Dec . 17, 2024 12:57 Back to list

Manufacturer of High-Quality Pleated Filter Materials for Various Applications

The Importance of Pleated Filter Material Manufacturers in Modern Filtration Solutions

In today's industrial and residential environments, air and liquid filtration play crucial roles in ensuring health, safety, and efficiency. Among the various filtration technologies available, pleated filter materials have gained significant attention due to their superior performance and extensive applications. This article explores the importance of pleated filter material manufacturers, their innovations, and the impact of their products on various industries.

Understanding Pleated Filter Materials

Pleated filters are designed with a series of folds that increase the surface area available for filtration. This design optimizes the filter's ability to capture particles, gases, and contaminants, leading to improved air and liquid quality. Pleated filter materials are widely used in HVAC systems, industrial processes, automotive applications, and water treatment facilities.

The effectiveness of pleated filters is largely dependent on the materials used in their construction. Common materials include synthetic fibers, natural fibers, and activated carbon, each offering unique properties that cater to specific filtration needs. Manufacturers play a critical role in selecting and developing high-quality materials that meet industry standards and performance requirements.

The Role of Manufacturers

Pleated filter material manufacturers are at the forefront of innovation in the filtration sector. They are responsible for

1. Research and Development Manufacturers invest heavily in R&D to improve the efficiency and lifespan of pleated filters. This includes developing advanced materials that can withstand harsh operating conditions and enhancing the filtration capabilities of existing products.

2. Customization Different applications require tailored filtration solutions. Manufacturers provide customization options, allowing companies to specify the size, shape, and material of pleated filters to meet their unique needs. This flexibility is essential for industries such as pharmaceuticals, food and beverage, and chemicals, where specific contamination risks exist.

3. Quality Control Ensuring the quality of pleated filter materials is paramount. Manufacturers implement rigorous quality control measures to ensure that each filter meets performance criteria. This includes testing for particle capture efficiency, airflow resistance, and overall durability.

pleated filter material manufacturer

4. Sustainability Efforts With growing environmental concerns, many manufacturers are focusing on sustainable practices. This includes using eco-friendly materials and optimizing production processes to minimize waste. Consumers are increasingly demanding filtration solutions that not only perform well but are also environmentally responsible.

5. Technological Advancements Advances in technology have transformed the filtration industry. Manufacturers are adopting new technologies, such as nanofiber technology and electrospinning, to create filters that can capture even smaller particles without compromising airflow. These innovations lead to longer-lasting and more efficient products, benefiting users across the spectrum.

The Impact on Industries

The contributions of pleated filter material manufacturers have far-reaching implications for various industries

- Healthcare In healthcare settings, clean air and water are vital for patient safety. High-efficiency pleated filters help maintain sterile environments by trapping airborne pathogens and contaminants.

- Automotive In the automotive sector, pleated filters ensure that engines operate efficiently by preventing harmful particles from entering the combustion chamber. This not only improves performance but also extends the lifespan of vehicles.

- Food and Beverage In food processing, maintaining strict hygiene standards is essential. Pleated filters help remove particulates and microorganisms from air and liquids, ensuring that food products are safe for consumption.

- Industrial Applications Many manufacturing processes require clean air and liquids to function optimally. Pleated filters are integrated into various systems to enhance product quality and protect equipment from damage due to contaminants.

Conclusion

Pleated filter material manufacturers are integral to the development of effective filtration solutions that address the challenges of modern industries. Their commitment to innovation, sustainability, and quality control aids in protecting public health, enhancing product quality, and promoting environmental responsibility. As industries continue to evolve, the role of these manufacturers will remain crucial in delivering advanced filtration solutions that meet the ever-growing demands of society.

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025

-

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

NewsAug.21,2025

-

Premium Acrylic-Resin Air Filter Paper in Roll | High Efficiency

NewsAug.19,2025

-

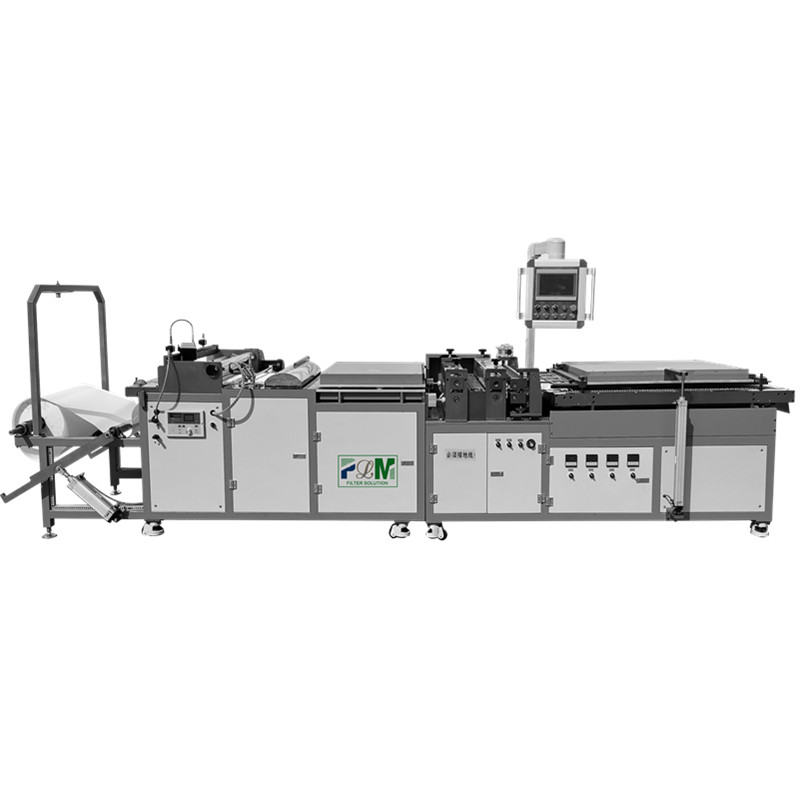

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Production

NewsAug.18,2025