Nov . 19, 2024 07:00 Back to list

Manufacturers of Machines for Producing Compressed Air Filters

The Importance of Compressed Air Filter Making Machines A Comprehensive Overview

In today's industrial landscape, the demand for clean and filtered compressed air is growing steadily. Compressed air is an essential utility in various sectors, including manufacturing, pharmaceuticals, food and beverage, and electronics. As industries strive for operational efficiency and quality assurance, the significance of high-quality compressed air filters has become paramount. To meet this demand, manufacturers are increasingly turning to advanced compressed air filter making machines. This article explores the importance of these machines, the production processes involved, and the key players in the market.

Understanding Compressed Air Filters

Compressed air filters are crucial components in air supply systems. They serve to remove impurities such as moisture, oil, and particulates from compressed air, ensuring that the air used in production processes is clean and suitable for various applications. Poor quality or contaminated compressed air can lead to equipment malfunctions, production downtime, and compromised product quality. Thus, investing in effective air filtering systems is critical for maintaining operational efficiency and compliance with industry standards.

The Role of Compressed Air Filter Making Machines

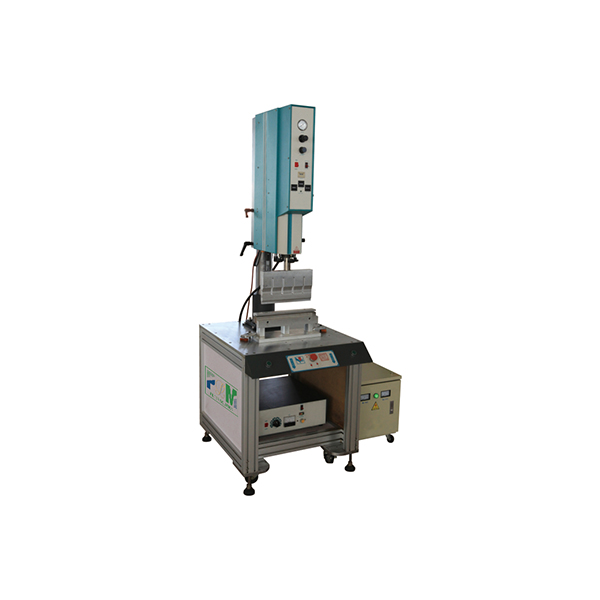

Manufacturers of compressed air filters require specialized equipment to produce filters that meet stringent performance criteria. Compressed air filter making machines are designed to automate and streamline the manufacturing process, ensuring consistency and quality in the final products. These machines typically perform various functions, including cutting, welding, assembling, and testing filter components.

1. Efficiency Advanced machines incorporate automation, allowing for high-speed production that caters to large-scale demands. This increased efficiency reduces labor costs and minimizes human error, ultimately leading to higher output quality.

2. Precision Modern manufacturing processes necessitate great precision to ensure filters meet specific dimensional and performance standards. Compressed air filter making machines utilize CNC technology and other precision tools to achieve the required tolerances.

3. Versatility Many machines are capable of producing different types of filters, including particulate filters, coalescing filters, and activated carbon filters, thus offering manufacturers flexibility in their product lines.

Key Components of Compressed Air Filter Making Machines

Several components make up these sophisticated machines, each contributing to the overall efficiency and effectiveness of the manufacturing process

compress air filter making machine manufacturers

- Cutting Mechanism High-performance cutting tools are essential for accurately shaping filter media and components. Laser cutting technology is commonly used for its precision and ability to handle various materials.

- Welding Systems Automated welding systems are employed to assemble filter components securely, ensuring structural integrity and performance reliability.

- Testing Stations Quality control is vital in filter manufacturing. Testing stations are integrated into the production line to evaluate filter performance characteristics, such as flow rate and filtration efficiency.

Leading Manufacturers of Compressed Air Filter Making Machines

The market for compressed air filter making machines has seen substantial growth, giving rise to several prominent manufacturers. These companies pioneer innovative technologies aimed at enhancing production efficiency and filter quality.

1. Kaeser Compressors Renowned for their expertise in compressed air technology, Kaeser offers machines that are designed to produce high-efficiency filters for various applications.

2. Donaldson Company A global leader in filtration solutions, Donaldson specializes in developing advanced air filtration systems and the machinery to manufacture them. Their focus on research and development ensures that their machines incorporate cutting-edge technologies.

3. Atlas Copco Known for their comprehensive range of compressed air solutions, Atlas Copco manufactures machines that enable efficient production of air filters, focusing on sustainability and resource efficiency.

4. Beko Technologies Beko is a significant player in the field, providing innovative machines for producing state-of-the-art compressed air filters that meet modern industrial standards.

Conclusion

As industries continue to prioritize quality and efficiency, the importance of compressed air filters cannot be overstated. Compressed air filter making machines play a crucial role in ensuring the production of high-quality filters that meet varying industry requirements. With advancements in technology, manufacturers can expect more efficient, precise, and versatile machines in the future, further driving the standards of air quality in industrial operations. Investing in these machines is not just a move towards operational efficiency; it is a commitment to maintaining high standards of quality and reliability in production processes.

-

AI-Optimized Active Carbon Filter for Air Purifiers | 51 chars

NewsAug.02,2025

-

Premium Active Carbon Air Filter for Air Purifiers | Odor Removal

NewsAug.01,2025

-

Activated Carbon Air Filters: Ultimate Odor Removal for Purifiers

NewsJul.31,2025

-

PP Spun Filter Cartridge Making Machine for Efficient Filtration Solutions

NewsJul.29,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor & Pollutant Removal

NewsJul.29,2025

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.28,2025