as in automotive manufacturing, where engine performance and emissions control are directly linked to the quality of air filters.

Environmental Considerations

In today’s eco-conscious world, sustainability is a significant factor in manufacturing. The OEM PLKS-1500 machine is designed with energy efficiency in mind. Its innovative processes require less energy compared to traditional molding machines, reducing the overall carbon footprint of production. Moreover, the use of polypropylene, a recyclable material, aligns with efforts to promote environmentally friendly practices in the manufacturing sector.

Conclusion

The OEM PLKS-1500 full-auto PP air filter plastic injection molding machine represents a significant leap forward in manufacturing technology. By combining automation, precision, and energy efficiency, this advanced piece of machinery not only meets the rising demand for high-quality air filters but also supports sustainable practices in the industry. As manufacturers strive to improve efficiency and product quality, the PLKS-1500 stands out as a leading solution that paves the way for the future of air filter production. With its robust features and environmental benefits, it is poised to play a crucial role in the evolving landscape of manufacturing.

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025

-

CE Certification Auto/Truck Filter Paper Supplier – Premium Filtration Solutions for Vehicles

NewsJul.06,2025

-

OEM PLGY-500 HDAF Mesh-Ends Hooking and Pressing Machine - High Efficiency, Precision, Reliable Performance

NewsJul.06,2025