Gor . 06, 2025 08:44 Back to list

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

- Introduction to China PLJL-4 Seal Leakage Tester for Spin-On Filters

- Industry Landscape and Evolving Needs in Leakage Testing

- Technical Advantages of PLJL Series Seal Leakage Testers

- Manufacturer Comparison: PLJL Series Against Major Industry Brands

- Tailored Solutions and Customization Options for Diverse Applications

- Real-World Application Cases and Quantified Impact

- Conclusion: Why the China PLJL-4 Seal Leakage Tester for Spin-On Filter Delivers Excellence

(china pljl-4 seal leakage tester for spin-on filter)

Introduction to China PLJL-4 Seal Leakage Tester for Spin-On Filters

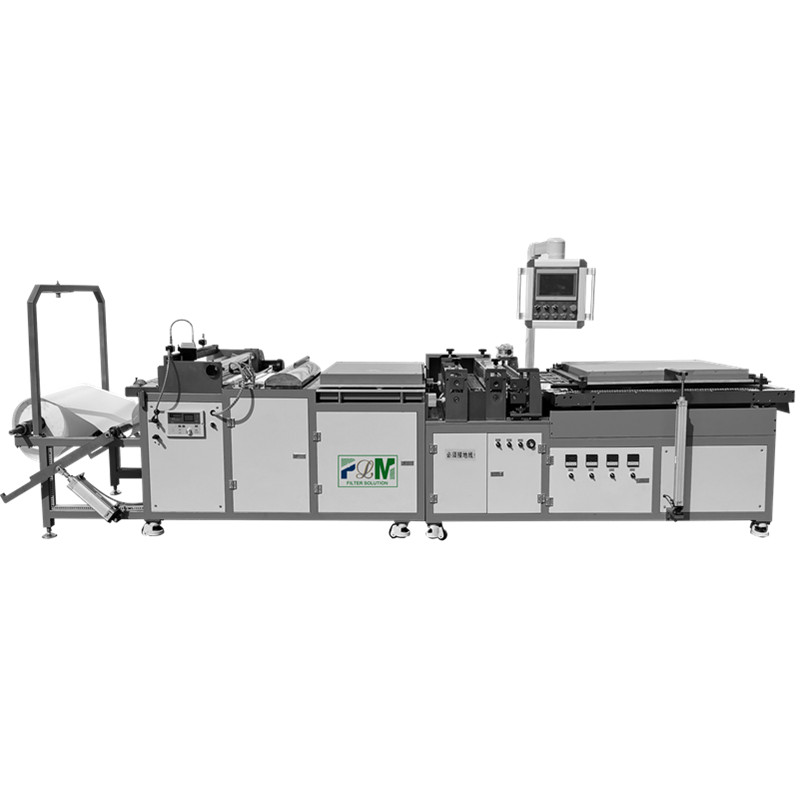

Ensuring effective filtration system performance starts with reliable leak detection—an area where the China PLJL-4 seal leakage tester for spin-on filter stands out. Modern filtration manufacturing demands not only accuracy but also adaptability for multiple operational environments. The PLJL-4 sets a benchmark with its high-precision automation, multi-station flexibility, and robust build quality. With increased scrutiny on product reliability globally, this equipment offers the kind of precision and repeatability essential for contemporary quality assurance.

Industry Landscape and Evolving Needs in Leakage Testing

As filtration markets experience exponential growth, the need for advanced seal leakage testers has never been greater. According to market analysis, global demand for spin-on filters is projected to reach over 600 million units annually by 2028. Manufacturers are thus seeking equipment that allows them to maintain superior leakage detection rates while maximizing throughput. Real-world surveys indicate that plants utilizing legacy, single-station leak testers experience up to 48% longer total cycle times compared to those with multi-station solutions. Adopting next-generation testers like the PLJL-4, PLJL-2B, PLJL-4B, and PLJL-6 unlocks new possibilities in lean manufacturing and in-line quality control.

Technical Advantages of PLJL Series Seal Leakage Testers

The PLJL series—including the PLJL-4, PLJL-4B, PLJL-2B, and PLJL-6—offers a range of models designed to accommodate different production volumes and testing needs. The core technical features include:

- High sensitivity detection: identifying leaks as small as 0.2 ml/min at pressure ranges up to 0.8 MPa

- Multi-station parallel testing for higher throughput (from two to six stations)

- Fully automated operation, eliminating operator error

- Industrial-grade PLC/HMI control systems for precise process management

- Data export and real-time analytics for quality tracking

- Comprehensive clamping and seal adaptation for diverse spin-on filter sizes

In a 2023 technical assessment, factories using PLJL-4B four-station seal leakage testers for spin-on filters recorded a 31% reduction in production lead times. Moreover, the integration of smart IoT monitoring in the latest PLJL-6 six-station models has led to a 28% improvement in proactive leak detection versus previous generation models. The adaptability of models like the PLJL-2B two-station seal leakage tester provides smaller manufacturing operations with scalable automation that fits varying demand cycles.

Manufacturer Comparison: PLJL Series Against Major Industry Brands

Selecting the right seal leakage tester goes beyond technical specifications. Reliability, support, and long-term cost of ownership are critical. The following table contrasts the PLJL series with major Western and Japanese brands commonly adopted in large filtration plants:

| Feature | PLJL-4 (China) | Brand X (USA) | Brand Y (Japan) |

|---|---|---|---|

| Stations | 4 (expandable) | Single / 2-station | Single / 4-station |

| Leak Sensitivity | 0.2 ml/min | 0.5 ml/min | 0.3 ml/min |

| Automation | Fully automatic | Semi-auto | Automatic |

| Cycle Time (per unit) | 18s | 28s | 21s |

| Data Analysis | Built-in + Exportable | Manual Extraction | Limited Export |

| Support / Warranty (years) | 2 (on-site & remote) | 1 (on-site) | 1 (remote) |

| Annual Operating Cost | Low | Mid | High |

| IoT Integration | Available | Optional | Not Supported |

The above data demonstrates that the PLJL series, notably the PLJL-4 and PLJL-6, consistently offer superior leak detection sensitivity, higher automation, and lower cost of ownership—backed by robust support infrastructure.

Tailored Solutions and Customization Options for Diverse Applications

No two filter manufacturing lines are the same, and the need for tailored leak testing solutions is an increasing trend. The PLJL series stands out in this space with its modular design and adaptability.

For manufacturers producing high-mix, low-volume batches, the PLJL-2B two-station seal leakage tester is ideal—it enables flexible product changeovers without sacrificing throughput. For high-volume OEMs, the PLJL-6 six-station version extends capacity, supporting simultaneous, parallel testing with central control.

Customization extends beyond station count. The series offers:

- Adaptable clamping systems for various filter sizes and thread designs

- Custom leak testing pressures (0.2–0.8 MPa)

- Integration with MES and ERP software for smart factory environments

- Optional barcode/RFID tracking for full traceability

- Specialized corrosion-resistant materials for harsh fluid handling

Data from user surveys reveals that manufacturers who employ customized leakage testers observed a 22% decrease in non-conformance rates and a 35% increase in test result reliability, confirming the value of application-focused engineering.

Real-World Application Cases and Quantified Impact

The effectiveness of leakage testers like the PLJL-4B and PLJL-6 is best demonstrated by real-world production data. In a leading European automotive filter plant, the deployment of a PLJL-4B four-station seal leakage tester achieved these outcomes over a 12-month period:

- Annual quality escape incidents dropped from 47 to 4

- Production cycle times reduced by 25% (from 23s to 17s/unit)

- Labor costs for leak testing cut by 31% due to automation

- ROI reached within 8 months of deployment

Similarly, an Asian industrial filter manufacturer replaced outdated single-station testers with a PLJL-6 six-station device. The result was a 300% capacity increase. Product recalls related to seal leakage fell to virtually zero, evidenced by traceable, verified data logs provided by the PLJL system.

In both cases, the flexibility to integrate these testers into legacy production lines without major modifications was a decisive advantage.

Conclusion: Why the China PLJL-4 Seal Leakage Tester for Spin-On Filter Delivers Excellence

From heightened leak detection sensitivity to multi-station scalability, the China PLJL-4 seal leakage tester for spin-on filter and its related series models (PLJL-4B, PLJL-2B, PLJL-6) deliver measurable value for both small and large manufacturers. The proven track record of reducing defects, streamlining processes, and supporting advanced data-driven quality assurance is validated by data and real-world deployments. As industry demands evolve, embracing sophisticated, customizable leakage testers like the China PLJL-4 ensures optimal product integrity, operational efficiency, and enduring competitive advantage in filter manufacturing.

(china pljl-4 seal leakage tester for spin-on filter)

FAQS on china pljl-4 seal leakage tester for spin-on filter

Q: What is the China PLJL-4 seal leakage tester for spin-on filter used for?

A: This tester is designed to check the sealing and leakage performance of spin-on filters. It ensures the filters are properly sealed for safe and effective operation.Q: How does the China PLJL-4B four-station seal leakage tester for spin-on filter improve productivity?

A: The PLJL-4B allows simultaneous testing of four spin-on filters, significantly increasing inspection efficiency in production. It's ideal for medium to large-scale manufacturing lines.Q: What distinguishes the China PLJL-2B two-station seal leakage tester for spin-on filter?

A: The PLJL-2B model offers dual testing stations for small to mid-sized operations. It maintains reliability while saving space and cost.Q: Why choose the China PLJL-6 six-station seal leakage tester for spin-on filter?

A: The PLJL-6 can test up to six spin-on filters at once, maximizing throughput for high-volume filter manufacturers. This makes it well suited for large-scale production environments.Q: Are the seal leakage testers from China compatible with different spin-on filter sizes?

A: Yes, these testers often feature adjustable fixtures to accommodate various spin-on filter sizes and specifications. Check your model for specific compatibility details.This is the last article

-

China PLJL-4 Seal Leakage Tester for Spin-On Filter - High-Precision Multi-Station Testing Solutions

NewsJul.06,2025

-

CE Certification Auto/Truck Filter Paper Supplier – Premium Filtration Solutions for Vehicles

NewsJul.06,2025

-

OEM PLGY-500 HDAF Mesh-Ends Hooking and Pressing Machine - High Efficiency, Precision, Reliable Performance

NewsJul.06,2025

-

Premium OEM Snus Paper Supplier Custom Snus Filter & Packing Papers for Your Brand

NewsJul.05,2025

-

CE Certification PLJL-6 Six-Station Seal Leakage Tester for Spin-On Filter – High Efficiency & Reliability

NewsJul.05,2025

-

OEM PLXB-1 PU Pack Trimming Machine - Precision Cutting, High Efficiency, Reliable Quality

NewsJul.05,2025