Dec . 04, 2024 21:00 Back to list

spin-on oil filter production line products

The Spin-On Oil Filter Production Line A Deep Dive into Modern Manufacturing

In the automotive and machinery industries, the vitality of engine performance hinges significantly on effective oil filtration. Spin-on oil filters have emerged as one of the most favored types of oil filtration devices due to their ease of installation, robustness, and efficiency. The production of these indispensable components involves an intricate manufacturing process that enhances quality control and elevates productivity. This article explores the spin-on oil filter production line, its critical components, and the technological advancements shaping its future.

Understanding Spin-On Oil Filters

Before delving into the production line, it is essential to comprehend what a spin-on oil filter is. Essentially, it consists of a cylindrical metal canister that contains a filtering element. This design allows for a complete filter replacement during oil changes, making maintenance straightforward for consumers. The filter is designed to screen engine oil, capturing impurities, debris, and contaminants that could impede engine performance.

Components of the Production Line

The spin-on oil filter production line encompasses several stages, each crucial to ensuring the product's reliability and effectiveness. Here’s a breakdown of the primary components involved in this manufacturing process

1. Raw Material Preparation Quality starts with raw materials. The primary materials used in spin-on oil filters include high-grade steel for the canister and specialized filtering media, often composed of cellulose, synthetic fibers, or a combination of both. A meticulous selection process ensures durability and performance.

2. Canister Fabrication The first actual step in production is the fabrication of the metal canister. This involves stamping out metal sheets into the desired shape using advanced CNC machines. The canisters undergo processes such as bending, welding, and surface treatment to enhance corrosion resistance.

3. Filter Element Production Simultaneously, the filtering media is produced. This may involve layering different types of fibers to achieve optimal filtration efficiency. The layers are bound together using adhesives that withstand high temperatures and pressures, ensuring they perform under rigorous engine conditions.

spin-on oil filter production line products

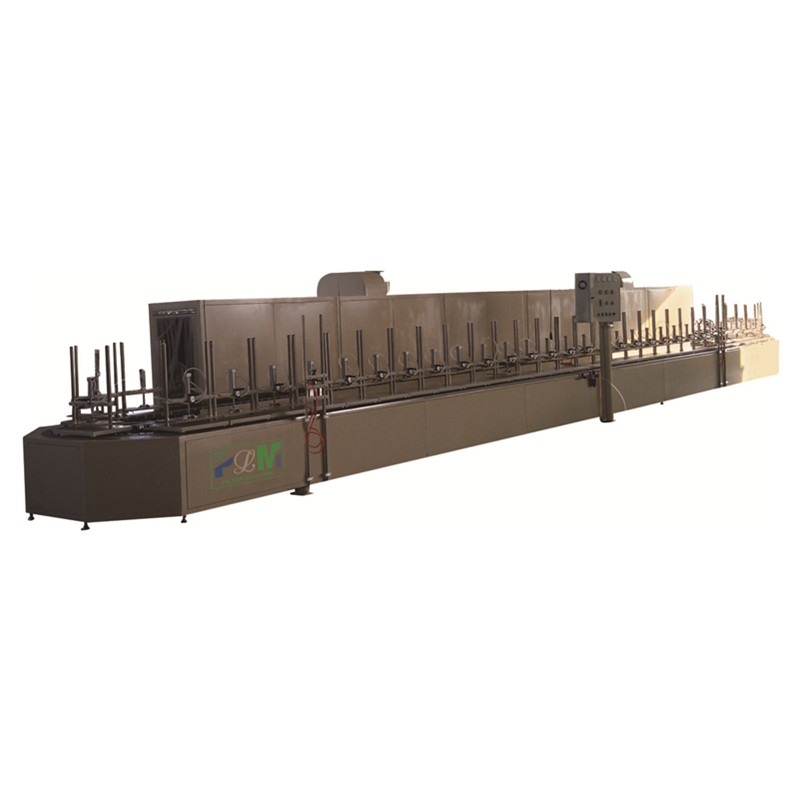

4. Assembly Line Once the individual components are ready, they are transported to the assembly line. Automated machinery plays a significant role here, streamlining the process of inserting the filter element into the canister, securing the end cap, and completing the final assembly. Robotics and conveyor systems enhance speed and reduce human error.

5. Quality Control Quality assurance is an integral part of the spin-on oil filter production line. Each batch undergoes rigorous testing, including pressure tests, flow rate assessments, and contaminant retention evaluations. Advanced sensors and imaging technologies help identify defects or irregularities, ensuring only the highest-quality filters reach consumers.

6. Packaging and Distribution Finally, the completed filters are packaged for distribution. Automated packaging lines can quickly wrap, label, and prepare products for shipment, ensuring efficiency and accuracy.

Technological Innovations in Production

The production landscape for spin-on oil filters is continually evolving, thanks to ongoing technological innovations. Industry 4.0 concepts, including IoT (Internet of Things) and AI (Artificial Intelligence), are becoming increasingly prevalent. These technologies are applied for predictive maintenance of machinery, real-time monitoring of production lines, and data analytics to improve efficiency.

Moreover, the rise of sustainable manufacturing practices has led to the exploration of eco-friendly materials and recycling methods. Circular economy principles are being integrated into the design and production processes, focusing on minimizing waste and optimizing resource use.

Conclusion

The spin-on oil filter production line represents a fascinating intersection of engineering, technology, and environmental consciousness. As vehicles evolve towards electrification and more efficient engine designs, the demand for quality filtration solutions remains paramount. Continuous improvements in manufacturing processes will undoubtedly drive innovation in this essential industry segment, ensuring that engines run smoothly and efficiently for years to come. By embracing modern technologies and sustainable practices, manufacturers can produce high-performing spin-on oil filters that meet the changing demands of the global automotive market.

-

Cheap PLJY109-500 Full-Auto HDAF Expanded Mesh Spiral Coiling Machine - High Efficiency & Quality Manufacturer

NewsJul.08,2025

-

Best PLHJ-6 Full-Auto Eco Filter Rotary Heat Plating Machine - High Efficiency & Eco-Friendly Solution

NewsJul.08,2025

-

High-Efficiency Paper Pleating Machine for Filters Trusted Filter Paper Pleating Machine Company

NewsJul.07,2025

-

High-Performance Oil Filter for Cadillac ATS – Reliable Engine Protection Solutions

NewsJul.07,2025

-

High Quality PU Glue for Filters – Reliable Filter Glue Supplier & Exporter Get PU Glue Quotes Now

NewsJul.07,2025

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025