Αυγ . 21, 2025 19:00 Back to list

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

The Pivotal Role of Activated Carbon in Advanced Air Purification

In an era where air quality significantly impacts public health and industrial processes, the demand for sophisticated air filtration solutions has never been higher. Among the myriad of filtration technologies, the active carbon air filter for air purifier stands as a cornerstone for removing gaseous pollutants, volatile organic compounds (VOCs), odors, and other harmful molecular contaminants. This comprehensive overview delves into the intricate world of activated carbon filters, from their manufacturing complexities and technical specifications to their diverse applications and market dynamics.

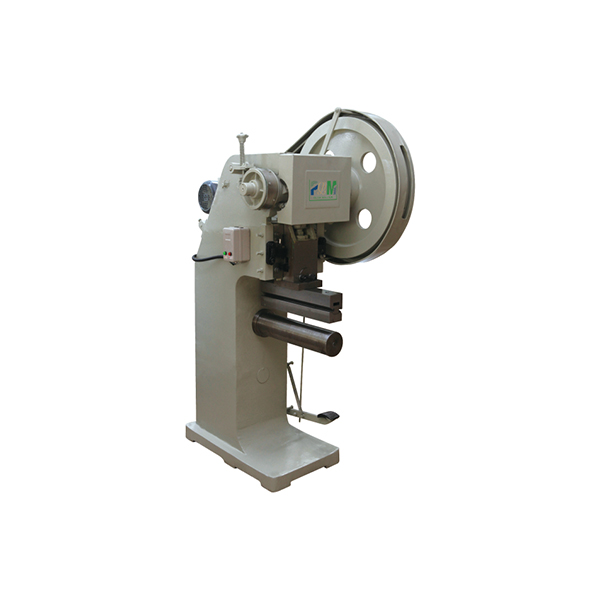

The efficacy of an activated carbon filter hinges on its high porosity and extensive internal surface area, enabling the adsorption of airborne molecules. Unlike particulate filters that trap solid particles, activated carbon operates on a molecular level, making it indispensable for environments requiring superior air purity, such as cleanrooms, healthcare facilities, and residential spaces. The precision in manufacturing, often facilitated by advanced machinery like the PLGY-500 Large Air Filter Outer Screen Hook Edge And Flattening Machine, ensures the structural integrity and performance consistency of these critical components.

Mastering the Craft: Manufacturing Process of Activated Carbon Air Filters

The production of a high-performance active carbon air filter for air purifier is a multi-stage process demanding precision engineering and stringent quality control. Understanding this manufacturing journey illuminates the sophistication behind these seemingly simple devices.

I. Raw Material Selection and Preparation

- Activated Carbon Substrate: The foundation is typically granular activated carbon (GAC), powdered activated carbon (PAC), or increasingly, fibrous activated carbon and activated carbon cloth. Common raw materials include coconut shells, wood, coal, and peat, chosen for their pore structure development potential.

- Filter Media: Non-woven synthetic fabrics (e.g., polyester, polypropylene), fiberglass, or pleated paper are often used as pre-filters or support layers to trap particulates and protect the carbon layer. Some advanced filters integrate activated carbon directly into a HEPA-grade media, as seen in a high-efficiency replacement dyson carbon hepa air filter.

- Frame Materials: Robust frames, typically made of galvanized steel, aluminum, plastic, or high-density cardboard, provide structural rigidity and facilitate installation.

II. Activated Carbon Impregnation and Treatment

For enhanced performance, activated carbon is often impregnated with specific chemicals (e.g., potassium permanganate, potassium iodide) to increase its capability to remove challenging contaminants like formaldehyde, hydrogen sulfide, or sulfur dioxide through a process called chemisorption. This differentiates it from pure physisorption and significantly extends the filter's operational lifespan in specific applications.

III. Media Fabrication and Assembly

- Carbon Bed Formation: Depending on the filter type, activated carbon can be integrated as a loose granular bed, bonded to a fibrous matrix, or formed into a rigid block, such as a honeycomb activated carbon filter.

- Pleating and Cutting: For filters incorporating pleated media (e.g., a merv 8 pleated ac furnace air filter), precision pleating machines form the media into uniform folds, maximizing surface area.

- Frame Assembly: The prepared filter media and carbon components are meticulously assembled into the chosen frame. This step often involves specialized machinery for processes like outer screen hook edge and flattening, ensuring a tight seal and structural integrity.

- Sealing: High-grade sealants (e.g., polyurethane, hot melt glue) are applied to prevent air bypass, ensuring all airflow passes through the activated carbon medium.

IV. Quality Control and Testing

Rigorous testing is paramount to ensure filters meet performance specifications and regulatory standards.

- Adsorption Capacity Tests: Measured by the Carbon Tetrachloride (CTC) adsorption value (ASTM D3467) or Iodine Number, indicating the carbon's porosity and ability to adsorb organic vapors. Higher values typically mean greater adsorption capacity.

- Pressure Drop Measurement: Evaluates the resistance to airflow. A lower initial pressure drop is desirable for energy efficiency, though it increases as the filter loads with contaminants.

- Efficiency Testing: While activated carbon primarily targets gases, combined filters are tested for particulate removal efficiency according to standards like ISO 16890 (ePM1, ePM2.5, ePM10) or ASHRAE 52.2 (MERV rating).

- Leakage Tests: Ensures the filter assembly is sealed properly, preventing bypass.

V. Typical Application Scenarios and Advantages

The advantages of a well-manufactured active carbon air filter for air purifier are significant:

- Comprehensive Odor & VOC Removal: Highly effective against a broad spectrum of gaseous pollutants, including formaldehyde, benzene, sulfur dioxide, and various unpleasant odors originating from cooking, pets, or industrial processes.

- Improved Indoor Air Quality (IAQ): Creates healthier living and working environments by eliminating harmful airborne chemicals, reducing respiratory irritations and long-term health risks.

- Energy Efficiency: Modern activated carbon filters are designed to minimize pressure drop, thereby reducing the energy consumption of HVAC systems and air purifiers.

- Corrosion Prevention: In industrial settings like petrochemical plants or wastewater treatment facilities, activated carbon filters protect sensitive electronics and equipment from corrosive gases, enhancing operational longevity.

- Extended Equipment Lifespan: By removing airborne contaminants, these filters protect the internal components of air purification systems and HVAC units, reducing maintenance needs and extending the life of the entire system.

The lifespan of an active carbon air filter for air purifier is influenced by factors such as the concentration of gaseous pollutants, air volume processed, and humidity levels. Regular replacement ensures consistent performance and optimal air quality.

Technical Parameters and Performance Benchmarks

Selecting the right active carbon air filter for air purifier requires a deep understanding of its technical specifications. These parameters define its performance capabilities and suitability for specific applications.

Key Technical Specifications of Active Carbon Air Filters

| Parameter | Description | Typical Range/Value | Relevance |

|---|---|---|---|

| Adsorption Capacity (CTC) | Carbon Tetrachloride Activity - % by weight of CTC adsorbed. Higher values indicate greater porosity and adsorption capacity. | 50% - 100% (common: 60-80%) | Directly impacts the filter's ability to remove VOCs and extend its service life. |

| Iodine Number | Measure of activated carbon activity (adsorption of iodine from solution), correlates with micropore volume. | 900 - 1200 mg/g | Indicates the surface area available for adsorption, especially for smaller molecules. |

| BET Surface Area | Brunauer-Emmett-Teller method for measuring total surface area. | 1000 - 1500 m²/g | A larger surface area allows for more adsorption sites. |

| Initial Pressure Drop | Resistance to airflow when the filter is clean, measured at a specified airflow rate. | < 150 Pa @ nominal flow | Lower values indicate better energy efficiency and reduced fan power consumption. |

| Airflow Rate (Nominal) | Recommended volume of air (CFM or m³/h) the filter is designed to handle efficiently. | Varies greatly by size and application (e.g., 200-2000 CFM) | Ensures the filter is adequately sized for the air purification system. |

| Service Life | Estimated operational lifespan before saturation or significant performance degradation. | 3-12 months (residential), 6-24 months (commercial/industrial, depending on contaminants) | Determines replacement frequency and total cost of ownership. |

| Operating Temperature Range | Temperature limits within which the filter performs optimally. | -10°C to 50°C (14°F to 122°F) | Ensures compatibility with environmental conditions. |

Industry Standards and Certifications

Adherence to international standards is crucial for guaranteeing the quality and reliability of an active carbon air filter for air purifier. Reputable manufacturers comply with:

- ISO 9001: Quality Management System certification, ensuring consistent production processes and product quality.

- ISO 14001: Environmental Management System, indicating sustainable manufacturing practices.

- ASHRAE 52.2: For particulate filtration components (MERV ratings), often integrated with carbon filters.

- EN 1822: European standard for HEPA and ULPA filters, relevant for combined carbon-HEPA filters.

- ASTM D3467: Standard test method for carbon tetrachloride activity of activated carbon.

By meticulously analyzing these parameters and ensuring compliance with recognized standards, B2B purchasers can confidently procure filters that meet their exact performance requirements and contribute to superior air quality.

Applications and Sector-Specific Impact

The versatility of the active carbon air filter for air purifier extends across a myriad of industries, addressing diverse air quality challenges.

I. Residential and Commercial HVAC Systems

In homes and offices, these filters are crucial for removing cooking odors, pet smells, cigarette smoke, and everyday VOCs from cleaning products and furnishings. They are often combined with particulate filters, such as a merv 8 pleated ac furnace air filter, to provide comprehensive indoor air quality improvements, reducing allergens and improving overall comfort.

II. Healthcare and Pharmaceutical Facilities

Hospitals, laboratories, and pharmaceutical manufacturing plants demand exceptionally clean air. Activated carbon filters play a vital role in removing anesthetic gases, sterilization odors, chemical fumes, and airborne molecular contaminants (AMCs) that could compromise sensitive processes or patient health. Precision filtration is critical, often integrating with HEPA filters to meet stringent cleanroom classifications.

III. Industrial and Manufacturing Environments

From chemical processing plants to food and beverage facilities, industrial operations often release a spectrum of gaseous pollutants. Activated carbon filters are deployed in exhaust systems to control emissions, purify intake air for sensitive equipment, and protect workers from hazardous fumes. They are integral in applications requiring robust air filtration, similar to how a fuel filter for caterpillar truck engine ensures engine longevity or an isf2 8 oil-water separator fuel filter protects heavy machinery.

IV. Automotive and Transportation

Cabin air filters in modern vehicles increasingly incorporate activated carbon to remove exhaust fumes, ozone, and other external pollutants, enhancing passenger comfort and health. While distinct from an oil filter fit for outback legacy svx car or a 37010 - auto car engine oil filter, their shared goal is critical system protection and performance. Similarly, industrial vehicle applications might use a specific fuel filter for 6.7l diesel fd4615 for engine protection, paralleling the need for air filtration for internal combustion air.

V. Data Centers and Electronic Manufacturing

Sensitive electronic components are vulnerable to corrosive gases (e.g., sulfur dioxide, hydrogen sulfide) which can cause micro-corrosion, leading to equipment failure. Activated carbon filters provide crucial molecular filtration, safeguarding uptime and reducing costly repairs. The need for pristine air quality here is as critical as ensuring clean, compressed air via an rts aliexpress way compressed air filter in pneumatic systems.

The broad applicability underscores the critical demand for high-quality, reliable activated carbon filters, whose manufacturing precision is paramount to their performance in these diverse and demanding environments.

Strategic Advantages of Superior Filtration Solutions

Investing in a high-grade active carbon air filter for air purifier yields significant strategic advantages beyond mere air purification.

I. Enhanced Operational Efficiency and Cost Savings

While the initial cost of premium filters might be slightly higher, their long-term benefits translate into substantial savings. Superior filters reduce the load on HVAC systems by efficiently removing contaminants, leading to lower energy consumption and reduced wear and tear on components. This contributes to lower maintenance costs and extended equipment lifespan, providing a compelling return on investment (ROI).

II. Compliance and Regulatory Adherence

Many industries face strict regulatory requirements regarding air emissions and indoor air quality. High-performance activated carbon filters enable businesses to meet or exceed these standards, avoiding penalties and safeguarding their reputation. This proactive approach to compliance is vital in sectors with stringent environmental regulations.

III. Protection of Sensitive Processes and Products

In industries like semiconductor manufacturing, biotechnology, and food processing, even trace amounts of airborne molecular contaminants can compromise product integrity, leading to significant financial losses. Activated carbon filtration provides the necessary protection, ensuring product purity, consistency, and yield.

IV. Improved Employee Health and Productivity

A clean, healthy indoor environment directly impacts employee well-being and productivity. By effectively removing odors, VOCs, and other airborne irritants, activated carbon filters contribute to a more comfortable and safer working atmosphere, potentially reducing absenteeism and improving overall morale.

V. Brand Reputation and Sustainability

Adopting advanced air filtration solutions demonstrates a commitment to environmental responsibility and public health. This commitment can enhance a company's brand image, attracting environmentally conscious consumers and partners. Furthermore, the longevity and efficiency of high-quality filters contribute to sustainable operations by reducing waste and energy consumption.

Manufacturer Comparison and Customization Solutions

The global market for active carbon air filter for air purifier is diverse, featuring numerous manufacturers. Choosing the right partner requires careful consideration of their capabilities, quality assurance, and ability to provide tailored solutions.

I. Key Differentiators Among Manufacturers

| Feature/Criterion | Tier-1 Manufacturer (Example) | General Manufacturer |

|---|---|---|

| R&D Investment | Dedicated R&D, patented technologies for media, impregnation processes. Focus on new material science and filter designs (e.g., honeycomb vs. granular). | Limited R&D, often replicate existing designs. |

| Quality Control & Standards | ISO 9001, ISO 14001, CE, RoHS, ASHRAE, EN standards. Internal lab testing, third-party verification. | Basic quality checks, possibly only internal standards. |

| Customization Capabilities | Extensive customization for dimensions, media type, carbon impregnation, frame materials, and specific chemical removal. (e.g., PLGY-500's flexibility in filter outer screen processing). | Limited options, primarily standard sizes and types. |

| Technical Support & Service | Pre-sales consultation, post-sales support, installation guidance, performance monitoring, dedicated account managers. | Basic sales support only. |

| Supply Chain & Production Capacity | Robust, scalable production lines, reliable material sourcing, efficient logistics, ensuring timely delivery. | Potentially limited capacity, susceptible to material shortages, longer lead times. |

Specialized machinery, such as the PLGY-500 Large Air Filter Outer Screen Hook Edge And Flattening Machine, is a strong indicator of a manufacturer's commitment to precision and high-volume production capabilities, which directly translates into consistent product quality and reliable supply for demanding B2B clients.

II. Tailored Filtration Solutions

True partnership in the filtration industry involves more than just off-the-shelf products. Leading manufacturers offer comprehensive customization, including:

- Specific Dimensions: Manufacturing filters to precise dimensions for unique system integrations.

- Custom Carbon Blends: Developing activated carbon media with specialized impregnation for targeted contaminant removal (e.g., highly effective against ammonia or specific industrial solvents).

- Integrated Solutions: Combining activated carbon layers with other filtration media, such as HEPA, pre-filters, or specialized catalytic media, to address complex air quality challenges in a single unit.

- Frame and Gasket Options: Offering various frame materials (e.g., stainless steel for corrosive environments) and gasket types to ensure optimal sealing and durability.

These customized solutions ensure that businesses receive filtration products perfectly matched to their operational needs, maximizing efficiency and protection. It's this level of bespoke engineering that defines the leaders in the filtration manufacturing space.

Real-World Impact: Case Studies and Client Success

The practical benefits of high-performance active carbon air filter for air purifier are best illustrated through real-world applications and documented success stories.

Case Study 1: Odor Control in a Wastewater Treatment Plant

A large municipal wastewater treatment facility struggled with pervasive hydrogen sulfide (H2S) and ammonia odors impacting nearby residential areas. Existing filtration systems were insufficient, leading to public complaints and potential regulatory fines. Our team designed and supplied custom-engineered activated carbon filters, specifically impregnated for enhanced H2S and ammonia adsorption. Within three months of installation, ambient air monitoring showed a 95% reduction in target gas concentrations at the facility perimeter, completely eliminating public complaints and ensuring regulatory compliance. The facility reported significant improvements in worker conditions and community relations.

Case Study 2: Protecting Electronics in a Semiconductor Manufacturing Cleanroom

A leading semiconductor manufacturer faced issues with microscopic corrosion on sensitive circuit boards, leading to reduced yields. Investigation traced the problem to airborne molecular contaminants (AMCs) like organophosphates and acid gases, even within their ISO Class 5 cleanroom. We collaborated to implement multi-stage filtration systems featuring specialized active carbon air filter for air purifier modules upstream of their HEPA filters. The activated carbon units were designed for ultra-low pressure drop to maintain cleanroom integrity. Post-installation data showed a dramatic reduction in AMC levels, leading to a 7% increase in product yield and a significant decrease in equipment downtime.

Case Study 3: Enhancing Cabin Air Quality for Public Transportation Fleet

A major city's public bus network sought to improve passenger comfort and driver health by upgrading their fleet's cabin air filtration. Traditional particulate filters were ineffective against urban air pollution, including exhaust fumes and ozone. We provided a custom solution incorporating compact, high-efficiency active carbon air filter for air purifier units specifically designed for automotive HVAC systems. Post-upgrade, driver feedback indicated a noticeable reduction in exhaust odors and improved overall air freshness. Passenger surveys also reflected higher satisfaction with the air quality during commutes, demonstrating the tangible benefits of specialized activated carbon filtration in mobile applications.

Frequently Asked Questions (FAQ)

Q1: How does an active carbon air filter for air purifier work compared to a HEPA filter?

A1: HEPA (High-Efficiency Particulate Air) filters are designed to capture solid particles like dust, pollen, mold spores, and pet dander down to 0.3 microns with 99.97% efficiency. Active carbon filters, conversely, work through a process called adsorption, where gaseous molecules (like VOCs, odors, chemical fumes) are trapped within the activated carbon's porous structure. They target different types of contaminants; often, both are used together for comprehensive air purification.

Q2: What factors influence the lifespan of an activated carbon filter?

A2: The lifespan of an active carbon air filter for air purifier is primarily determined by the concentration and type of gaseous pollutants in the air, the volume of air processed, and the humidity levels. Higher concentrations of contaminants and higher airflow rates will lead to faster saturation and a shorter lifespan. High humidity can also reduce adsorption efficiency over time.

Q3: Can activated carbon filters remove all types of gaseous contaminants?

A3: Activated carbon is highly effective against a broad range of organic compounds and many inorganic gases. However, its effectiveness varies. While excellent for VOCs, odors, and some acid gases, it may be less effective against highly polar or very small molecules like carbon monoxide (CO) or carbon dioxide (CO2). For such specific gases, specialized impregnated carbons or catalytic filters are often required.

Q4: What is the typical delivery cycle for custom or bulk orders?

A4: For standard filter products, our typical delivery cycle ranges from 2-4 weeks, depending on order volume and destination. For custom-engineered active carbon air filter for air purifier solutions, the lead time will vary based on design complexity, material sourcing, and production scheduling. We provide precise estimates upon project consultation and order confirmation. Our advanced manufacturing capabilities, supported by machines like the PLGY-500, enable efficient large-scale production.

Q5: What kind of warranty and customer support do you offer?

A5: We stand behind the quality of our products with a comprehensive 1-year limited warranty against manufacturing defects. Our dedicated customer support team is available during business hours to assist with technical queries, order tracking, and any post-purchase concerns. For our B2B partners, we offer ongoing technical consultation, performance monitoring recommendations, and expert advice to ensure optimal filtration solutions.

Conclusion: Partnering for Pristine Air Quality

The role of the active carbon air filter for air purifier is undeniably critical in achieving superior air quality across diverse sectors. From safeguarding human health and sensitive industrial processes to ensuring regulatory compliance and enhancing operational efficiency, these filters are a vital component of modern air purification strategies. The precision in their manufacturing, adherence to rigorous standards, and capacity for customization are paramount to their effectiveness.

As a professional SEO content strategist and technical writer, we understand that for B2B decision-makers and technical personnel, the choice of a filtration partner extends beyond mere product specifications. It encompasses a commitment to engineering excellence, reliable supply chains, robust quality control, and unparalleled customer support. Investing in high-quality filtration solutions, produced with advanced equipment like the PLGY-500 Large Air Filter Outer Screen Hook Edge And Flattening Machine, is not just a purchase; it's a strategic investment in long-term performance, health, and sustainability.

We are dedicated to providing the most effective and reliable activated carbon air filtration solutions, tailored to the unique demands of each client. Partner with us to achieve unmatched air purity and operational excellence.

References

- Baur, R., et al. "Activated Carbon Adsorption in Air Pollution Control." Environmental Science & Technology, vol. 45, no. 12, 2011, pp. 5122-5130.

- Choi, J. Y., et al. "A study on the performance of activated carbon filters for removing formaldehyde and toluene at various relative humidities." Journal of Environmental Management, vol. 200, 2017, pp. 317-325.

- Crittenden, J. C., et al. "Activated carbon for odor control." Water Environment Research, vol. 72, no. 1, 2000, pp. 104-111.

- Lee, J. K., et al. "Removal of Volatile Organic Compounds by Impregnated Activated Carbon Filters for Indoor Air Quality Control." Aerosol and Air Quality Research, vol. 18, no. 10, 2018, pp. 2617-2627.

- Sheldon, L., et al. "Indoor Air Quality and Activated Carbon." Applied Engineering in Agriculture, vol. 19, no. 6, 2003, pp. 741-750.

This is the last article

-

Premium Active Carbon Air Filter for Air Purifiers - Odor Removal

NewsAug.21,2025

-

Premium Acrylic-Resin Air Filter Paper in Roll | High Efficiency

NewsAug.19,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing,Automated Production

NewsAug.18,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man Automotive Parts Trading Co., Ltd | Adjustable Gluing Parameters, Automated Precision

NewsAug.18,2025

-

PLAB-6 A/B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Engineering&Efficiency

NewsAug.18,2025

-

Active Carbon Air Filter for Purifier: Superior Air Quality & Odor Removal

NewsAug.18,2025