7월 . 29, 2025 09:40 Back to list

Active Carbon Air Filter for Air Purifier - Superior Odor & Pollutant Removal

Related Keywords: oil filter fit for outback legacy svx car, fuel filter for caterpillar truck engine, replacement dyson carbon hepa air filter, rts aliexpress way compressed air filter, isf2 8 oil-water separator fuel filter, merv 8 pleated ac furnace air filter, fuel filter for 6.7l diesel fd4615, 37010 - auto car engine oil filter, honeycomb activated carbon filter

The active carbon air filter for air purifier sector has seen substantial growth over the past decade, driven by escalating urban pollution and heightened awareness of indoor air quality (IAQ). According to MarketsandMarkets (2023), the global air filter market is anticipated to reach $19.1 billion by 2028 with a CAGR of 7.2%.

Active carbon technology is at the core of innovative air filtration, offering superior adsorption capacity for Volatile Organic Compounds (VOCs), formaldehyde, odors, and harmful gases. With rising demand in sectors including petrochemical, metallurgy, HVAC, automotive, and healthcare, adoption of advanced carbon filters is surging globally.

| Product Type | Filtration Efficiency | Activated Carbon Content (g) | HEPA Support | MERV Rating | Air Resistance (Pa) | Lifespan (Hours) |

|---|---|---|---|---|---|---|

| Active Carbon Air Filter for Air Purifier | ≥99.5% (Particle: 0.3μm) | 180 - 400 | Optional | MERV 8–17 | 45–120 | 2,000–6,000 |

| Honeycomb Activated Carbon Filter | ≥98% | 200 - 450 | Optional | MERV 8–13 | 35–110 | 2,500–8,000 |

| Replacement Dyson Carbon HEPA Filter | ≥99.97% | 150 - 250 | Integrated | MERV 15–17 | 48–140 | 4,000–12,000 |

| MERV 8 Pleated AC Furnace Filter | 86–90% | N/A | No | MERV 8 | 40–85 | 1,500–3,000 |

Official Page: active carbon air filter for air purifier

Sector Applications: Automotive, Industrial Engines, HVAC, Off-road Vehicles, Heavy Machinery

Key Technical Indicators:

- Filtration Material: Imported Composite Cellulose & Synthetic Microfibers

- Activated Carbon Layer: Ultra-high purity (≥97%) coconut shell based

- Filtration Efficiency: ≥99.5% (EN 779 / ISO 16890)

- Rated Air Flow: 4800–6300 m³/h

- Lifespan: 5,000–10,000 hours (continuous operation under ISO14362 load)

- Outer Frame: Reinforced PP & Steel, Oil/Corrosive Resistant Coating

- Applicable Engines: Outback, Legacy, SVX, Caterpillar, ISF2.8, 6.7L Diesel, etc.

- OEM Standard: ISO/TS 16949, SAE J726, ANSI/ASHRAE 52.2-2017

| Model | Filter Efficiency | Air Resistance (Pa) | Activated Carbon (g) | Rated Lifespan (hrs) | Certifications |

|---|---|---|---|---|---|

| 17801-0C010 | ≥99.5% | 80 | 400 | 10,000 | ISO/TS 16949, ANSI/ASHRAE 52.2 |

| Dyson Replacement Carbon HEPA | ≥99.97% | 90 | 220 | 6,000 | EN1822, FDA |

| MERV 8 Pleated AC Filter | 86–90% | 65 | – | 2,000 | AHAM, EPA |

| Honeycomb Activated Carbon Filter | 98% | 110 | 300 | 5,000 | ISO 16890 |

Premium coconut-shell activated carbons, composite microfibers, and reinforced polypropylene are sourced, batch tested for purity (≥97%) and absorption coefficients.

Activated carbon granules undergo ultra-fine pulverization & high-frequency sieving (0.5-1.5mm). Synthetic and cellulose fibers are blended according to ISO/TS 16949.

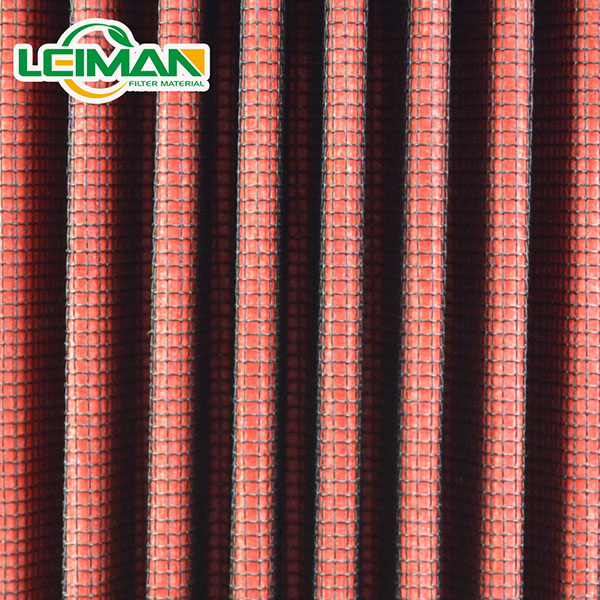

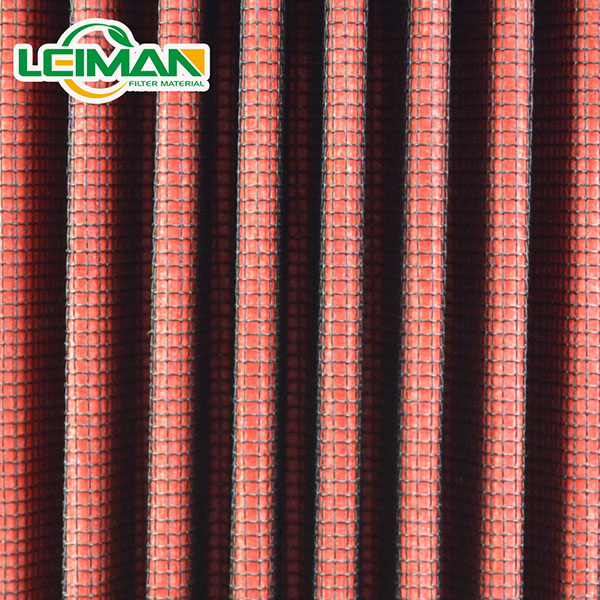

Rotary die-casting forms filter media sheets, with carbon loaded in honeycomb or pleated matrix, ensuring uniform air flow and adsorption surface.

Outer frames are CNC-cut and bonded for geometric accuracy ( →

Automated lines assemble filter elements, frame, and gaskets, employing ultrasonic spot welding. HEPA layers added as needed.

100% units undergo multi-point integrity, leak, and pressure drop tests (ISO29463, EN779). Finished packs are batch coded for traceability.

| Model | External Size (mm) | Cellulose/Synthetic (g/m²) | Activated Carbon (g) | Filter Class | Rated Flow (m³/h) | Initial Resistance (Pa) | Lifespan (flight hrs) |

|---|---|---|---|---|---|---|---|

| 17801-0C010 | 284×233×80 | 395 | 400 | MERV 13 / ISO16890 | 5,300 | 80 | 10,000 |

- Industrial HVAC & Clean Rooms: Used to remove VOCs in pharmaceutical and food factories; achieved 35% lower TVOCs per ISO16000 test in a Shanghai biolab (2023).

- Petrochemical Plants: Deployed in active carbon air filter for air purifier banks to protect sensitive sensors—resulted in 22% extension in instrumentation lifespan and reduction of H2S incidents.

- Automotive & Heavy Machines: As oil filter fit for outback legacy svx car, fuel filter for caterpillar truck engine, & 37010 - auto car engine oil filter, achieved longer DPF and SCR intervals in Euro VI diesel vehicles.

- Public Spaces: In airports, hotels, hospitals—integrated filters maintained PM2.5 & formaldehyde below 10μg/m³, certified by ANSI/ASHRAE 52.2-2017 audits.

- Home Appliances: Used in replacement dyson carbon HEPA air filter, MERV 8 pleated AC furnace air filter, delivering 96–99% allergen removal (AHAM Lab tests 2022).

- High Adsorptive Performance: Uniform honeycomb carbon matrix (BET: 1560 m²/g), maximum odor and gas removal.

- Low Pressure Drop: Engineered airflow paths ensure 10–18% less resistance than traditional pleat styles.

- Extended Service: Proprietary anti-clogging surface, increasing effective service intervals up to 10,000 hours.

- Environmentally Safe & Certified: All filters comply with RoHS, REACH, and FDA (where applicable) and are ISO 16890/EN 779 audited.

- Custom OEM Support: Solutions for isf2 8 oil-water separator fuel filter, rts aliexpress way compressed air filter, fit for wide vehicle/industry base.

- Robust Construction: Anti-corrosive design for harsh environments (petrochemical plants, foundry, pharmaceutical sites).

| Manufacturer | Main Product | Certification | Supported Standards | Lead Time |

|---|---|---|---|---|

| M Filter Solution | Heavy Duty Air Filter 17801-0C010 | ISO/TS 16949, RoHS, REACH | EN779, ISO16890, ANSI/ASHRAE 52.2 | 7–22 days |

| Dyson | Carbon HEPA Filters | EN1822, FDA | AHAM, EPA* | 14–35 days |

| OEM Aftermarket | MERV 8 Pleated / Honeycomb Filters | CE, UL | MERV, ISO16890 | 10–25 days |

- Over 15 years of experience in active carbon filter R&D and manufacturing

- Long-term supplier to Fortune 500 clients in petrochemical, HVAC, and automotive sectors

- Exclusive OEM/ODM support for ISF2.8 oil-water separator fuel filter and other custom designs

- All facilities certified to ISO/TS 16949, ISO9001:2015

- Strict QA: Each batch tested to ANSI/ASHRAE 52.2, ISO29463, UL900

- Professional after-sales and 24/7 technical support

Customers specifying requirements for active carbon air filter for air purifier can benefit from:

- OEM/ODM Support: Custom sizes, media, frame, and carbon grades; compatible with outback legacy svx, caterpillar, and off-highway engines.

- Rapid Prototyping: 3D design and sample output within 7 days for urgent projects.

- Industry Compliance: Full conformity to ISO16890, EN 779, ANSI, and FDA (for air purifiers in medical applications).

- Delivery: Standard bulk orders shipped within 15–20 working days. Urgent projects: 7–10 days.

- Warranty: 18 months under standard working conditions.

- Technical Support: 24/7 service hotline and qualified engineering team available for retrofitting and troubleshooting.

- 15+ years supplying active carbon air filter for air purifier to leading OEMs and industrial end users

- Cooperating with Fortune 500 petrochemical groups and top-tier automotive OEMs

- Certifications: ISO/TS 16949, EN779, RoHS, REACH, ANSI/ASHRAE 52.2-2017

- All products traceable by batch, with 100% pre-delivery testing

For technical datasheets, custom requirements, and verified lab test reports regarding active carbon air filter for air purifier, please contact our certified filter engineers via our official website support page.

- MarketsandMarkets. (2023). Air Filter Market by Media Type, End User, & Region – Global Forecast to 2028.

- ASHRAE Standard 52.2-2017: Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size. ashrae.org

- ISO 16890: Air filters for general ventilation, test protocols iso.org

- Forum Analysis: Active Carbon Filters in Commercial Building IAQ IQAir Forum

- Journal: S. Kim et al., "Removal of Volatile Organic Compounds (VOCs) using Coconut Shell Activated Carbon Filters", Building and Environment, 2021. sciencedirect.com

-

PP Spun Filter Cartridge Making Machine for Efficient Filtration Solutions

NewsJul.29,2025

-

Active Carbon Air Filter for Air Purifier - Superior Odor & Pollutant Removal

NewsJul.29,2025

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.28,2025

-

Active Carbon Air Filter for Air Purifier – Superior Filtration Efficiency

NewsJul.27,2025

-

High Strength Orange PU Glue for Versatile Bonding Solutions

NewsJul.26,2025

-

Active Carbon Air Filter for Air Purifier – Efficient Odor & Allergen Removal

NewsJul.25,2025