8月 . 17, 2025 01:00 Back to list

Active Carbon Air Filter for Air Purifier - Odor & VOC Removal

The Imperative of Air Quality in Modern Environments

In an era defined by rapid industrialization and escalating environmental concerns, the demand for superior air quality solutions has reached unprecedented levels across diverse sectors. From commercial buildings and healthcare facilities to residential complexes and industrial plants, effective air purification is no longer a luxury but a fundamental necessity, directly impacting human health, operational efficiency, and regulatory compliance. Industrial trends indicate a significant push towards sustainable and high-efficiency filtration systems, driven by stricter emissions standards and a growing global awareness of airborne contaminants, including volatile organic compounds (VOCs), odors, and particulate matter. This evolving landscape underscores the critical role of advanced filtration technologies, particularly those leveraging the unique adsorptive properties of activated carbon, in mitigating a broad spectrum of atmospheric pollutants. The market's trajectory points towards innovations that integrate multiple filtration stages, ensuring comprehensive removal of both gaseous and particulate contaminants, alongside solutions tailored for specific industrial challenges like exhaust gas purification in manufacturing or ensuring clean air in sensitive electronic fabrication environments. This pervasive need elevates the importance of specialized components like the active carbon air filter for air purifier systems, which are at the forefront of this environmental protection and public health initiative, providing a robust defense against unseen threats and contributing significantly to healthier indoor and outdoor atmospheres. The strategic implementation of such advanced filtration technologies, encompassing everything from standalone air purifiers to integrated HVAC systems, represents a proactive approach to environmental stewardship and a commitment to safeguarding well-being against the backdrop of an increasingly complex pollutant landscape. This shift also emphasizes the economic benefits derived from improved worker health and reduced equipment wear, making high-quality air filtration a sound investment.

The Science and Engineering of Advanced Activated Carbon Filtration

At the core of an effective active carbon air filter for air purifier lies the principle of adsorption, a surface phenomenon where gas molecules or dissolved solids adhere to the surface of the activated carbon material. This process is distinct from absorption, where substances permeate into a bulk material. Activated carbon, often derived from materials like coal, wood, or coconut shells, undergoes a specific activation process, typically through steam or chemical treatment, which creates an extensive network of microscopic pores. These pores, categorized as micropores (less than 2 nm), mesopores (2-50 nm), and macropores (greater than 50 nm), give activated carbon an incredibly high surface area—often exceeding 1,000 square meters per gram. This vast internal surface area is crucial for trapping and retaining gaseous contaminants, including VOCs (Volatile Organic Compounds) such as formaldehyde, benzene, and toluene, along with odors like hydrogen sulfide and ammonia. The effectiveness of an activated carbon filter is largely determined by its carbon type (e.g., granular activated carbon (GAC), powdered activated carbon (PAC), or extruded carbon), iodine number (indicating micropore content), and a suitable particle size distribution to optimize both adsorption efficiency and airflow characteristics. For example, a replacement dyson carbon hepa air filter combines activated carbon with a HEPA layer for dual-action filtration of both gases and particulates. Manufacturers often enhance filter performance by impregnating the carbon with specific chemicals to improve the removal of particular gases, such as sulfur-containing compounds or ammonia, extending its applicability beyond general odor control to specialized industrial gas abatement. Understanding these intrinsic material properties and their relationship to filtration performance is paramount for selecting or designing optimal air purification systems that deliver reliable and sustained air quality improvements, addressing complex atmospheric challenges with precision engineering.

Manufacturing Process of Advanced Activated Carbon Air Filters

The production of a high-performance active carbon air filter for air purifier involves a meticulously controlled multi-stage manufacturing process, ensuring optimal functionality and longevity. The journey begins with the selection of premium raw materials, typically high-grade activated carbon sourced for its specific pore structure and adsorption capacity, often in granular or pelletized form. The manufacturing workflow then progresses through several critical stages: material preparation, where the activated carbon is sometimes pre-treated or impregnated with catalysts like potassium permanganate or proprietary chemical blends to enhance its selectivity for specific gaseous contaminants, such as hydrogen sulfide or volatile organic compounds; next, the carbon is often integrated into various filter media designs. This can involve embedding it within non-woven synthetic fibers to form a pleated structure, typical for a merv 8 pleated ac furnace air filter, or creating dense beds of granular carbon within specialized cartridges. For honeycomb designs, as seen in a honeycomb activated carbon filter, the activated carbon is precisely formed into a cellular matrix that maximizes surface area and minimizes pressure drop. Manufacturing processes for these forms include advanced techniques such as precision molding, controlled compaction, and automated assembly to ensure uniformity and structural integrity. Critical quality control points are implemented throughout the process, adhering strictly to international testing standards such as ISO 16890 and ANSI/ASHRAE 52.2, which specify procedures for measuring filtration performance including initial efficiency, pressure drop, and dust holding capacity. The finished filter elements undergo rigorous testing for air permeability, mechanical strength, and, crucially, adsorption capacity against target gases, with advanced analytical instruments verifying the filter's ability to remove specific VOCs or odors. This stringent adherence to quality and precision in manufacturing ensures that each filter meets exacting performance specifications, promising a reliable service life and consistent contaminant removal efficiency for applications spanning from petrochemical processing and pharmaceutical cleanrooms to commercial HVAC systems and critical air purification in data centers, ultimately delivering superior indoor air quality and extending the operational life of associated equipment by minimizing particulate and gaseous buildup.

Key Technical Specifications and Performance Metrics

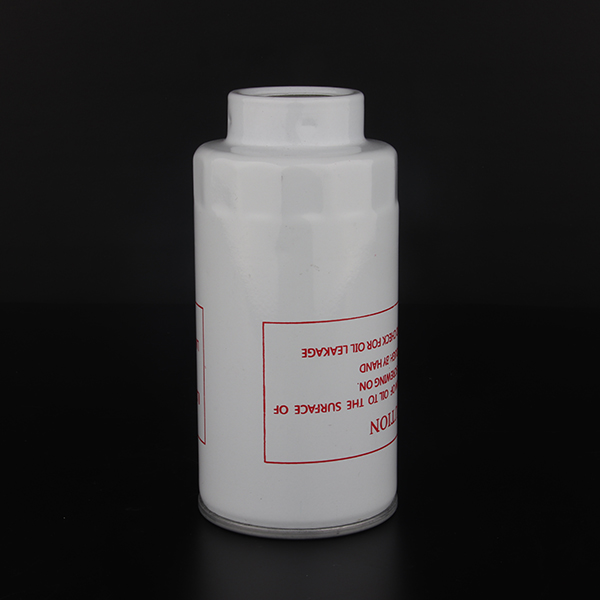

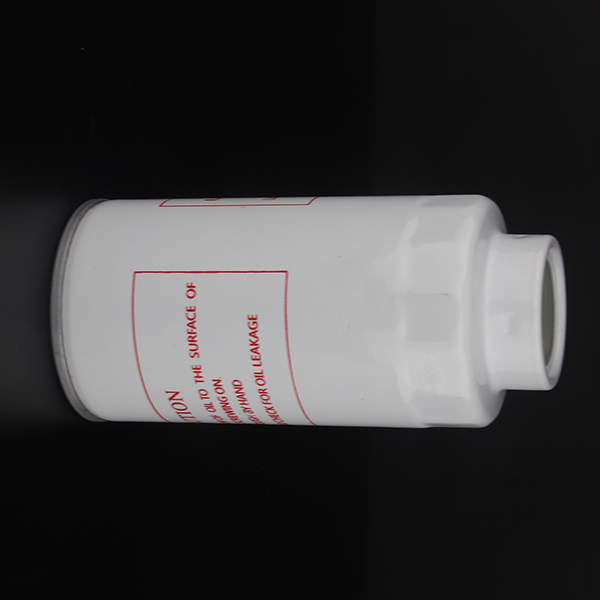

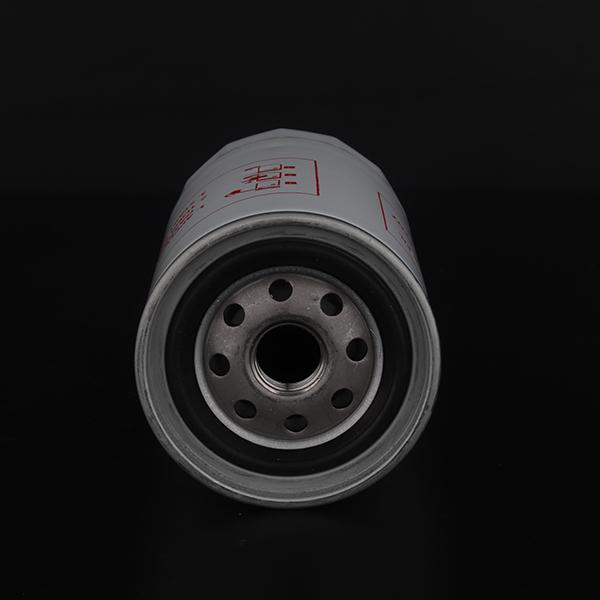

The efficacy of an active carbon air filter for air purifier is quantified through a suite of technical specifications and performance metrics, critical for B2B decision-makers assessing their suitability for industrial or commercial applications. Key parameters include the filter's Clean Air Delivery Rate (CADR), which measures the volume of clean air produced per minute, and its adsorption capacity, typically expressed in grams of pollutant per gram of activated carbon, indicating the filter's lifetime for specific contaminants. Pressure drop across the filter is another vital metric, directly influencing energy consumption of the air handling unit; a lower pressure drop translates to reduced operational costs and improved system efficiency, a primary concern in sectors like metallurgy and chemical processing. The filter's overall dimensions, including face area and depth, determine its compatibility with existing HVAC infrastructure or standalone air purifier units. Furthermore, the average service life, often ranging from 6 to 12 months depending on ambient pollutant levels and airflow rates, is a crucial factor in maintenance planning and total cost of ownership. Beyond active carbon filters, other filtration systems, like an oil filter fit for outback legacy svx car or a fuel filter for caterpillar truck engine, also rely on precise engineering of flow rates, particle retention, and material compatibility to achieve their specific performance goals. For instance, the isf2 8 oil-water separator fuel filter is designed to separate immiscible liquids, requiring distinct material properties and filtration mechanisms compared to air filters. The table below outlines typical performance parameters for a high-efficiency activated carbon air filter, providing a quantitative basis for comparison and selection. These metrics are fundamental for engineers and procurement specialists to ensure the chosen filtration solution aligns perfectly with the operational demands, environmental conditions, and specific contaminant challenges prevalent in their respective industries, optimizing both air quality outcomes and long-term economic viability.

Versatile Applications and Industry-Specific Advantages

The adaptability and effectiveness of an active carbon air filter for air purifier systems enable their deployment across an extensive range of industries, each benefiting from its specific advantages in enhancing air quality and operational efficiency. In the petrochemical sector, these filters are indispensable for removing hazardous VOCs, H2S, and other toxic gases from process streams and ambient air, thereby protecting personnel, preventing corrosion of sensitive equipment, and ensuring compliance with stringent environmental regulations. Similarly, the metallurgy industry utilizes activated carbon filters to manage fumes and odors generated during smelting and casting operations, improving workplace safety and maintaining air purity within production facilities. For the public utility sector, particularly in water supply and drainage systems, specialized activated carbon filters are essential for odor control at pumping stations and wastewater treatment plants, contributing to community well-being and reducing environmental impact. Beyond these heavy industries, active carbon filters are crucial in commercial and residential HVAC systems for eliminating indoor air pollutants such as cooking odors, pet dander, and general VOCs, significantly improving indoor air quality and occupant comfort. They are also integral to cleanrooms in the electronics and pharmaceutical industries, where even trace amounts of gaseous molecular contaminants can compromise product integrity. The inherent advantages of using these filters include substantial energy savings by preventing the need for excessive ventilation with outdoor air, superior anti-corrosion properties by removing corrosive gases that could damage HVAC components or electronic circuitry, and their cost-effectiveness over the filter’s lifespan due to high adsorption capacity. This broad applicability underscores the activated carbon filter's role as a versatile and essential component in modern air purification strategies, from a rts aliexpress way compressed air filter protecting pneumatic tools from oil aerosols and moisture, to a fuel filter for 6.7l diesel fd4615 ensuring engine longevity, all reflecting a deep commitment to environmental responsibility and operational excellence.

Customization and Tailored Filtration Solutions

Recognizing that no two industrial or commercial environments are identical, the provision of customized filtration solutions is a cornerstone of advanced air purification strategies. While standard active carbon air filter for air purifier units offer broad utility, complex contaminant profiles or unique system constraints often necessitate bespoke designs. This customization can involve altering the activated carbon type to specifically target certain chemical compounds, such as impregnated carbon for enhanced H2S removal, or varying the physical form factor of the filter media to integrate seamlessly into existing HVAC systems or proprietary air purification equipment. For instance, a client requiring odor removal in a confined space within a food processing plant might need a compact, high-density carbon filter, whereas a large-scale industrial exhaust system might require modular carbon banks designed for high flow rates and prolonged service life. Our expertise extends to engineering filters with specific pressure drop characteristics to optimize energy consumption, and to incorporating pre-filtration stages for particulate matter to extend the life of the activated carbon. This tailored approach ensures maximum efficiency and cost-effectiveness, moving beyond a one-size-fits-all model to address the precise challenges faced by our B2B partners. We engage in a detailed consultation process, analyzing client-specific air quality data, operational parameters, and regulatory requirements to develop an optimal filtration solution. This includes selecting the ideal adsorbent, designing the physical filter configuration, and predicting service life under specific conditions. Whether it's a specialized filter for a medical facility requiring sterile air or a robust solution for heavy industrial applications needing a durable filter, akin to how specific filters like the 37010 - auto car engine oil filter are engineered for particular vehicle types, our commitment is to deliver precision-engineered, high-performance filtration that aligns perfectly with the unique demands of each application, ensuring both immediate air quality improvements and long-term operational sustainability.

Authoritativeness and Trustworthiness: Our Commitment to Quality

Our position as a leading provider of filtration solutions is underscored by an unwavering commitment to quality, backed by rigorous industry certifications, extensive service experience, and transparent business practices. Every active carbon air filter for air purifier we supply is manufactured under strict quality management systems, evidenced by our ISO 9001 certification, ensuring consistent product performance and reliability. Our products frequently meet or exceed international standards such as ANSI, ASME, and in specialized cases, even FDA requirements for certain applications, reflecting our dedication to the highest benchmarks of quality and safety. We have cultivated enduring partnerships with major industrial clients across petrochemical, manufacturing, and commercial sectors over our extensive service history, consistently delivering high-performance filtration solutions that solve complex air quality challenges. Our internal testing laboratories are equipped with advanced analytical instrumentation to conduct comprehensive performance evaluations, including gas adsorption capacity tests, pressure drop measurements, and media integrity assessments. We pride ourselves on the meticulous collection and presentation of test data, offering clients transparent insights into the real-world performance of our filters. Our trustworthiness is further cemented by clear and comprehensive documentation regarding delivery lead times, typically ranging from 2-4 weeks for standard orders and custom solutions based on project complexity, ensuring predictable project timelines. We provide robust warranty commitments on all our filters, covering manufacturing defects and ensuring peace of mind for our clients. Furthermore, our dedicated customer support team is available to provide expert technical assistance, from initial consultation and system design to post-installation support and maintenance advice, ensuring a seamless and satisfactory experience. This holistic approach, combining certified quality, proven experience, authoritative testing, and dedicated support, establishes a foundation of trust that is critical for long-term B2B relationships and assures clients of receiving superior filtration technology.

Frequently Asked Questions (FAQ)

Q1: How often should an active carbon air filter for air purifier be replaced?

The replacement frequency for an activated carbon air filter largely depends on the specific application, the concentration of airborne pollutants, and the operational hours of the air purification system. In general industrial or commercial settings with moderate pollution, a filter might last between 6 to 12 months. However, in environments with high levels of VOCs, odors, or other gaseous contaminants, such as chemical plants or manufacturing facilities, replacement may be necessary every 3 to 6 months. Indicators such as noticeable re-emergence of odors or a significant increase in differential pressure across the filter can signal the need for replacement. Regular monitoring of air quality and differential pressure is recommended to optimize replacement schedules, ensuring continuous peak performance and preventing system inefficiency. Our technical support team can assist in developing a tailored maintenance schedule based on your specific operational parameters.

Q2: Can activated carbon filters remove all types of airborne pollutants?

While highly effective at removing a broad spectrum of gaseous contaminants, including Volatile Organic Compounds (VOCs), odors, and certain toxic gases, active carbon air filter for air purifier systems are less effective at filtering out particulate matter such as dust, pollen, and bacteria on their own. For comprehensive air purification, activated carbon filters are typically combined with high-efficiency particulate air (HEPA) filters, as seen in many advanced air purifier units, to ensure the removal of both gaseous and particulate pollutants. This multi-stage filtration approach provides a holistic solution for indoor air quality, addressing both molecular and microscopic solid contaminants, ensuring that environments from medical facilities to industrial cleanrooms meet stringent air purity standards. We recommend a layered approach to filtration to ensure optimal air quality for any given scenario.

Q3: What testing standards apply to these filters?

Our active carbon air filter for air purifier products adhere to various international and industry-specific testing standards to validate their performance and quality. Key standards include ISO 16890, which replaced EN 779, for general ventilation air filters and specifies testing methods for particulate filtration efficiency (though carbon filters are primarily for gas, they are often part of a system conforming to this); and ANSI/ASHRAE 52.2, which outlines methods for testing the performance of general ventilation air cleaning devices for removing particles. For gaseous filtration, performance is often evaluated against specific chemical challenges, with methodology varying by application, aligning with relevant industry best practices. Depending on the application, other standards like ISO 14644 (for cleanrooms) or specific ASTM standards for activated carbon properties (e.g., iodine number, pore volume) may also apply. Our products are rigorously tested in compliance with these standards, ensuring transparent and verifiable performance data for our clients.

References

- ISO 16890:2016 - Air filters for general ventilation — Part 1: Technical specifications, requirements and classification system based on particulate matter (PM).

- ASHRAE Standard 52.2-2017 - Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size.

- Activated Carbon for Air and Gas Purification - Principles and Applications in Industrial Systems.

- Environmental Protection Agency (EPA) - Indoor Air Quality Guidelines and Regulations.

- International Journal of Environmental Research and Public Health - Studies on Activated Carbon Adsorption Mechanisms.

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine - Hebei Filter Man

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man|Precision Gluing, Efficient Manufacturing

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter Gluing Machine - Hebei Filter Man

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter End Cap Gluing Machine-Hebei Filter Man Automotive Parts Trading Co., Ltd|Precision Gluing&Industrial Automation

NewsAug.17,2025

-

Active Carbon Air Filter for Air Purifier - Odor & VOC Removal

NewsAug.17,2025

-

PLAB-6 A B Two Compounds Filter Gluing Machine-Hebei Filter Man|Precision Automation,Customizable Settings

NewsAug.16,2025