Dec . 07, 2024 15:01 Back to list

Top Fiberglass HEPA Filter Producers and Their Key Offerings

The Role of Fiberglass HEPA Filter Manufacturers in Air Quality Management

In the modern world, maintaining good indoor air quality has become increasingly important for health and wellbeing. One of the most effective ways to achieve this is through the use of High-Efficiency Particulate Air (HEPA) filters, particularly those made from fiberglass. HEPA filters are essential in various applications, including residential, commercial, and industrial settings, and this is where fiberglass HEPA filter manufacturers play a pivotal role.

Understanding HEPA Filters

HEPA filters are designed to trap a minimum of 99.97% of particles that are 0.3 microns in size. This high level of filtration efficacy makes them ideal for removing allergens, dust, pollutants, and even certain pathogens from the air. Fiberglass is a popular material used in HEPA filters due to its excellent filtration properties, durability, and cost-effectiveness.

Fiberglass filters are constructed from fine strands of glass fiber, which are layered to create a dense mat. This structure not only allows for high airflow but also ensures efficient particle capture. The woven nature of the fiberglass enables it to intercept particles through multiple mechanisms such as interception, inertial impaction, and diffusion. As a result, fiberglass HEPA filters are widely used in various environments, including hospitals, laboratories, and HVAC systems.

The Importance of Manufacturers

Fiberglass HEPA filter manufacturers are crucial in the supply chain for clean air solutions. These companies are responsible for designing, producing, and distributing filters that meet stringent regulatory standards. The quality of their products directly influences air quality and, consequently, public health.

1. Research and Innovation Manufacturers invest in research and development to improve filter efficiency and longevity. New technologies and materials are being explored to enhance the performance of fiberglass HEPA filters. Innovations such as improved fiber treatments or the incorporation of additional filtration stages can significantly enhance a filter’s capability.

fiberglass hepa filter manufacturers

2. Quality Control Reputable fiberglass HEPA filter manufacturers adhere to strict quality control processes to ensure that each filter meets industry standards. This includes testing for efficiency, airflow resistance, and durability. By maintaining high-quality production standards, manufacturers assure customers that their filters will perform reliably over time.

3. Customization Different applications require different specifications when it comes to air filtration. Leading manufacturers can customize filters to suit specific needs, whether for an industrial setting or a residential home. This flexibility is vital for ensuring businesses and homeowners receive products that adequately address their unique air quality challenges.

4. Education and Support Apart from manufacturing, many companies provide educational resources and support to their clients. They inform users about the importance of regular filter replacement and maintenance to maximize performance. A lack of awareness about filter upkeep can lead to reduced air quality and increased health risks.

5. Environmental Considerations As awareness of environmental issues grows, manufacturers are also focusing on creating more sustainable filtration solutions. This includes using recyclable materials and developing filters that are longer-lasting to reduce waste. Manufacturers committed to environmentally-friendly practices contribute positively to air quality without adding to the ecological burden.

The Future of Fiberglass HEPA Filters

As air quality concerns continue to rise, particularly in urban areas plagued by pollution and allergens, the demand for effective air filtration solutions like fiberglass HEPA filters is expected to grow. Manufacturers will play a key role in addressing these challenges by developing innovative, high-performance filters that meet the needs of various sectors.

In conclusion, fiberglass HEPA filter manufacturers are instrumental in ensuring clean air for a healthier world. Their commitment to quality, innovation, and customization enables consumers to enjoy superior air quality, and their role in education and environmental responsibility is vital for sustainable practices. As we move forward, the partnership between manufacturers and consumers will be essential in maintaining and improving indoor air quality, ultimately leading to better health outcomes for everyone.

-

Premium Coffee Filter Rolling Paper: Fine Mesh for Smooth DIY

NewsAug.27,2025

-

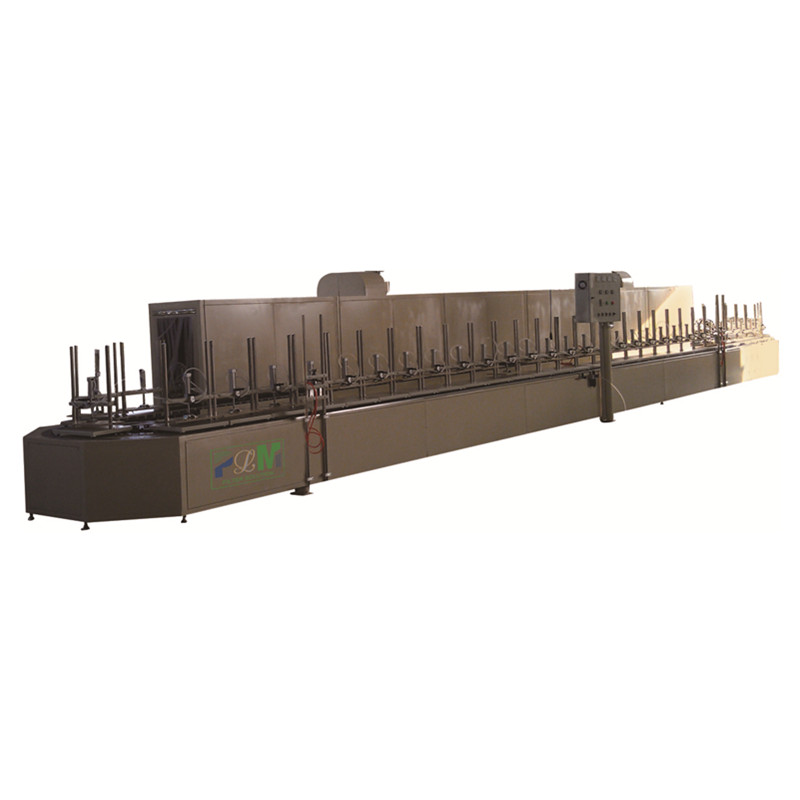

Advanced PP Spun Filter Cartridge Making Machine - Precision & Speed

NewsAug.26,2025

-

Active Carbon Air Filter for Air Purifier: Odor & VOC Control

NewsAug.25,2025

-

Premium Active Carbon Air Filter for Purifiers | Odor & VOC Removal

NewsAug.24,2025

-

Premium Active Carbon Air Filter for Air Purifier | Odor & VOC Removal

NewsAug.23,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor Removal

NewsAug.22,2025